Materials SIZES AND TYPES OF DRYWALL

DRYWALL IS MADE by sandwiching a gypsum core between two sheets of paper. The "good" side of the panel is faced with smooth, white paper that takes paint easily. The "bad" side is darker in color, with a rough, porous paper surface. Panels (also called sheets) of drywall are packaged in pairs; to open the package, simply pull off the strips of paper that extend along each end.

The standard width for drywall panels is 48 in. Different lengths are available but, for affordable housing, the most commonly used lengths are 8 ft. and 12 ft. The most common thickness for drywall is Уг in. However, Ye-in.-thick panels are often used on ceilings where the joists are spaced 2 ft. o. c. because they are less prone to sagging. Most codes require Ys-in. panels between the garage and the house for fire resistance. If you

use Vs-in. drywall on the walls, be sure to order wider doorjambs.

Water-resistant drywall is often used in high – moisture areas, such as bathrooms. Called "green – board" because of its green-paper facing, it is treated to resist moisture damage but is not waterproof. It’s most often used to cover wall areas above tub and shower enclosures. Greenboard can be taped and painted just like regular drywall. It should not be installed on the ceiling, unless the joists are spaced 12 in. o. c. to keep the board from sagging.

The short (48-in.) ends of a drywall panel are cut square, leaving the gypsum core exposed. The long edges of the panel are faced with paper and tapered so that the seams between panels can be leveled with the surrounding drywall during the finishing process.

|

PREPARING FOR DRYWALL INSTALLATION |

|

warm weather. Otherwise, make sure the wood dries out. You can even run a dehumidifier inside, if necessary.

Take time to clean up any scraps of wood or trash on the floor. Once the floor is clean, use a piece of keel (I use red because it shows up well) to mark the stud, trimmer, and cripple locations on the floor and the joist locations on the top plate. Knowing the location of studs and joists makes it easier to nail off dry – wall and, later, baseboard trim.

It’s also a good idea to mark the locations of electrical outlets on the floor (see the top illustration at right). This helps avoid installing drywall panels over outlets, which can easily happen if you’re not paying attention. If it does happen anyway, at least there will be a mark on the floor telling you where the outlet is located. You can also mark the location of the backing placed in the walls to support towel racks, grab bars, toilet-paper holders, and so on.

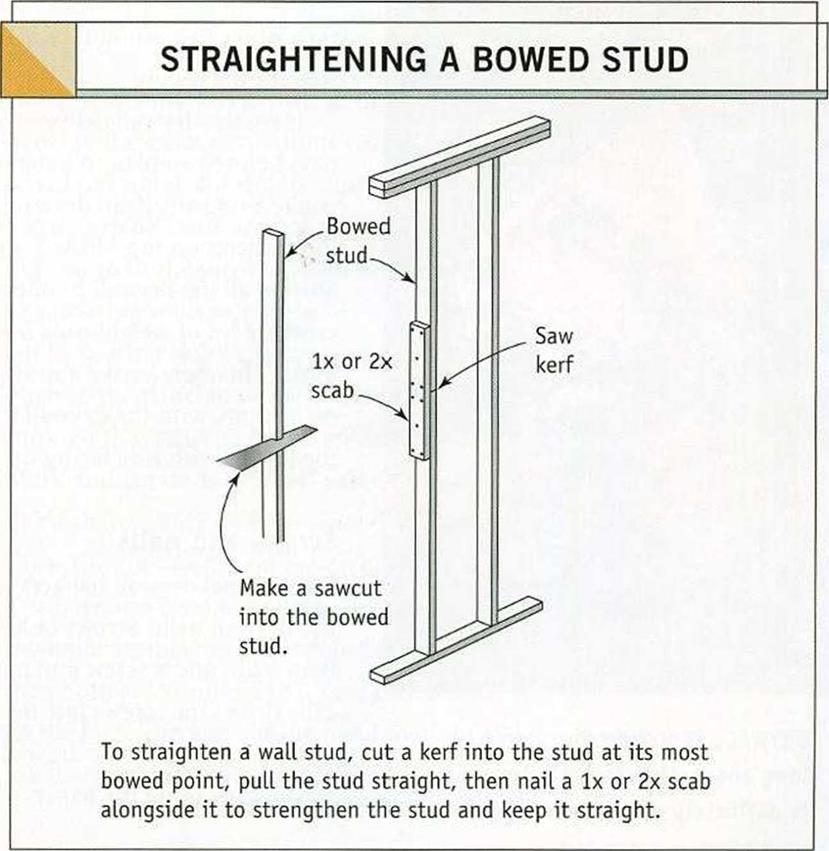

Even if all the studs were crowned in one direction during wall framing, it doesn’t ensure a perfectly straight wall. Sight down the length of the walls or lay a straightedge across them to locate bad studs. Replace any badly bowed studs, or fix a bowed stud by making a cut into the bowed area, forcing the stud straight, and bracing it with a lx cleat (see the bottom illustration at right).

The tools you need to install drywall are pretty basic. In addition to the chalkline and tape measure you’ve used for the work covered in earlier chapters, you’ll need the following tools:

Leave a reply