POCKET DOORS, BYPASS DOORS & BIFOLD DOORS

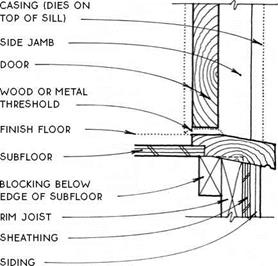

TRADITIONAL WOOD SILL WITH DRIP SLOPES AT 10° & REQUIRES THAT TOP OF RIM JOIST & COMMON JOISTS BE SHAVED OFF FOR INSTALLATION. SILL EXTENDS TO OUTSIDE EDGES OF DOOR CASINGS.

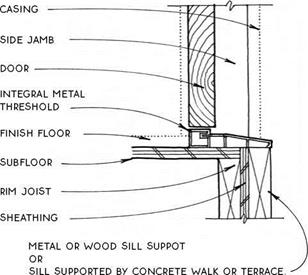

EXTRUDED SILLS OF ALUMINUM OR POLYCARBONATE ARE THE MOST COMMON FOR ALL MODERN DOORS. THE THRESHOLD IS INTEGRAL. THE SILL MUST BE SUPPORTED AT OuTER Edge. ExTRuDED SILLS May ALSO Be USED IN Slab-On-Grade cONSTRUcTION.

![]()

![]()

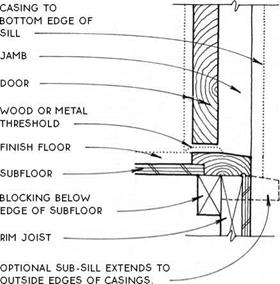

FLATTENED WOOD SILL SLOPES AT 7° & IS INSTALLED ON TOP OF JOIST SYSTEM. OUTSIDE EDGE IS FLUSH WITH JAMB (SHOWN) OR CASING.

NOTES

ADJUST PROFILE OF SILLS FOR OUTSWINGING DOORS.

WEATHERSTRIP BOTTOM OF DOOR.

WOOD SILLS ARE NOT COMPATIBLE WITH SLAB SUBFLOORS.

INTERIOR Flange cOORDINATES wiTH SILL & FINISH FLOOR.

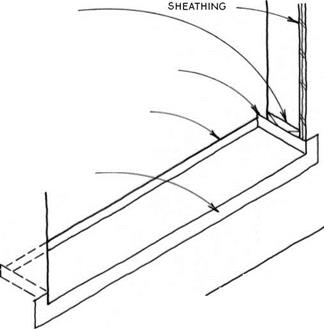

BOTTOM FLANGE OF PAN LAPS SHEATHING & DOOR wRAP.

NOTE MOISTURE BARRIER (NOT SHOwN FOR cLARITY) cONTINUOUS AROUND SIDES OF ROUGH OPENING & LAPS SIDES OF SILL PAN, SEE 89.

AT DOOR LOcATIONS ExPOSED TO THE wEATHER, A GALvANIzED METAL DOOR-SILL PAN FIT INTO THE DOOR ROUGH OPENING wILL PROTECT THE STRUCTURE OF A wOODEN FLOOR SYSTEM BELOw.

|

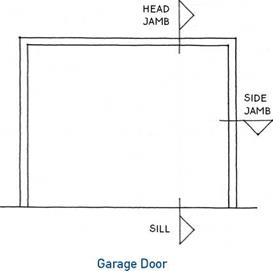

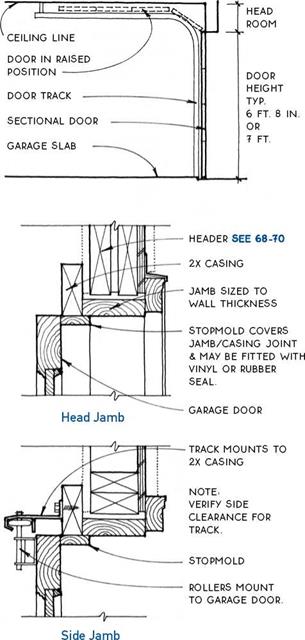

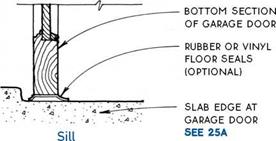

Residential garage doors have evolved from swinging and sliding types to almost exclusively the overhead variety. They are manufactured primarily with a solid – wood frame and plywood or particleboard panels. Paneled metal, fiberglass, and vinyl doors are available in some regions. There are two operating types, sectional and one-piece, both which can be manual or fitted with automatic openers.

Sectional doors— Sectional doors are by far the more common (see 101B). They are hinged horizontally— usually in four sections—and roll up overhead. The advantages are that a sectional door is totally protected by the structure when in the open position, and that it closes to the inside face of the jamb, making the design of the jamb opening somewhat flexible.

One-piece doors – One-piece doors pivot up. The door fits within the jamb and extends to the outside of the building when in the open position. This exposes the open door to the weather. The advantage of this type of door over a sectional door is the greater design flexibility afforded by the single-piece door. Hardware for this type of door is not usually available locally.

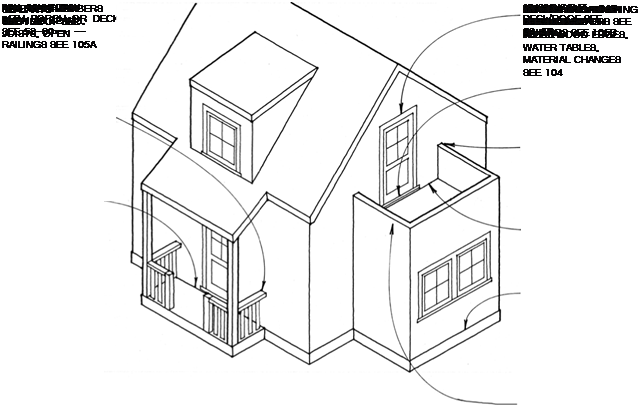

Flashing is essential to keeping water away from the structure and the interior of a building. It is used wherever there is a horizontal or sloped penetration of the outer building skin or a juncture of dissimilar materials that is likely to be exposed to the weather. Flashing provides a permanent barrier to the water and directs it to the outer surface of the building, where gravity carries the water down to the ground. Of course, the best protection against water penetration of walls is an adequate eave, but wind-driven rain may make this strategy occasionally unreliable.

Wall flashing, which provides the first line of defense against water, should be taken very seriously, especially because walls, unlike roofs, are not intended to be replaced regularly. Wall flashing is likely to be in place for the life of the building.

Two physical properties affect the flow of water on vertical surfaces. The first property, gravity, can be used to advantage in directing water down the wall of a building. The other property, surface tension, creates capillary action that results in water migrating in all directions along cracks in and between materials. In

many cases, the negative effects of surface tension can be avoided by the proper use of a drip.

A drip is a thin edge or undercut at the bottom of a material placed far enough away from the building surface so that a drop of water forming on it will not touch the wall but will drop away (see 103A). Drips may be made of flashing or may be cut into the building material itself.

In the case of vertical joints, a sealant may be required to counter the effects of surface tension. Except for vertical joints that cannot be flashed effectively, a well-designed flashing (see 103-105) is always preferable to a bead of sealant.

Common flashing materials include galvanized steel, baked enamel steel, aluminum, copper, stainless steel, and lead. Because flashing materials may be affected in different ways by different climates, air pollutants, and building materials, the selection of appropriate materials is specific to each job. It is also important to isolate different metals when flashing to prevent corrosive interaction (galvanic action) between them. Consult with local sheet-metal shops for appropriate materials for specific applications.

Leave a reply