WOOD-SHAKE VALLEY & HIP

Clay tiles have been used in warm climates for centuries. Their use is still common in the southern extremes of this country, but they have recently been superseded by concrete tiles, which cost less and have better quality control.

Concrete tiles are made from high-density concrete coated with a waterproof resin. They are available in a variety of shapes and colors. Most tile patterns fall in the range of 16 in. to 18 in. long and 9 in. to 13 in. wide. Tiles weigh from 6 lb. to 10V2 lb. per square

foot (psf), which is about 21/2 to 5 times the weight of asphalt shingles. This extra weight may require that the roof structure be bolstered in some situations.

The cost of concrete tiles themselves is high compared to other common roofing materials, but most concrete tile-roof systems have a 50-year warranty.

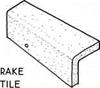

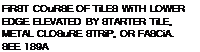

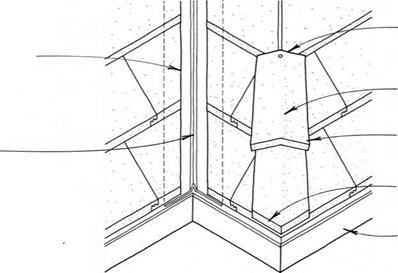

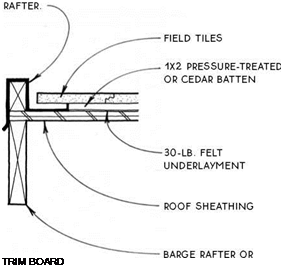

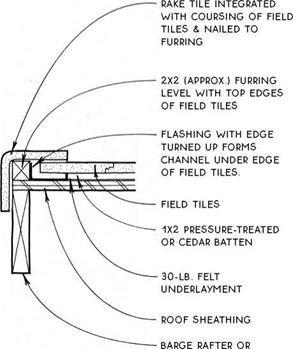

Most manufacturers recommend installing the tiles on solid sheathing with 30-lb. felt underlayment and pressure-treated nailing battens under each course. Course spacing is usually about 13 in., and can be adjusted to make courses equal on each slope of roof.

|

Introduction & Types of Tile

30-LB. FELT

underlayment

OVER SOLiD SHEATHiNG; FELT LAPPED 21/2 iN. AT HORiZONTAL JOiNTS, 6 iN. AT JOiNTS PARALLEL TO SLOPE.

|

![]()

![]()

![]()

![]()

![]()

STAGGER JOiNTS BETWEEN TiLES ON ALTERNATE COuRSES.

STAGGER JOiNTS BETWEEN TiLES ON ALTERNATE COuRSES.

дЛ CONCRETE-TILE ROOFING

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

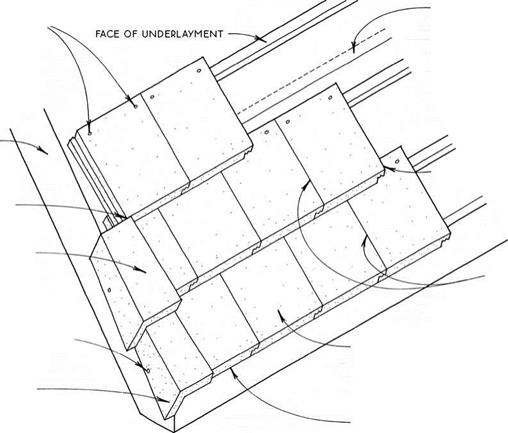

FLASHING WITH EDGE TURNED UP FORMS CHANNEL UNDER EDGE OF FIELD TILES & WITH DRIP AT BARGE

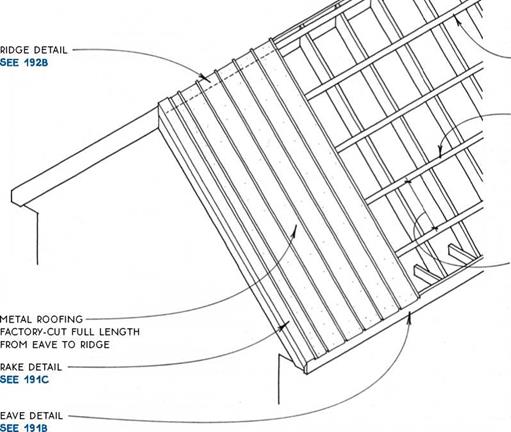

Low-cost metal roofs of aluminum or galvanized steel have been used for some time on agricultural and industrial buildings. The rolled metal panels are lightweight, long-lasting, and extremely simple to install. New panel patterns and new finishes have made metal roofing popular for residential and commercial buildings. A baked-on or porcelain enamel finish is often warranteed for 20 years, and the galvanized steel or aluminum over which it is applied will last for another 20 years in most climates.

Rolled-metal sheets are typically 2 ft. to 3 ft. wide and are factory-cut to the full length of the roof from eave to ridge. Because of the difficulty of field cutting at angles, metal roofs are best suited to simple shed or gable roofs without extensive valleys and hips. Small openings such as vents should be kept to a minimum and collected wherever possible into single openings. (Vents are best located at the ridge, where they are most easily flashed with the ridge flashing.)

The width of the roof itself should be carefully coordinated with the width of roofing panels so that rake

trim, dormers, skylights, and other interruptions of the simple system will be located at an uncut factory edge.

Because the metal roofing has structural capacity, it is possible to install the roofing over purlins, which are 2x’s spaced 2 ft. to 4 ft. apart. Most metal roofing panels will span 4 ft. or more, so the load on each purlin is great, and the design of the purlins that support the roofing is a critical factor.

A wide range of finish colors is available with coordinated flashing and trim metal. Translucent fiberglass or plastic panels that match the profile of some metal roofing patterns are also available as skylights.

Choose fasteners and flashing that are compatible with the roofing in order to avoid corrosive galvanic action. Care must also be taken to avoid condensation, which can occur on metal roofs. In cold climates, where proper ventilation of the roofing system does not suffice, a fiberboard backing covered with 30-lb. felt (installed parallel to the roofing panels) will insulate the roofing from moisture-laden air and also provide protection from what little condensation does occur.

|

|

|

|

|

|

|

![]()

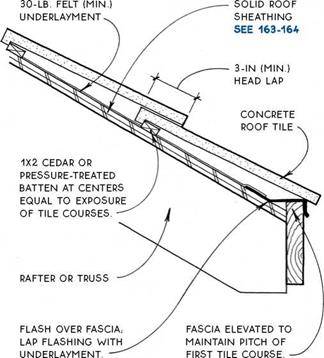

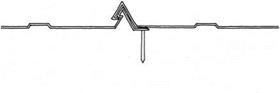

SCREW (OR NAiL) WiTH NEOPRENE WASHER LOCATED iN FLAT (VALLEY) PART OF ROOFiNG PROMOTES TiGHT SEAL OF wASHER.

SCREW (OR NAiL) WiTH NEOPRENE WASHER LOCATED iN FLAT (VALLEY) PART OF ROOFiNG PROMOTES TiGHT SEAL OF wASHER.

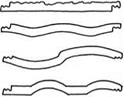

subsequent piEcE snap-fastens TO edge OF piEcE pREVIOuSLy NAILED. Flat-Head NAiL iS cOVERED SO neoprene washer is unnecessary. sections ARE NARROWER FOR this type.

screw (OR NAIL) WiTH NEOpRENE WASHER IS LOcATED ON RIDGE OF corrugation because VALLEYS ARE NOT WIDE OR FLAT ENOuGH.

IT’S difficult to adjust

TENSION OF NAiL OR ScREW.

Leave a reply