Framing Lumber

Lumber is sized in “nominal," as opposed to number. For example, a piece of lumber that actually

|

Actual dimensions 1 3W" 1 Nominal 2 x 4 dimensions |

|

Actual %" 1 3W" 1 Nominal 1 x 4 |

|

|

“actual," dimensions. A nominal dimension rounds measures 1%”x 3%" is rounded off to the nominal off the actual dimension to the next highest whole 2” x 4”.

|

GWB = Gypsum wallboard (also called drywall or sheetrock). The most common thicknesses are V21 and 5/8". |

![]()

![]()

|

|

|

|

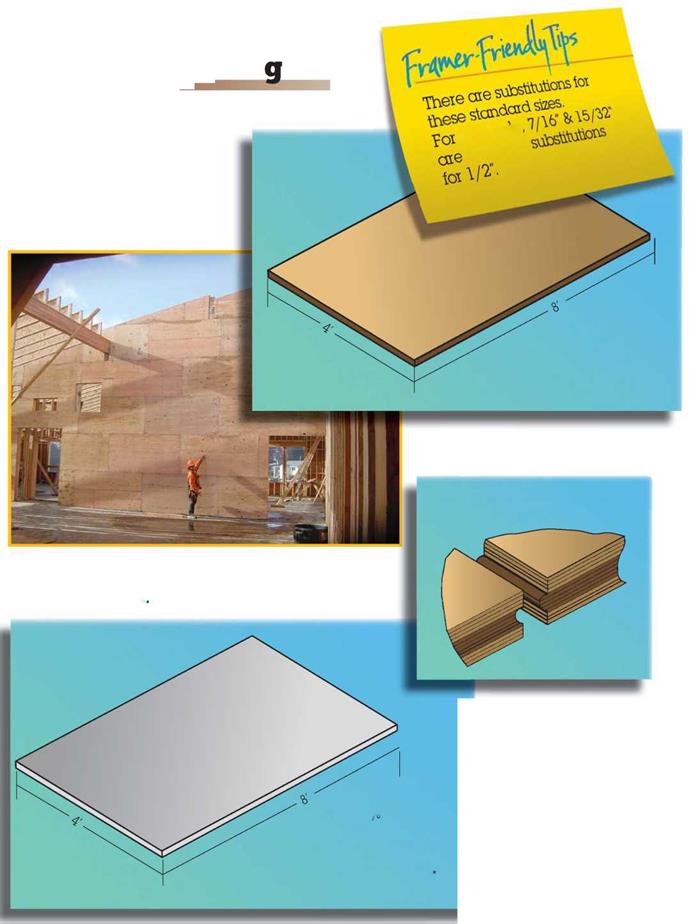

The engineered panel products on this wall provide the strength needed for the high ceiling of this elementary school

The engineered panel products on this wall provide the strength needed for the high ceiling of this elementary school

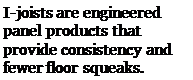

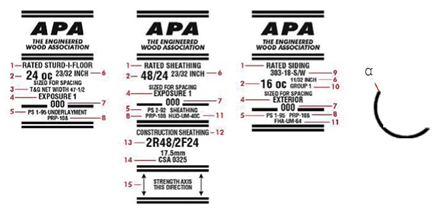

Dens Glass® gypsum sheathing is a brand that has fiberglass mat, which provides mold and moisture resistance and is gold in color.

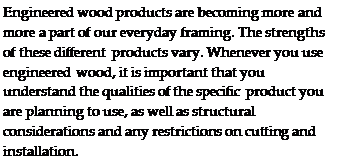

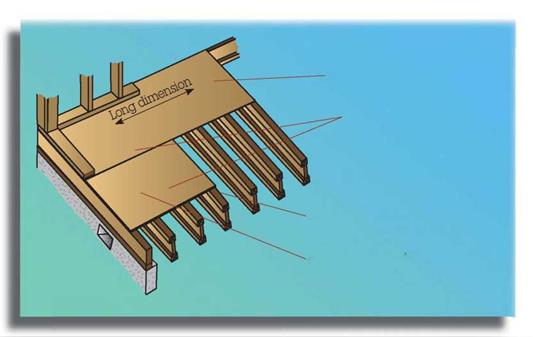

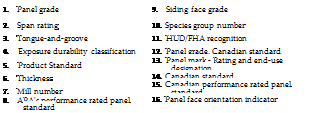

Engineered wood products can be divided into two categories: engineered panel products and engineered lumber products. Engineered panel products include plywood, oriented strand board (OSB), waferboard, composite, and structural particleboard. Engineered lumber products include I-joists, glu-lam beams, LVLs (laminated veneer lumber), PSLs (parallel strand lumber), and LSLs (laminated strand lumber).

Engineered wood products have structural qualities different than those of traditional wood, so they must be used within the specification set by the manufacturer. When these products are specified on the plans, the architect or engineer who specified them will have checked with the structural engineer to ensure proper use.

Engineered wood products have structural qualities different than those of traditional wood, so they must be used within the specification set by the manufacturer. When these products are specified on the plans, the architect or engineer who specified them will have checked with the structural engineer to ensure proper use.

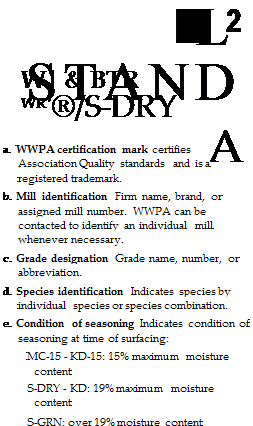

Engineered panel products have been around for years and are treated in a

![]()

|

|

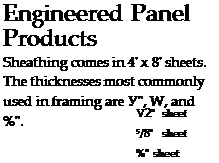

Engineered Panel

Engineered Panel

Stagger (optional)

Stagger (optional)

Leave space at all panel edge joints and У space at all panel end joints unless otherwise recommended by panel manufacturer.

2x joists, plywood-webbed I-joists or floor trusses.

APA rated sheathing

manner similar to engineered wood products. The 4′ x 8′ typical sheets are strongest in the direction of the grain. For floors and roofs, these sheets should be laid perpendicular to the direction of the supporting members. The strength of the panels comes from the panel cantilevering over the supports—so each piece should be at least as long as two support members.

Glu-lam beams, LVLs, PSLs, and LSLs can be cut to length, but should not be drilled or notched without checking with manufacturers’ specifications.

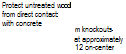

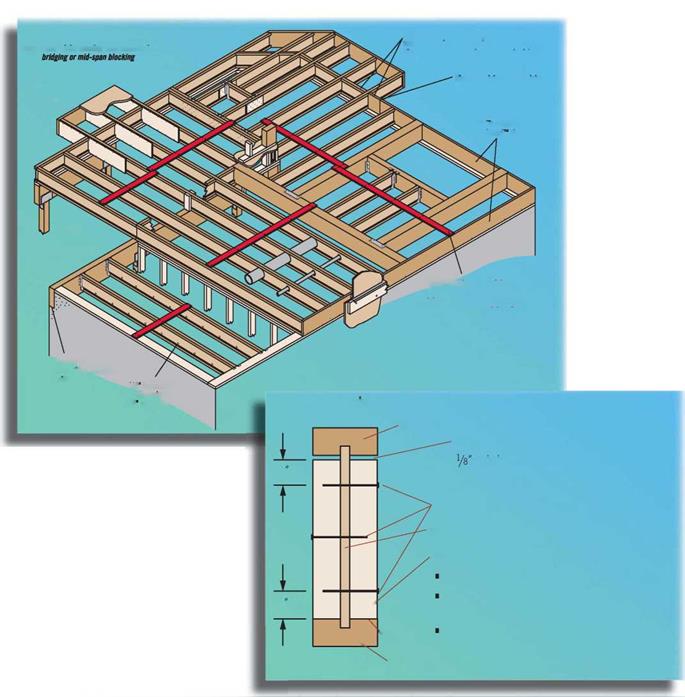

I-joists are becoming more widely used. Although the Engineered Wood Association has a standard for I-joists, not all I-joists manufacturers subscribe to that standard. Consequently, it is important to follow the manufacturer’s instructions whenever using I-joists. Installation instructions are usually delivered with the load for each job. The illustration shows some of the typical instructions.

Certain features are common among all I-joists. Rim and blocking may be of I-joist or solid rim board. Typical widths are 9%", 11 7/8 ", 14", 16", and 20".

Web stiffeners are used to add to the strength at bearing points. If the bearing point is at the bottom flange, then the web stiffener, which is the thickness of the flange on one side of the web, is held tight to the bottom. There should be at least a 1/8" space between the top flange and the web stiffener. If the bearing point is at the top flange, then the web stiffener is held tight to the top with at least 1/8" between the bottom flange and the web stiffener.

|

|

|

B1 on-center (61 on-center for Til® 110 |

|

|

|

|

|

|

|

|

|

|

|

|

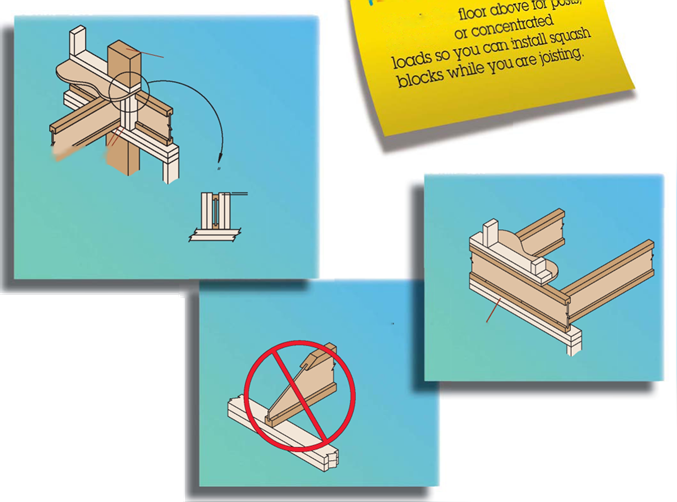

|

Squash blocks are pieces of lumber installed alongside TJI’s at points of heavy loading. They prevent the weight from crushing the TJI. They are typically dimensional lumber like 2 x 4s or 2 x 6s. They should be cut 1/іб" longer than the I-joist to take the load off the I-joists.

Squash blocks are pieces of lumber installed alongside TJI’s at points of heavy loading. They prevent the weight from crushing the TJI. They are typically dimensional lumber like 2 x 4s or 2 x 6s. They should be cut 1/іб" longer than the I-joist to take the load off the I-joists.

I-joists typically require a Ш" bearing. You can cut the end of an I-joist as long as it is not cut beyond a line straight up from the end of the bearing. However, no cuts should extend beyond a vertical line drawn from the end of the bearing point.

I-joist hardware, such as hangers, is usually delivered with the I-joist package. However, standard I-joist hardware can be purchased separately.

Check to-e

![]()

![]() coWirtoS,

coWirtoS,

V

2 x 4 minimum squash blocks (Illustrations courtesy of iLevel by Weyerhaeuser)

![]()

Squash blocks should be 1/16" greater than the I – joist height.

|

|||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

![]()

![]()

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

![]()

![]()

![]()

Leave a reply