BRIDGE WIDENING AND REHABILITATION

Shoulders were not always provided on bridges in the past. This in itself can be a reason for widening an existing bridge. More frequently, widening is necessitated by the addition of lanes to the highway, at which time a full shoulder can be provided.

The design and preparation of plans for bridge widening usually require all the same elements as the preparation of the original plans for the structure, plus details and notes for partial removal of the existing bridge, rebar splice details, and notes on sequence of construction and maintenance of traffic. Therefore, it is a mistake to think of such a design project as “just a widening job” when estimating the hours required to design and prepare plans, or when reviewing such estimates for agency approval.

Bridges are generally widened in kind—that is, steel-beam bridges are widened with additional steel beams, prestressed-concrete beam bridges are widened using prestressed-concrete beams, etc. However, beam types different from the original have been used successfully in some widening projects.

|

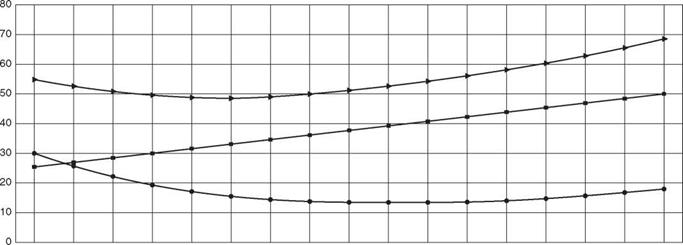

—■— Superstructure cost —•— Substructure cost —►— Total cost

FIGURE 4.11 Example of cost study for optimum span length. Conversions: 1 ft = 0.305 m, 1 sq. ft = 0.0929 m2.

It is sometimes possible to increase the design load capacity of a bridge when widening. If the bridge is steel and was originally designed and constructed noncom – positely, it may be feasible to weld shear studs onto the top flange of the beam or girder if the deck slab must also be replaced. If the deck slab is good, another available technique is to carefully core holes in the slab over the beams, weld shear studs onto the beam flange, and fill the hole with high-strength concrete, thereby making the beam composite. One should always be cognizant of the effect of retrofits on fatigue life, just as one is conscious of the fatigue effect of structural details on new construction.

Another means of increasing load capacity is to space the existing beams closer together. Before this is done, a study should compare the cost of renovation with the cost of replacement with a new superstructure.

Posttensioning of members can also be used to increase the load capacity of existing bridges, or to correct deficiencies in the original design. External posttensioning of prestressed or posttensioned girders has been necessary on some bridges where the design did not adequately anticipate the magnitude of time-dependent deflections that occurred. In one case, a utility bridge developed a sag that trapped rainwater, further increasing the deflection. It was corrected by external posttensioning. Members of truss bridges can be posttensioned to increase the load capacity of the truss. A computer program is available from the BEST Center, University of Maryland, which allows analysis including the effect of posttensioning cables.

When determining the load capacity of an existing bridge, one should refer to the original plans, if available. These plans will generally state the design specifications used and the type and required strength of materials. For steel bridges for which plans are not available but the year of construction is known, the type of steel and the allowable stress may be obtained by reference to the AASHTO Manual for Maintenance Inspection of Bridges. If the bridge is a large or significant one, the type and strength of the steel should be determined by chemical and physical analysis performed on a coupon taken from the bridge. The chemistry, particularly the carbon equivalent, will be important if welding is proposed on the existing steel.

When evaluating the strength of an existing bridge for widening or rehabilitation, reference should be made to AASHTO publications dealing with evaluation and rating for strength and fatigue. Two such publications are the AASHTO Guide Specifications for Fatigue Evaluation of Existing Steel Bridges and the AASHTO Guide Specifications for Strength Evaluation of Existing Steel and Concrete Bridges. Manual for Condition Evaluation of Bridges and Guide Manual for Condition Evaluation and Load and Resistance Factor Rating (LRFR) of Highway Bridges are also available through AASHTO.

Evaluation of an existing prestressed-concrete girder bridge for which plans are not available may be more difficult. The type of girder, whether a standard AASHTO shape or a state standard, may be determined by measurement. The number and size of strands may be apparent at an exposed end, but whether any strands are deflected or debonded, whether the strands are stress-relieved or low-relaxation, and what their strength is are not easily determined. Full-scale load-deflection testing may provide some answers, but is very expensive. This illustrates the importance of maintaining and safeguarding the original plans and as-built drawings, and having complete design data on those plans.

Leave a reply