PITCH-CHANGE FLASHING

![]()

wall sheathing on framing of wood flue

wall sheathing on framing of wood flue

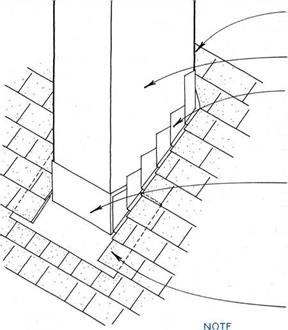

STEp FLASHiNG WOVEN WITH ROOFiNG COuRSES

(shown before it is lapped with moisture barrier & SIDING), SEE 171C,

OR

ALTERNATIVE SIDEWALL FLASHiNG, SEE 171B.

BASE FLASHiNG WRApS CORNERS, ExTENDS uNDER SHINGLES AT SIDES 4 IN. (MIN.) & LApS SHINGLES AT BASE 4 IN. (MIN.)

OR

ALTERNATIVE OuTSIDE CORNER FLASHiNG AT BOTH CORNERS, SEE 172A,

COMBINED WITH ABuTTiNG ROOF FLASHiNG,

SEE 169D.

|

|

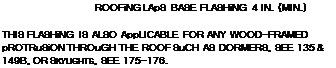

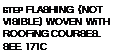

The flashing for a masonry chimney is best made of permanent materials such as copper or stainless steel. The flashing fits to the roof using the same principles as flashing for wood-framed flues (see 173B). The top edge of this flashing is then lapped with a counterflashing that is set into the mortar joints between masonry units. Because of the complex shapes, many of the pieces in chimney flashing cannot be folded but must be soldered or welded.

![]()

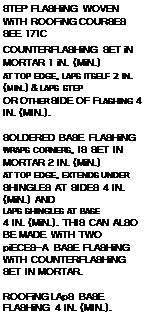

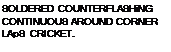

A chimney located in the slope of the roof will require a cricket (also called a saddle), a ridged connection

A chimney located in the slope of the roof will require a cricket (also called a saddle), a ridged connection

between chimney and roof that directs water

![]()

![]()

away from the chimney. Most crickets may be formed with exterior-grade plywood; larger crickets may need to be framed like a typical roof. The entire surface of the cricket is flashed, as shown in the drawing below.

away from the chimney. Most crickets may be formed with exterior-grade plywood; larger crickets may need to be framed like a typical roof. The entire surface of the cricket is flashed, as shown in the drawing below.

![]()

![]()

![]()

![]()

SOLDERED CRICKET WRApS CORNERS, EXTENDS UNDER ROOFiNG 6 IN. (MiN.) AND TURNS Up AGAINST CHIMNEY 4 IN. (MIN.).

SOLDERED CRICKET WRApS CORNERS, EXTENDS UNDER ROOFiNG 6 IN. (MiN.) AND TURNS Up AGAINST CHIMNEY 4 IN. (MIN.).

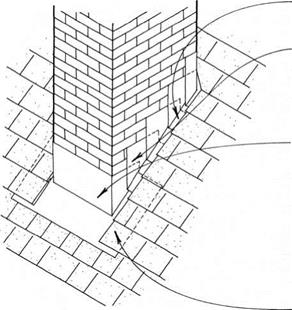

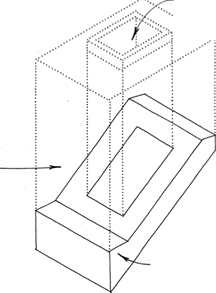

In severe climates, a through-pan flashing that extends continuously through the chimney should be considered. Through-pan flashing prevents water from migrating through the masonry to a level below the flashing. It is made of lead or copper and is penetrated only by the flue. It is wrapped down at the edges, where it acts as counterflashing. The continuous flashing through the chimney does weaken the masonry bond, so this flashing should not be used in earthquake or hurricane zones.

![]()

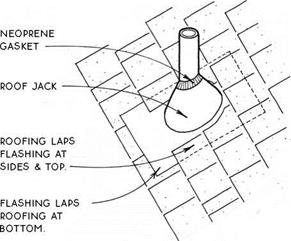

Modern roof jacks are typically fitted with neoprene gaskets sized to seal plumbing vents and other roof penetrations. Jacks are woven in with roofing materials where possible. Jacks for metal roofs pose special problems.

Leave a reply