Interior Trim, Cabinets, Countertops, and Clost

WHEN ГМ FEELING NOSTALGIC, I think about the fancy, vvell-crafted toolkit I carried

from job to job before 1 switched to a 5-gal. plastic bucket. That kit had a place for all my finish tools—handsaws, levels, small hammers, razor-sharp chisels with their blades wrapped in soft cotton, and planes that left long curls of wood with each pass. My brother, Jim, still has his shiny, metal miter box with its long backsaw—that’s what we used to make perfect cuts in trim before chopsaws came along. Back in the late 40s and early ’50s, those were the tools that master builders passed down to us “kids" as they taught us the craft.

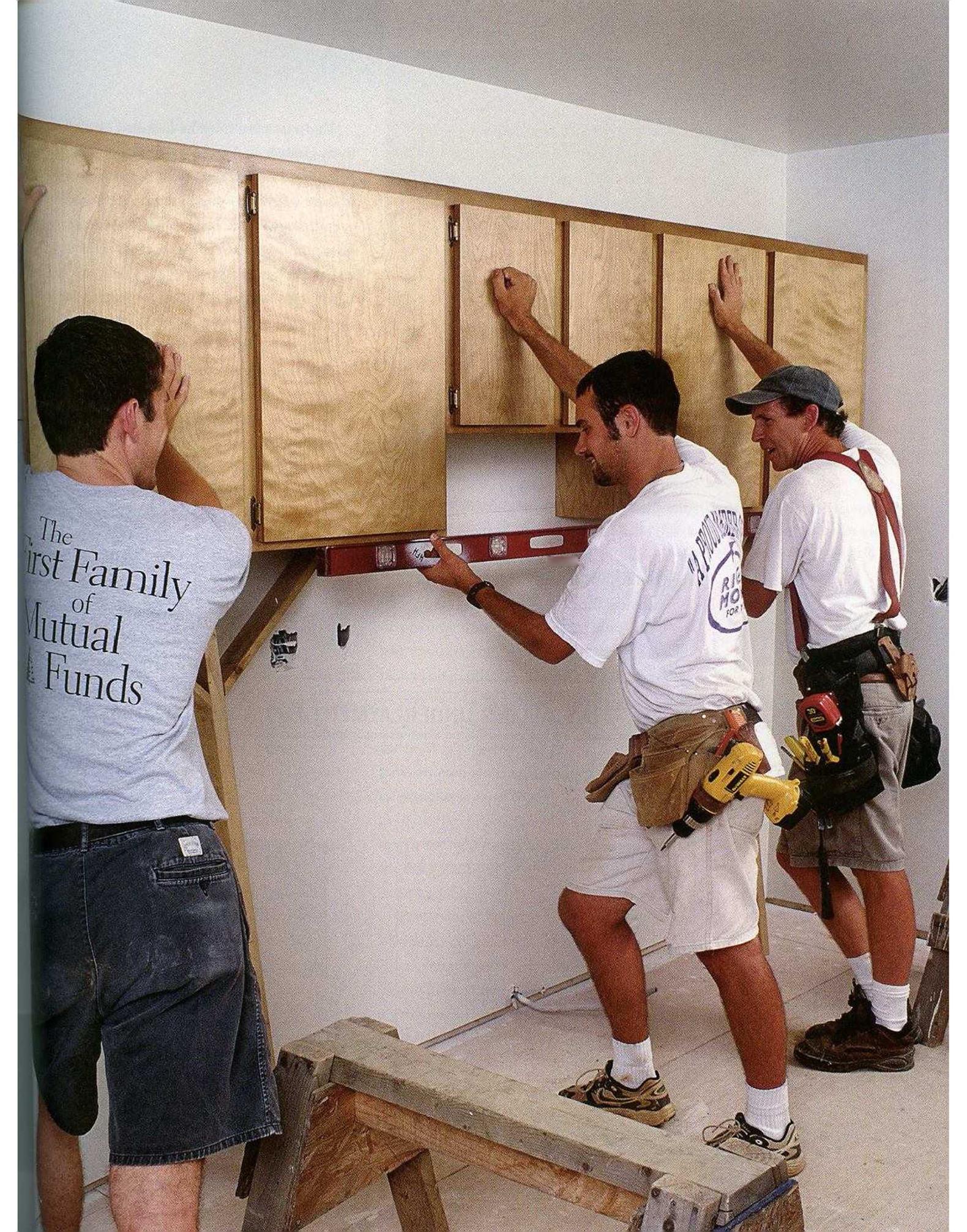

Today, carpentry is different. Power tools dominate—from motorized miter saws (chopsaws) and pneumatic nailers to cordless drills, belt sanders, random-orbit sanders, and jigsaws. And many of the things we used to build at the job site, such as kitchen cabinets, bathroom vanities, and door and window jambs, are now factory – made products that arrive ready to install. Despite these changes, basic hand-tool and careful layout skills are still essential, especially at this stage of the game, when the rough frame of the house, with all its imperfections, has been covered by drywall, and the walls have been painted. Now it’s time to prepare floors for vinyl and carpet;

![]()

![]()

Install Underlayment for Vinyl Flooring Install the Interior Doors Install the Window and Door Casings Install the Cabinets

5 Install the Countertops

6 Install the Baseboard and Chair Rail

7 Trim Out the Closets

install interior doors, window casing, and interior trim; and secure cabinets and counter – tops. Do this work right, and the inside of your house will begin to look beautiful and much more livable.

STEP 1 Install Underlayment for Vinyl Flooring

Because vinyl flooring is quite thin, it is common to install sheets of underlayment over a subfloor to provide a smooth, level base for the vinyl. Typically just M in. thick, 4×8 underlayment sheets can be made of particleboard (wood particles glued together under pressure), MDF (medium-density fiberboard, a smoother version of particleboard), or plywood. Ї like to install underlayment in the kitchen and bathroom after the drywall is finished but before the cabinets or prehung doors are installed.

Underlayment must be installed on a relatively clean floor. Remove all globs of joint compound from the subfloor throughout the house and give it a good vacuuming. I prefer vacuuming (with a rugged, wet-dry vac, not a home model) to sweeping, because sweeping can create a dust storm. Some builders apply beads of construction adhesive before installing underlayment. A clean floor allows you to do this. Adhesive won’t adhere to a dirty floor.

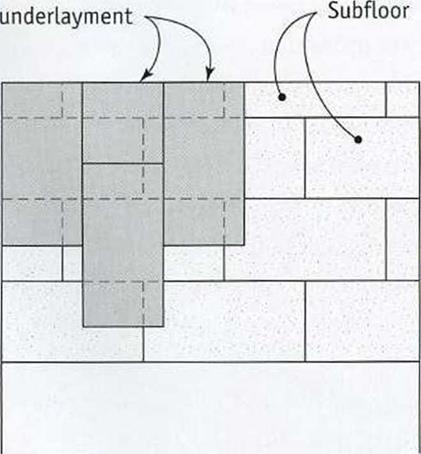

Sheets of underlayment go down just like the subfloor. Lay them so the joints don’t break on the subfloor joints underneath (see the illustration below). When you have to cut a panel to length, lay the cut end against the wall with the factory edges in the middle of the room. This will ensure a tight fit between sheets.

The best way to secure underlayment to the subfloor is with a pneumatic or heavy-duty electric stapler. Drive one staple every 4 in. along the edges of each sheet and 4 in. o. c. in

|

|

|

|

|

|

|

|

|

|

|

|

![]()

both directions in the field. If necessary, snap chalklines to make a grid of 4-in. squares. A lot of staples are needed to make sure the underlayment doesn’t bubble should it absorb moisture from the vinyl adhesive or other sources.

If you’re nailing by hand, drive iM-in. ring – shank nails in the same pattern as described above. The problem with nails is that they must be driven exactly flush with the surface of the underlayment. If they are left proud (protruding above the surface), then you’ll be able to see them through the thin vinyl flooring. If they’re driven below the surface, they can be covered and hidden with a leveling compound—but that means more work.

After nailing the underlayment in the bathroom, fill the joint between the panel and the bathtub with silicone caulk. This helps prevent water from entering at that junction.

Leave a reply