Techniques FITTING SHEATHING

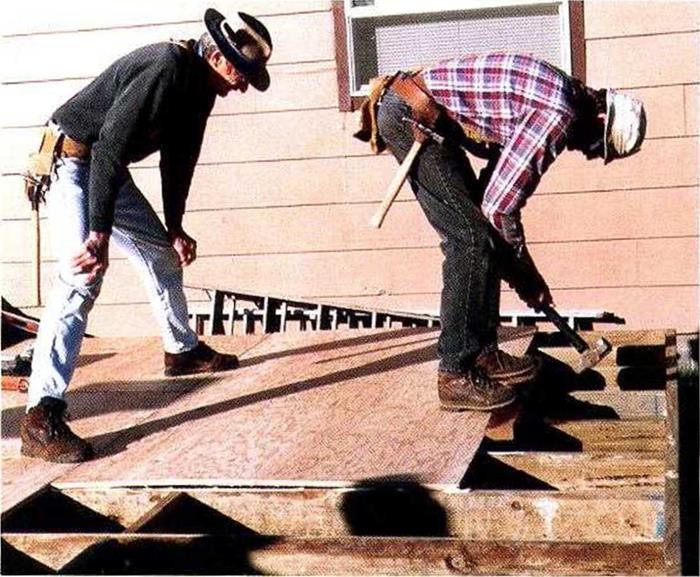

SOMETIMES A LITTLE extra persuasion is needed to unite tongue-and-groove sheathing panels. Have one person stand on the edge of the sheet and hold it flat and snug against the previous row of sheathing. Another person can lay a scrap of 2x (to protect the groove from damage) against the sheet and hit it with a sledgehammer. A couple of licks should bring the two sheets together. If not, check the edge for damage or for an obstruction that may be holding the two sheets apart.

COAX PANELS INTO PLACE. A couple of good wallops with a sledge will usually seat even an ornery Sheet Of tongue-and-grOOVe Sheathing. [Photo by Roe л. Osborn, courtesy Fine Homebuilding magazine, The Taunton Press, Inc.]

COAX PANELS INTO PLACE. A couple of good wallops with a sledge will usually seat even an ornery Sheet Of tongue-and-grOOVe Sheathing. [Photo by Roe л. Osborn, courtesy Fine Homebuilding magazine, The Taunton Press, Inc.]

line. On one side of the building, measure in 48УІ in. at each end and snap a chalkline across the joists. The first row of sheathing is laid and nailed directly on that line. Getting this first row straight makes it easier to lav all sub-

O і

sequent rows.

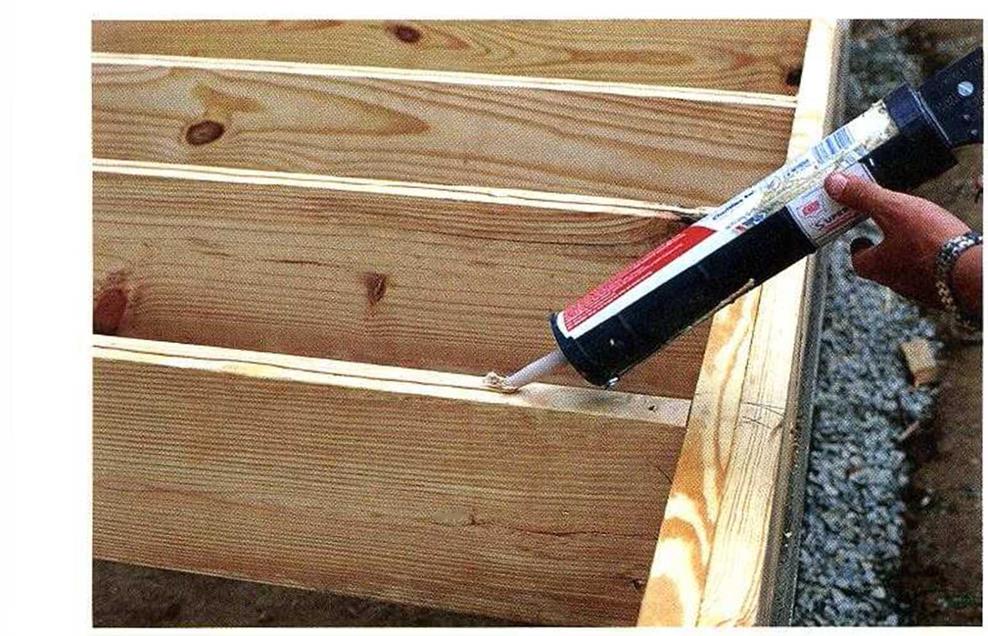

![]() Lay down a full К-in. bead of construction adhesive on the joists beneath each sheet just before setting it in place (see the photo at left). This makes the floor structurally stronger and cuts down on squeaks in the future. Lay the first sheet with its grooved edge right along the control line, with one end on the center

Lay down a full К-in. bead of construction adhesive on the joists beneath each sheet just before setting it in place (see the photo at left). This makes the floor structurally stronger and cuts down on squeaks in the future. Lay the first sheet with its grooved edge right along the control line, with one end on the center

|

ofa rim joist and the other end landing mid-joist—8 ft. to the left or the right. If a sheet doesn’t fall on the center ofa joist, try pushing the joist over a bit. If this can’t be done, mark the sheet to length so the edge will land mid-joist, then snap a chalkline and cut the sheet. Finish sheathing the first row before moving on to the second one.

The second row of sheathing is installed much like the first, except that you begin with half a sheet (a 4-ft. by 4-ft. piece). This staggers the joints, which makes for a stronger floor. If you re building in a humid climate, leave about % in. between the ends and the edges of the sheets to allow for expansion.

This gap can be gauged by eye or by using an 8d nail as a spacer. The 14-in. gap between sheets means that vou will have to trim an end now and then so that each sheet lands squarely on a joist. Some manufacturers make sheets % in. short to allow for gaps and eliminate the need to cut sheets.

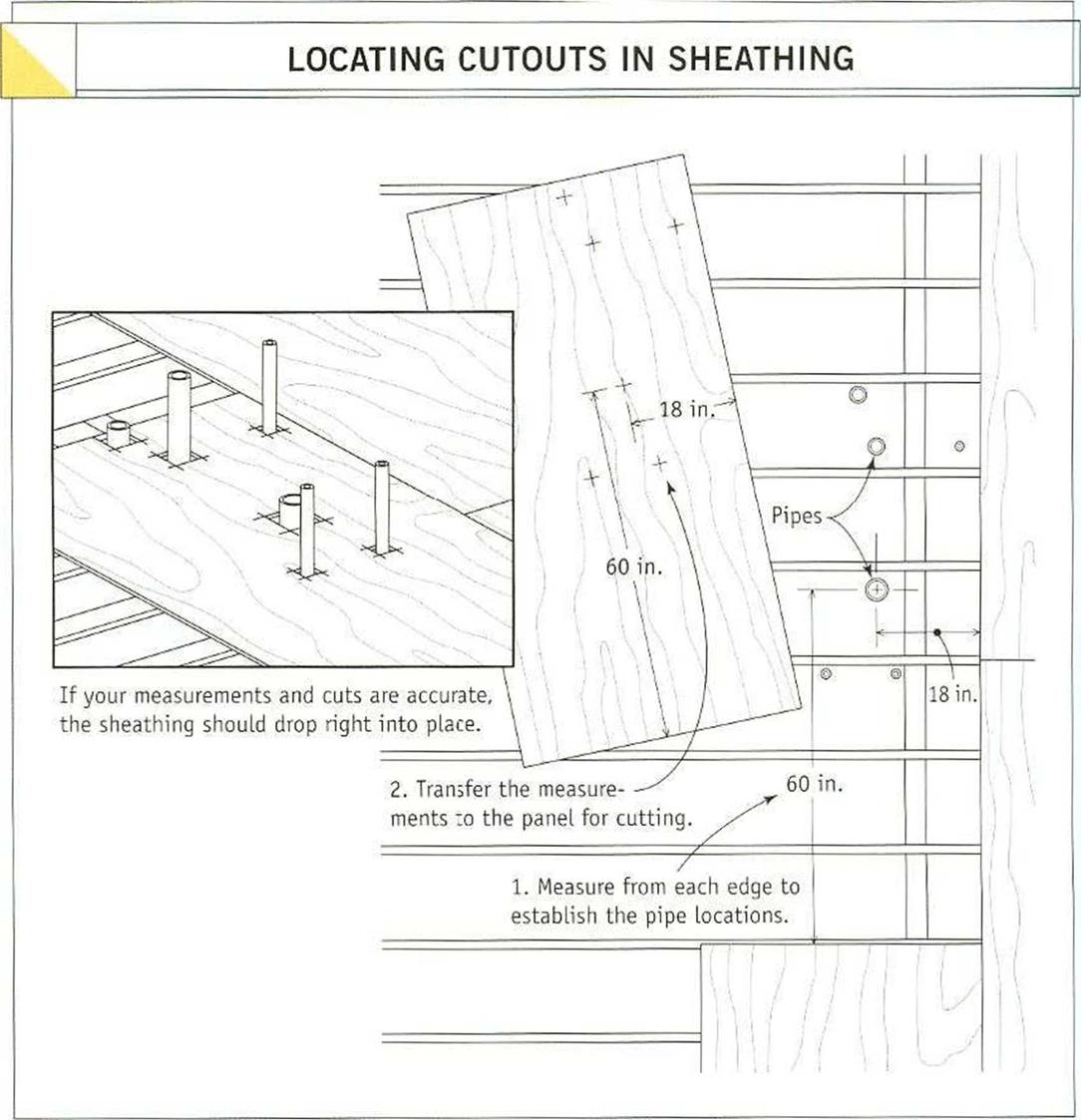

When plumbing pipes are installed before the sheathing, vou must lav out and cut holes in the sheathing. The easiest wav 😮 lav out these cuts is to measure from the edges of sheathing already in place to the center of the pipe, then transfer those measurements to the sheet that the pipe will go through (see the illustration on the facing page). Cut the holes somewhat larger than the pipes, using a circular saw to make a plunge cut, as shown in chapter 2. This makes it easier to lift the sheet and set it in place over the pipes. Later, seal the holes well to keep cold or moist air from entering the living space from below.

Secure the sheathing to the joists with 8d nails

When the last panel in a course of sheathing extends beyond the rim joist, cut it flush with

the rim joist before nailing it down (see the photo above). The typical railing schedule for sheathing is 8d nails 6 in. o. c. around the perimeter of the building and at joints between the sheets and 12 in. o. c. in the field (the middle of the sheets). It’s best to nail the sheets soon after laying them, especially in hot weather, so that the adhesive doesn’t have a chance to set before the sheet is pulled fast to the joists. If necessary, snap chalklines across the panels to show the joist locations for nailing.

An efficient method is to have one team lav

4

sheets and tack them at their four corners, then have another team follow behind, nailing off the sheets completely. In many areas of the country carpenters use rough-coated, hot- dipped galvanized nails or nails with grooves cut in them (ring-shank nails) to ensure that the sheathing stays firmly secured to the joists.

|

Walls Create Sp |

Leave a reply