Materials HOW TO ORDER VINYL SIDING

HORIZONTAL SIDING PANELS are usually 12 ft.

6 in. long, though some companies make longer panels. Siding is sold by the square, or the number of panels needed to cover 100 sq. ft. To estimate how many squares of siding you’ll need, calculate how many square feet of wall surface you need to cover, add 10% for waste, then divide by 100.

Order enough starter strips to go around the entire building; these typically come in 10-ft. lengths. You’ll also need trim for each inside and outside corner. You can order trim pieces that are the same color as the siding or use a contrasting color, as we did on this house.

If the windows didn’t come with an integral J-channel, or channel surround, then order enough

J-channel to cover the top and the sides of all the windows and doors. J-channel is also used along the rake and soffit, as shown on p. 169. You also need to order enough undersill trim to go be. ow each window and to cap the top edge of the last piece of wall siding on the eave walls, which is how they are often finished.

Large-head, ГЛ-іп. to 2-in. galvanized nails are used to attach both the siding and the trim.

A 50-lb. box should be adequate for a small house. Tinally, don’t forget about the vinyl soffit panels for closing in the area under the eaves. As shown in the following pages, soffit panels may require J – or F-channel trim.

STEP 1 Install the Remaining Sheathing and the Rough Exterior Trim

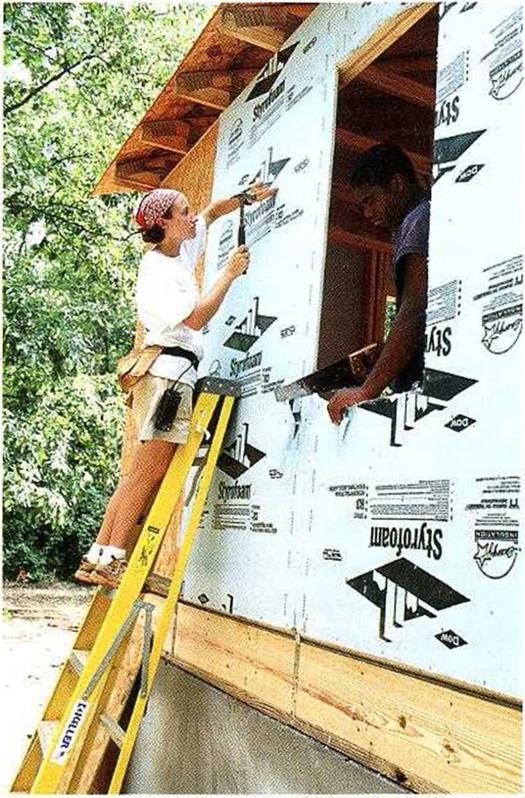

Straight courses of finish siding and sharplooking exterior trim depend on good prep work on the sheathing and exterior trim surfaces that will be covered with aluminum cladding. A good deal of wall sheathing will already be done at this stage. Now that finish siding is about to be installed, it’s important to make sure the wall surfaces are flat and free of gaps that will cause dips or irregularities when the vinyl is installed. When installing foam sheathing, you can sheathe right over window and door openings, then use a handsaw to cut out the foam from the opening (see the photo at left).

If necessary, install wood sheathing or foam board over any unsheathed areas on

which siding will be installed. These areas include the rim joist and headers above windows and doors. Along eave walls, its also essential to extend the sheathing between the roof trusses above the top plate of the exterior wall, as shown in the photo at right. This additional sheathing acts as a baffle, preventing attic insulation from spilling out into the eaves. Cut each OSB panel so that there are a couple of inches of open space between the top edge of the panel and the top edge of the roof trusses. This clearance is essential for good ventilation; it allows air to be drawn through the soffit vents and into the attic space.

which siding will be installed. These areas include the rim joist and headers above windows and doors. Along eave walls, its also essential to extend the sheathing between the roof trusses above the top plate of the exterior wall, as shown in the photo at right. This additional sheathing acts as a baffle, preventing attic insulation from spilling out into the eaves. Cut each OSB panel so that there are a couple of inches of open space between the top edge of the panel and the top edge of the roof trusses. This clearance is essential for good ventilation; it allows air to be drawn through the soffit vents and into the attic space.

Safety on the lob SAFE SCAFFOLDING KEEPS YOU OUT OF HARM’S WAY

ON SINGLE-STORY CONSTRUCTION, most scaffold work can be done with good sawhorses and good planks. Make sure the planks you choose have a solid, even grain and small, tight knots.

If a plank breaks, a fall of only a couple of feet can put you out of commission for a while. And just because you buy good scaffold planks today doesn’t mean that they will be safe to use a year from now, especially if they’re left out in the elements. I prefer to use manufactured decking planks made of steel and aluminum. They are more expensive, but they make a more secure working platform.

When you have to work higher up, you’re better off buying or renting solid-pipe scaffolding. These 6-ft.-high units are easy to set up, and they create a 5-ft. by 8-ft. working platform. Make sure the legs are set on a firm foundation and not just on bare earth. Pipe-scaffolding units can be stacked on top of each other for working on a two-story building. If you will be working more than 10 ft.

high, ask for guardrails, which are easy to install and help protect you from an accidental fall.

Some builders like to use pump jacks and ladder jacks as an alternative to pipe scaffolding. Available at most supply houses, these jacks are useful when installing sheathing, housewrap, or siding. Used in pairs, pump jacks attach to double 2×4 or single 4×4 (372-in.) posts that are held upright with braces temporarily nailed to the roof or to the wall framing. Each pump jack can move up and down on its post to adjust the elevation of the work platform.

If you’re using pump jacks, make sure the units come with a built-in guardrail that protects you from falling backward. Make sure the uprights rest on a solid base and not on bare earth.

Ladder jacks are steel brackets that hook on the rungs of ladders. Once the brackets are secured to a pair of ladders, you can set planks on the brackets. If you want to move up and work at a higher level, you must remove the planks and reposition the brackets.

Leave a reply