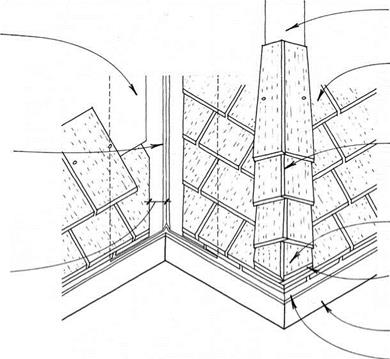

WOOD-SHINGLE VALLEY & HIP

|

|

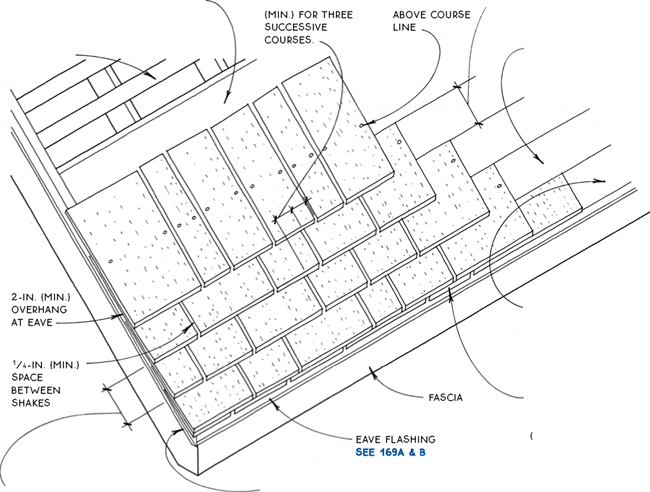

Wood shakes are popular for their rustic look and their durability. They are made from the same materials as wood shingles, but they are split to achieve a taper instead of being sawn. Shakes may have split faces and sawn backs or be taper-split with both sides having a split surface. In either case, the split side is exposed to the weather because it has small smooth grooves parallel to the grain that channel rainwater down the surface of the shake. Because the weather side of the shake is split, not sawn, and because they are considerably thicker, shakes will last a great deal longer than wood shingles made of the same material.

Standard shakes are 18 in. or 24 in. long and come in heavy or medium thickness. Wood shakes may be applied over open sheathing (see 166) or solid sheathing (see 163). The courses of shakes are usually alternated with an interlayment of 30-lb. felt that retards the penetration of moisture through the relatively large gaps between shakes. Solid sheathing and cold-climate eave flashing (see 169B) are recommended in areas that have wind-driven snow.

|

|

|

|

|

|||||

|

|||||||||

|

|||||||||

|

|||||||||

|

|||||||||

|

|

||||||||

|

|

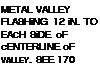

30-LB. FELT INTERLAYMENT LAPS VALLEY FLASHiNG.

![]()

![]()

note

note

wood-shake ridge is similar to hip.

Leave a reply