STEP5 Build Midspan Support for Joists

Unless you arc building on a slab, yoiTlI probably need to provide midspan support for the floor joists. Without additional support somewhere between the sills, the joists can be overspanned, resulting in a finished floor that sags

or feels bouncv. A friend once :ook me

/

through his 18th-century home in rural Connecticut. The beautiful, hand-hewn floor joists in the basement were fascinating—dry, free from rot and termites—but far overspanned. Upstairs, it felt like walking on ocean waves. Clearly, what was needed was some support to keep the joists from sagging and bouncing in the middle.

Codes req u і re a m і n і m u m оf 18 in. between the earth and the joists in a crawl space. These days, two systems. ire commonly used to provide midspan support for the joists: crib walls (also called pony walls) and post-and-girder systems. A crib wall is just a shortened version of a regular stud wall and is supported along a continuous concrete fooling. With a post-and-girder system, a solid or built-up girder (also called a beam) is sup

ported by posts every 6 ft. or so, depending on code. The girder usually fits into a recess or pocket where it meets the foundation wall, loined to the girder by metal connectors or plywood gussets, the posts bear on concrete piers (see the illustration on p. 44).

In both these systems, the joists rest on and are nailed to the top support member. The width of the joists and the length of the span determine how much support is needed. With 2×6 joists, for example, posts and girders are often placed every 6 ft. With 2x12s or engineered 1-joists, only one support in the center may be needed.

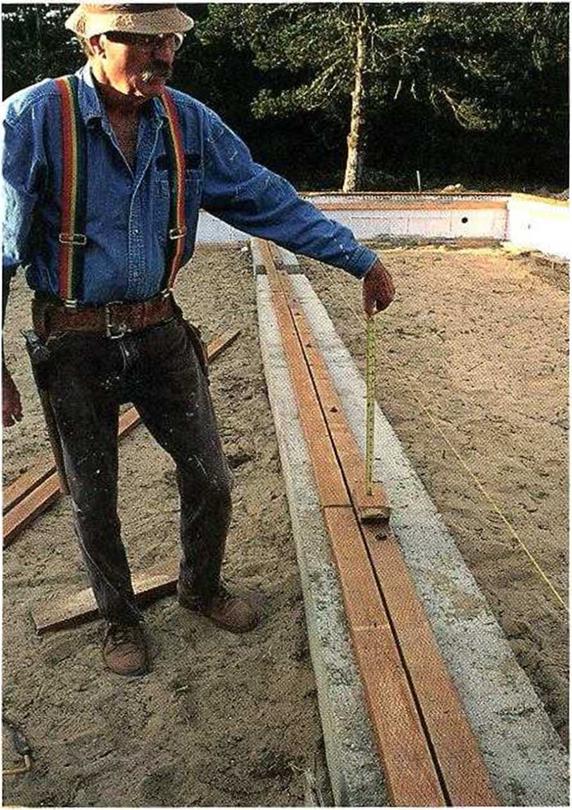

lust in case a moisture or termite problem develops in the future, I like to build crib walls with pressure-treated wood. To determine the length of the crib walls s. uds, first bolt the walls bottom plate to the footing. Then tightly stretch a string above the crib walls bottom plate and across the mudsills installed on the stem walls. Set two pieces of top plate stock on the bottom plate. The distance between the top plate stock and the string is the length of the crib wall’s studs (see the lop left photo on p. 60).

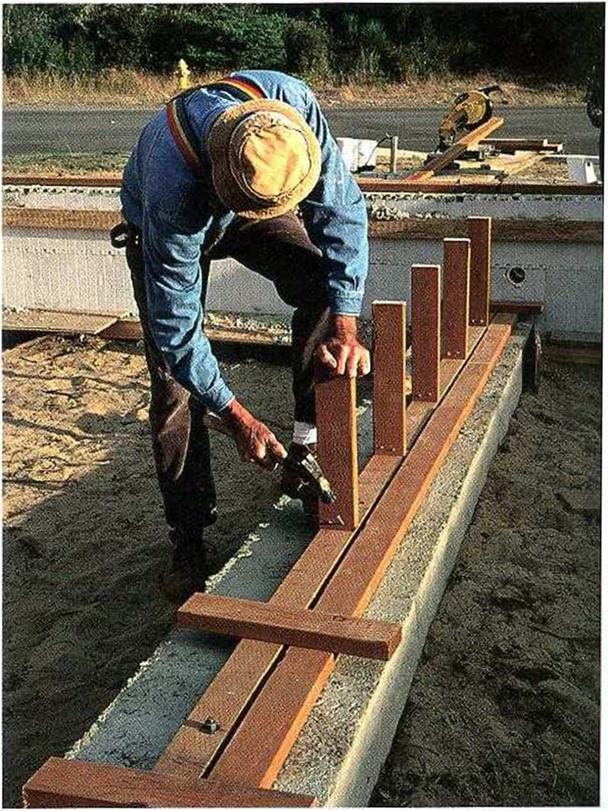

BUILD A CRIB WALL. Also referred to as a pony wall, a crib wall—a short, stud-framed wall—is one way to provide midspan support for joists that extend over a crawl space. After bolting the wall’s bottom plate to the footing, stretch a line over the sills to measure the length of the crib

wall’s studs (see the left photo above). Place two pieces of top plate stock on the wall’s bottom plate and measure up to the line. Toenail the studs to the bottom plate, spacing them 16 in. O. C. (see the right photo above). [Photos Memo Jasso.]

FINISHING THE WALL. After nailing both top plates, fasten plywood or OSB sheathing to one side to give the wall shear strength. Hold the bottom edge of sheathing panels V? in. off the Concrete. [Photo Memo Jasso.]

Toenail the studs to the bottom plate, spacing them 24 in. o. c. but leaving a 30-in.-wide opening somewhere in the wall so that plumbers, electricians, and others can got from one side of the crawl space to the other. When toenailing the studs to the crib wall’s bottom plate, you can drive either four 8d toenails or three 16d nails per stud. If you’re using a pneumatic nailer, make sure von follow the safety guidelines explained on p. 63.

Once the crib wall’s studs are in place, nail on the two top plates. Drive a pair of 16d nails through the first plate into the top of each stud. Secure the double top plate with a single 16d nail at each stud location, and toenail the plate’s ends to the sill on the foundation wall at each end of the house. 1 like to sheathe one side of a crib wall with pressure-treated plywood (my first choice) or OSB to provide

good lateral bracing (see the bottom photo on the facing page). Be sure not to sheathe over the opening you framed in the wall. As an alternative to sheathing a crib wall, you can stiffen it with 2x diagonal braces nailed to the top and the bottom plates and across at least one stud.

Build a post-and-girder system

If you’re using pressure-treated posts to construct a post-and-girder system, the base of the post can be anchored directly to the top of its concrete pier. Most piers these days are precast units that come with metal straps to anchor wood posts or pads to the lop. Secure a 11 in.-thick pressure-treated pad to the lop of the pier if the posts will be cut from untreated lumber. You can measure for the post’s length just as you measured for the crib

Leave a reply