Try before you buy

So what do you look for when buying a tool? Well, it helps to remember that tools are not like stretch socks, where one size tits all. A circular saw, for example, may have the right

combination of power and weight but still fed out of balance or awkward when vou hold it.

4

A tool that’s not comfortable is like a shoe that is one size too small. It’s never a bargain, regardless of price. A tool that feels good in your hands will most likclv be easvand safe to use. So, whenever possible, try before you buy. Visit home centers and tool dealers that have good selections of tools. Grip the tool to test its balance and feel. If you have small hands, rule out tools that aren’t easv to hold comfort-

4

ably. Try the controls and adjustments, too. Use this hands-on information to make vour

4

selections.

Talk to carpenters, who use tools daily, and ask them for their preferences. Research magazines, such as Fine Homebuilding and the Journal of Light Construction, which evaluate tools. And always buy the best quality you can afford. Most of us know the experience of wishing we had bought quality rather than a piece of junk. Professional tools cost more initially, but they are more durable, more powerful, and easier and safer to use. Ironically, they make it easier to be a beginner.

if you’re intending to work professionally as a carpenter, you’ll eventually acquire quite a large collection of tools. If, however, you’re only planning to build one house or work with Habitat as a weekend volunteer, a small kit of essential tools should stand you in good stead. In addition to the basics described on the following pages, you can acquire more specialized tools as you need then:, which is the best way to do it anyway. Otherwise, you may wind up with unnecessary tools that clutter your tool belt, your storage bucket, and your life. You can also rent specialized tools if you plan to use them just a few times.

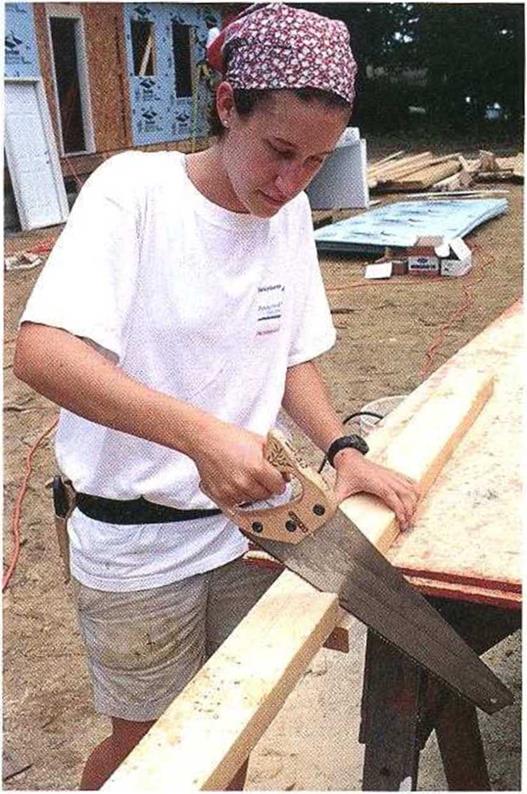

The fundamental tasks of carpentry are measuring, marking, cutting, and joining. And though circular saws and power drill-drivers have largely replaced handsaws, braces, and screwdrivers, many carpentry tasks can still be done with hand tools (see the photo at right). Like power tools, many hand tools have improved over the years.

Just as I sometimes enjoy writing letters on my old manual typewriter, it’s also fun to measure with my old 6-ft. wooden folding rule. Flexible steel tapes have replaced old – fashioned wooden rules, because they’re more compact and capable of measuring much longer distances quickly and accurately. Steel tapes come in many sizes and lengths, but the most common are 16-ft., 25-fit., and 30-ft. models. I prefer a 16-ft. tape, because it feels better in my hand. A 100-ft. tape is useful for checking building lines and squaring foundations. Tape measures have moving parts and receive heavy use, so use the following tips to treat them with special care:

a Don’t leave a tape extended open on the floor, where it could be stepped on and creased. A creased tape will never work properly.

a If a tape is allowed to retract too quickly, the hook can break off when it hits the case. Learn to slow the tape with your fingers as the hook approaches the case.

a Clean any tape that gets gummed with wood pitch, tar, or caulk. A soft rag dampened with mineral spirits works well to remove those materials.

![]()

a When working in wet weather, wipe the tape dry with a cloth before reeling it into the case. Moisture inside the tape case can

a When working in wet weather, wipe the tape dry with a cloth before reeling it into the case. Moisture inside the tape case can

Leave a reply