Site-built versus prefabricated stairs

Most stairs are site-built because it is economical and because the process provides a temporary stair for construction. But in some cases, stairs prefabricated in a shop are more practical. Prefabricated stairs (see 213C), whether simple or complex, can be made more solidly and precisely than site-built stairs because they are made in the controlled environment of a shop.

additional decisions

There are several other design decisions to make regarding both interior and exterior stairs. The primary decisions concern whether the risers are open (see 214A) or closed (see 216) and the design of the balustrade (see 218-220) and the handrail (see 221).

![]()

![]()

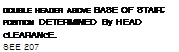

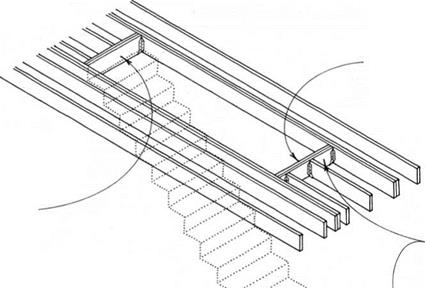

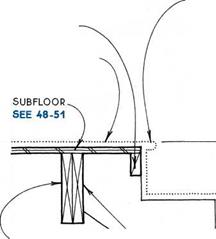

DOUBLE 2X HEADER AT TOP OF STAiR (DASHED); POSiTiON DETERMiNED ВУ METHOD OF CARRiAGE CONNECTiON SEE 212

DOUBLE 2X HEADER AT TOP OF STAiR (DASHED); POSiTiON DETERMiNED ВУ METHOD OF CARRiAGE CONNECTiON SEE 212

NOTE

wiDTH Of ROuGH OpENiNG DEpENDs ON wiDTH OF sTAiR; FOR sTAiR wiDTH, sEE 207. cODE REQuIREMENTs FOR wiDTH ARE FOR

clear openings, so allow for thickness of wall finish when dimensioning a rough opening.

д STAIR ROUGH OPENING

HEADER AT END OF STAiR ROuGH opening SEE 211A & 212

Top OF carriage/

FLOOR

SEE 212A, В & c

FOR FREESpANNING STAiR FRAMING,

SEE 213A & B.

FOR cARRiAGE FRAMING

at open balustrade, SEE 219 carriage framing/ side wall SEE 212D

NOTE

Top OF BASE OF STAiR MAy TERMINATE AT A FLOOR LEvEL OR A LANDING. THE STAiR FRAMING cAN BE THE SAME IN EITHER cASE.

|

|||

|

|||

|

|

||

|

|||

|

|||

|

|||

|

|||

|

|||

|

|||

Leave a reply