Flexible Pavement Distress—Visual Rating

Flexible pavement deterioration is exhibited in any combination of the following distresses.

Raveling. Raveling, as shown in Fig. 3.31, is the result of loss of small aggregates from the pavement surface. Raveling can be caused by oxidation of the mix, improper mix design, segregation, or lack of compaction.

Bleeding. Bleeding is the flushing of excess asphalt cement to the surface of the pavement, as evident in Fig. 3.32. Asphalt cement concrete mixtures are more prone to

|

|

|

FIGURE 3.33 Example of small pothole in flexible pavement. |

bleed with hotter pavement surface temperatures. Bleeding is a result of excess asphalt cement in the mix and/or low air voids in the mix.

Potholes. One of the most common problems is the development of a pothole (Fig. 3.33). Potholes are small, localized, but deep pavement failures characterized by a round shape. Potholes are caused by weak and wet subbase and/or subgrade. In freeze-thaw environments, potholes are generally formed during the thaw.

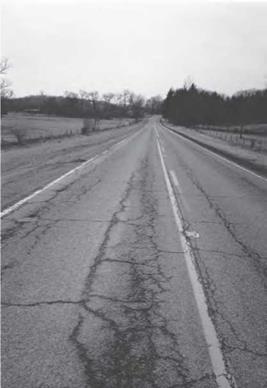

Rutting. Rutting (Fig. 3.34) is the longitudinal deformation of the pavement structure within the wheel tracks. Where found only in the uppermost portions of the pavement, it is caused by poor mixture design and lack of stability. Where rutting is deep-seated and found throughout the depth of the pavement structure, it is caused by inadequate pavement structure above the founding layers or by a weak, wet subgrade.

Corrugation. Corrugations (Fig. 3.35) are transverse waves in the pavement profile, which are found most generally at stop lights, at stop signs, or on hills. Corrugations are found in the wheel track and are the result of acceleration and deceleration of heavy trucks in a regular pattern on the roadway surface. The stability of the asphalt mix can also be a contributing factor.

Longitudinal Cracking. Longitudinal cracking, such as shown in Fig. 3.36, is most often found at paving joints established during construction. The construction joint is most generally specified at lane lines. As weathering of the pavement takes place, the longitudinal joint ravels and eventually spalls. Longitudinal cracks found at locations other than paving joints are due to thermal shrinkage from seasonal temperature changes.

Transverse Cracking. As illustrated by Fig. 3.37, transverse cracking is best described by cracks that form across the pavement perpendicular to the centerline.

|

FIGURE 3.34 Example of rutting in flexible pavement. |

Transverse cracking is caused by thermal shrinkage from seasonal temperature changes and age hardening of the binder.

Block Cracking. Block cracking is the combination of longitudinal and transverse cracking, as shown in Fig. 3.38. As the cracks worsen with time as a result of weathering, they join each other and form block cracking.

|

|

|

FIGURE 3.36 Example of longitudinal cracking in flexible pavement. |

Wheel Track Cracking. Wheel track cracking is shown in Fig. 3.39. It can be described as mostly longitudinal cracks found at the surface of the pavement within a 3-ft-wide (0.9-m) strip considered to be the wheel track. Wheel track cracking ranges from a single longitudinal crack to a series of interconnected longitudinal cracks, also referred to as alligator cracking. Wheel track cracking is commonly considered to be the most alarming distress found in a flexible pavement. This type of cracking starts at the bottom of the pavement structure and is transmitted to the surface. By the time alligator cracking can be detected by visual inspection, the pavement is generally considered to be failed.

|

|

|

FIGURE 3.38 Example of block cracking in flexible pavement. |

|

|

|

FIGURE 3.40 Example of edge cracking in flexible pavement. |

Edge Cracking. Edge cracking, as shown in Fig. 3.40, is a series of short longitudinal or irregular-shaped cracks at the outer 15 in (380 mm) of the pavement. Edge cracking is a result of lack of support outside the pavement edge.

Leave a reply