Windows, Doors, Siding, and Exterior Trim

EACH PHASE OF A HOMEBUILDING PROJECT OFFERS A NEW SET OF CHALLENGES

and rewards, but the work that we do in this chapter is especially exciting. The big, stick-framed box we’ve built is about to receive a beautiful skin, with windows and doors added to make it weatherproof. By the time we’ve finished the tasks in this chapter, the house will show oil" its finished exterior appearance. And with the inside protected from the elements, we arc free to take on all the interior work ahead.

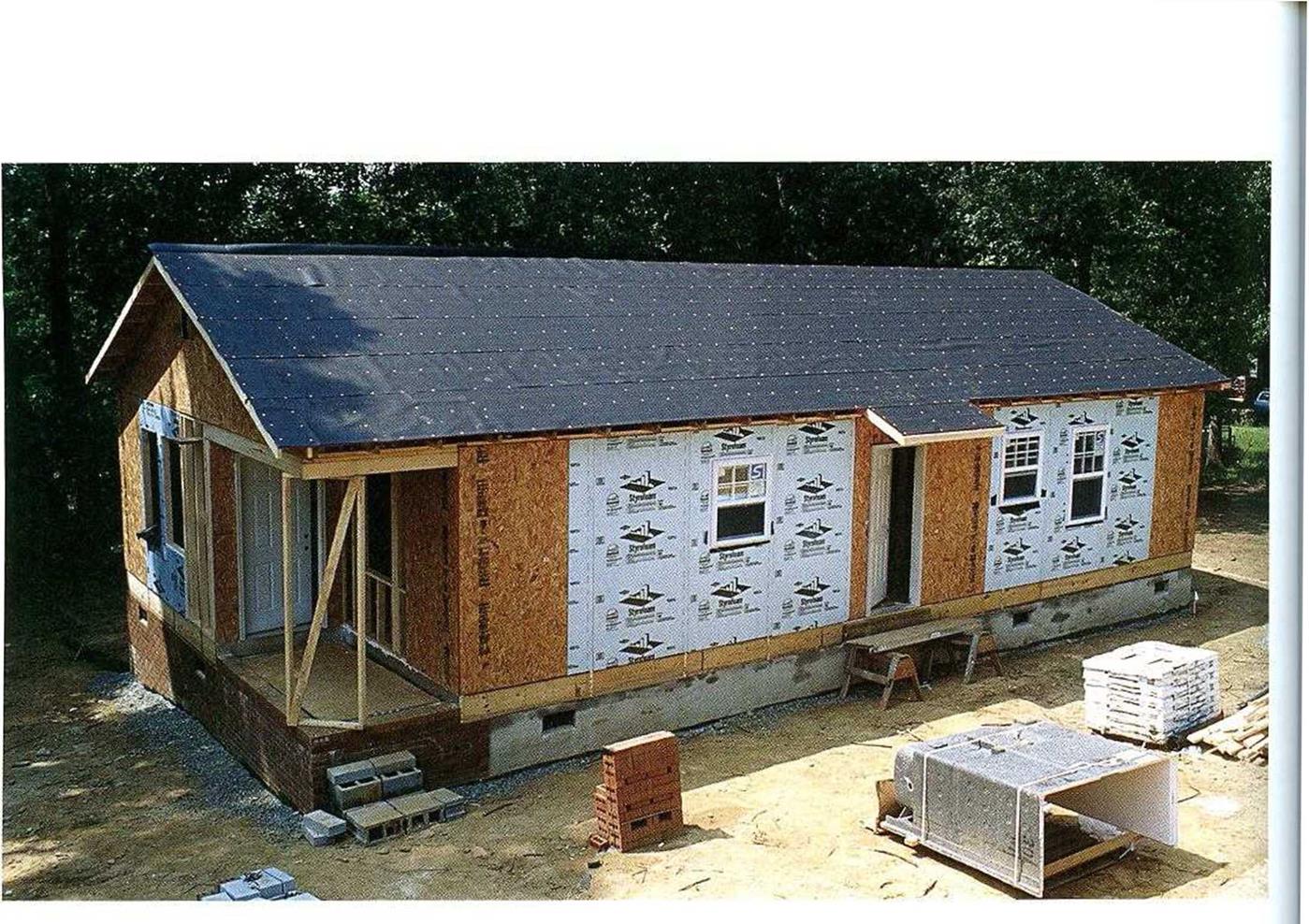

As I mentioned in chapter 4, its common practice in some parts of the country to sheathe wood-framed walls before they are raised rather than after. In other areas, sheathing is eliminated and diagonal steel or wood braces arc installed to nelp walls resist shear forces. Certain types of exterior siding (such as fiber cement) can be nailed directly to the studs and do not require sheathing underneath (see the sidebar on pp. 160-161).

We are sheathing this house with two materials that share the same —in. thick – ness. Structural wood panels (oriented strand board, or OSB) are used in the corners, where they provide necessary shear strength. To cover the framing between the OSB panels, rigid foam insulation board is fastened against the studs and plates.

![]()

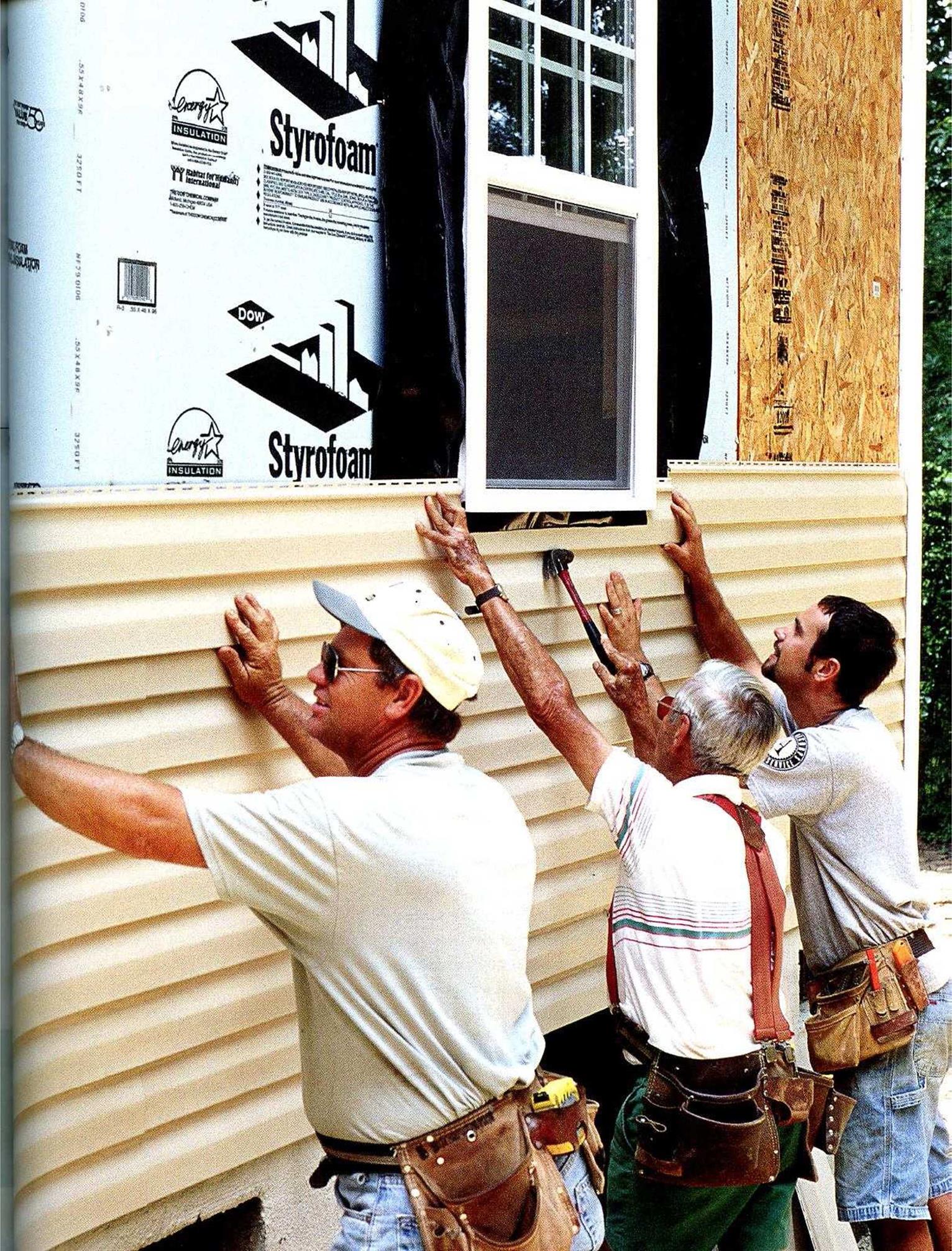

1 Install the Remaining Sheathing and the Rough Exterior Trim

2 Install the Housewrap and Flash Openings

3 Set the Windows and Doors

4 Complete Ventilation and Electrical Work

5 Install the Starter Strips and the Trim for Vinyl Siding

6 Install the Siding Panels

7 Finish the Soffits

8 Cover Exterior Trim with Aluminum Cladding

|

|

|

Lighter and less expensive than wood panels, rigid foam sheets are easy to handle, cut, and install. Their insulating value improves the home’s energy performance, augmenting the R-value of the fiberglass baits installed between the studs.

We won’t make much sawdust in this chapter. Instead, we’ll learn which tools and techniques are needed to install vinyl siding and prefinished aluminum coil stock. This plastic and sheet metal exterior is quite different from the redwood siding and trim I used earlier in my construction career. Depending on your budget, your personal preferences, and the local availability, there are many siding and trim possibilities. Out West, where I’ve done the most building, fiber-cement siding is often used; it has been installed on quite a few Habitat houses in western states. For a c. oser look at this type of siding, see the sidebar on

pp. 160-161. There are other affordable, low – maintenance siding options to consider, too.

A few of them are described briefly on the

і

facing page.

It’s not difficult to understand the popularity of vinyl siding. It’s affordable, widely available, easy to install, and maintenance-free. Vinyl windows, vents, soffit material, and other components are designed to be compatible with vinyl siding, and there are plenty of colors, surface textures, and styles from which to choose. You’ll find vinyl siding on compact, affordable houses like the one featured in this book, as well as on expensive custom-built homes.

Horizontal siding is the most popular type of vinyl siding, and most styles are designed to look like wood clapboards. Clapboard widths

Leave a reply