Wall

|

T |

he walls of a building serve several important functions: They define the spaces within the building to provide privacy and zoning, and they enclose the building itself, keeping the weather out and the heat or cold in. Walls provide the vertical structure that supports the upper floors and roof of the building, and the lateral structure that stiffens the building. Walls also encase the mechanical systems (electrical wiring, plumbing, and heating). To incorporate all of this within a 4-in. or 6-in.-deep wood-framed panel is quite an achievement, so numerous decisions need to be made in the course of designing a wall system for a wood-frame building. There are two preliminary decisions to make that establish the framework for the remaining decisions.

wall thickness

Should the walls be framed with 2x4s or 2x6s? The 2×6 wall has become increasingly popular in recent years, primarily because it provides more space for insulation and allows for other minor energy-saving advantages (such as the ability to run electricity in a notched base, as shown in 73A). These advantages all come at some cost. A 2×6 wall with studs spaced 24 in. o. c. (the maximum spacing allowed by codes) uses about 20% more material for studs and plates than a 2×4 wall with studs with a code-allowed spacing of 16 in. o. c. On the outside, the sheathing has to be V2 in. thick (Tbs in. thicker than sheathing on a standard 2×4 wall). Inside, the drywall also has to be Vs in. thicker to span the 24-in. spacing between 2×6 studs. Thicker insulation costs more too. So, overall, 2×6 framing makes a superior wall, but one that costs more. Framing the exterior walls with 2x6s and interior walls

with 2x4s is a typical combination when the energy – efficient 2×6 wall is selected. Stud spacing of 2×4 and 2×6 walls may vary with loading, lumber grades, and finish materials; in this book, however, studs are assumed to be 16 in. o. c. in 2×4 walls and 24 in. o. c. in 2×6 walls unless noted otherwise.

framing style

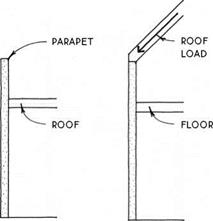

Should the walls be built using platform framing or balloon framing? Balloon framing, with studs continuous from mudsill to top plate and continuous between floors, was developed in the 1s40s and is the antecedent of the framed wall. In recent years, balloon framing has been almost completely superseded by the more labor-efficient and fire-resistant platform frame construction, with studs extending only between floors. There are still situations, however, where a variation of the balloon frame system is useful. One such situation is where the continuity of studs longer than the normal ceiling height is essential to the strength of a wall. Examples include parapet walls and eave (side) walls

|

|

that must resist the lateral thrust of a vaulted roof (as in a i^-story building).

Balloon-framed gable-end walls also provide increased stability in high-wind areas (see 160).

Another reason for using balloon framing is to minimize the effects of shrinkage that occurs across the grain of joists in a platform-framed building. This could be important with continuous stucco siding that spans two floors without a control joint, or in a multiple-story hybrid building system where the floors in the balloonframed part would not shrink equally with the floors in the platform-framed part.

Leave a reply