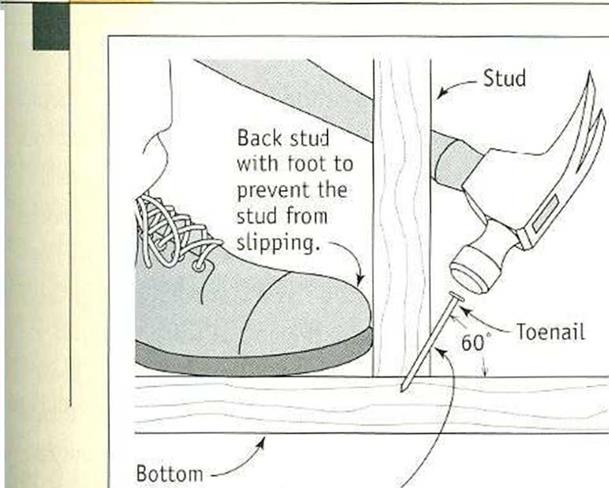

Techniques TOENAILING BASICS

DRIVING A COUPLE of nails through the side of one 2x into the edge or face of another creates a strong connection. This is a good way to join two 2xs at a right angle. But sometimes this isn’t possible, either because the board is too thick or because its face is not exposed. That’s when you resort to driving a nail at an angle, or toenailing.

DRIVING A COUPLE of nails through the side of one 2x into the edge or face of another creates a strong connection. This is a good way to join two 2xs at a right angle. But sometimes this isn’t possible, either because the board is too thick or because its face is not exposed. That’s when you resort to driving a nail at an angle, or toenailing.

To toenail two boards together, hold the nail at a 60-degree angle and start it about 1 in. from the end of the board. If the nail angle is not correct, the connection between the two pieces of wood will not be as strong. Back up the wood with your foot to hold the board in place as you toenail. With practice, you’ll soon gain skill, speed, and confidence.

|

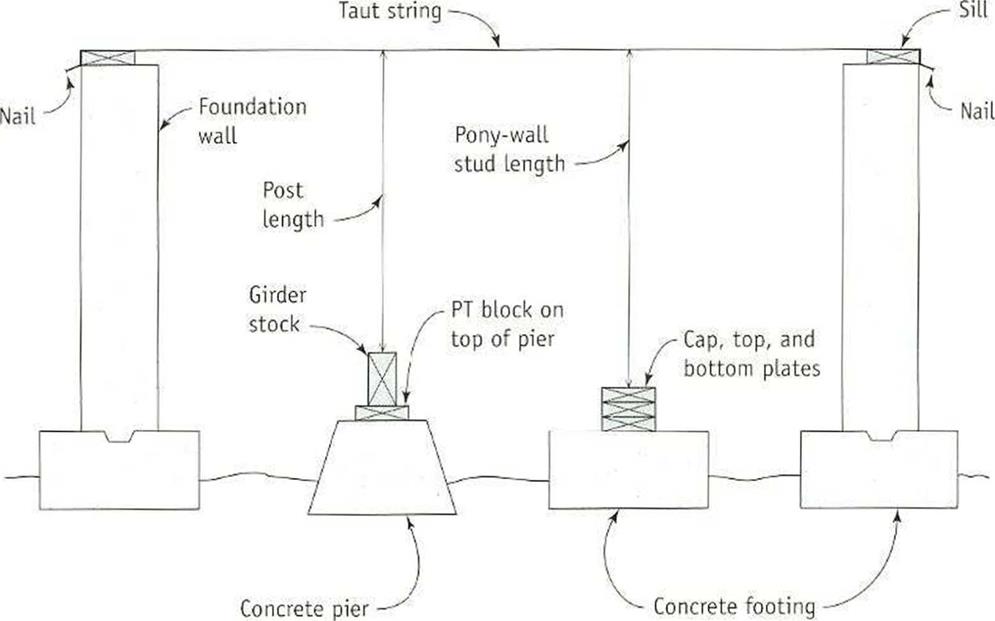

MEASURING POST OR PONY-WALL STUD LENGTHS |

|

walls stticis, stretching a line above a piece of girder stock placed on the pier. Cut youi posts to length, then secure them directly to the piers or toenail them to the blocks attached to the piers. Make sure the posts arc plumb and parallel to one another.

Girders must butt together over a post. When the end of a girder fits into a pocket in the foundation, you’ll have to shim up the girder to get the top surface level with the top of the sill. The shims used beneath girders will hear the full weight of the floor, so they must he cut carefully from pressure-treated stock. Cut uniformly thick shims instead of tapered ones and make them large enough to fit in

the bottom of the foundation pocket. Because of concretes ability to absorb moisture, code requires that the end of the girder he held about V: in. away from the hack of the pocket when cutting the girder to 111. If you’re not using pressure-treated stock for the girder, you can wrap the end of the girder with builder’s felt or sheet metal to give it some protection against moisture damage. Toenail the girders to the posts with either four 8d or three 16d nails. Now brace the posts and splice the girders by nailing the plywood gussets on both sides of the joint (see the illustration on p. 44).

Leave a reply