Safely on the Job USING DRILLS

OLD DRILLS WERE MADE with enclosed trigger guards like those on firearms. Carpenters sometimes had their trigger fingers caught and broken from time to time, such as when a drill bit got hung up on a knot in a board and spun suddenly. For safety reasons, workers often used a hacksaw to cut out the trigger guards. These days, manufacturers have eliminated trigger guards, but that doesn’t mean drills can’t do you harm. To use a drill safely, follow these guidelines:

^ Use clean, sharp bits.

a Don’t force the drill; let it cut at its own pace.

a Use a slower speed when drilling harder materials, and coat the bit with wax or silicone to reduce resistance.

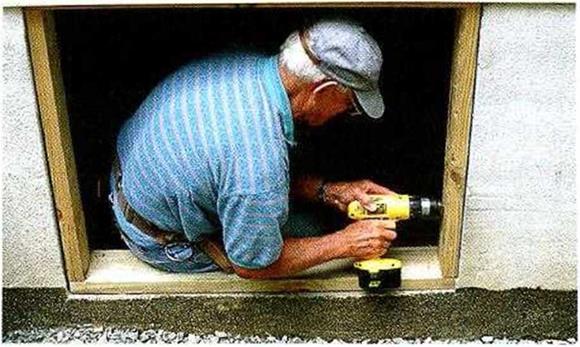

a When drilling thick material, hold the drill with both hands, and Lse the side handle if the drill comes with one.

|

|

a If you’re drilling a deep hole, pull the bit out of the hole from time to time to clear debris from the bit and the hole.

a Don’t rely on hand pressure alone to hold the workpiece in which you’re drilling. Instead, clamp the workpiece to a sawhorse or a workbench.

a Be especially careful when drilling from a ladder. Make sure you have proper balance.

a Release the trigger immediately if the bit begins to bind or catch.

![]()

chuck (bit holder). A %-in. model can handle a bit shank diameter ot up to % in. For general carpentry work, buy either a %-in. or a k?-in. drill. Look for a model with a reverse switch (so you can remove screws) and variable speed control. A good cordless drill will also have a clutch, which makes it easier to drive screws of different sizes. A low clutch setting (1 to 3) is good for driving small screws. Higher sellings are used for bigger screws.

Power tools need adequate power to operate properly, and that means you need good – quality extension cords. The smaller the gauge number marked on the cord, the heavier the wire. The three most common gauges are 12, 14, and 16 (12 is the heaviest). From time to time, I’ve seen carpenters run a circular saw with a 100-ft. ]6-gauge extension cord. That’s like watering a lawn with a hose the diameter of a drinking straw. Not much water

(or, in the case of an extension cord, electricity) comes through. With a light extension cord, you risk burning out the motor. To prevent that, always use the shortest cord that

4

will do the job. There’s no need to use a 50-ft. cord if you are working just 15 ft. from an outlet. Here’s a rule you can use for selecting the proper extension cord: Use 16-gauge wire for a 25-ft. (or shorter) cord, 14-gauge wire for a 50-ft. cord, and 12-gauge wire for a 100-ft. cord.

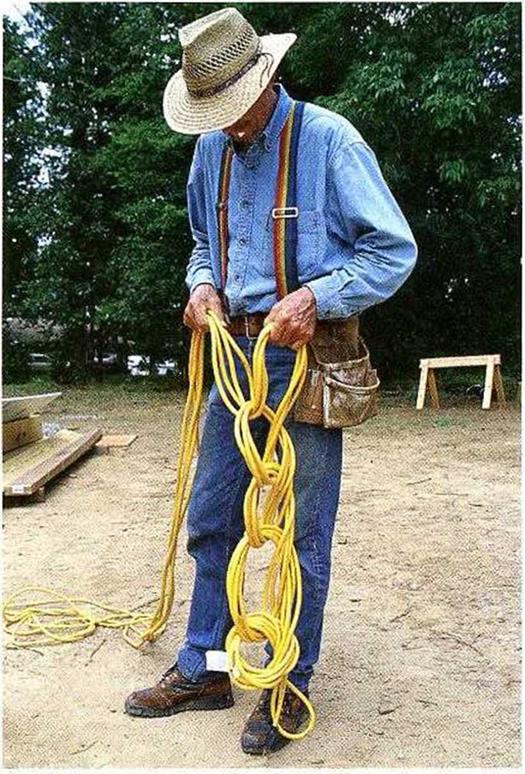

Proper care of cords is essential. Looping a cord into a daisy chain, or a simple crochet stitch, makes for easy storage (see. he photo below). If a cord is frayed or nicked, i cpaii it. A cord with exposed wires can be extremely dangerous. If that happens, the cord should he cut and rewired with new plugs. You can buy – cords equipped with a built-in ground-fault circuit interrupter (GFCl). In the event of a short, the GFCI automatically shu. s off power, preventing electrical shock.

![]()

Leave a reply