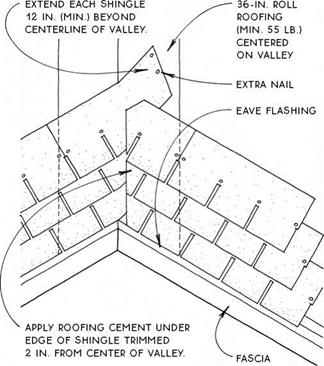

ASPHALT-SHINGLE VALLEY

|

|

||

For centuries, wood shingles have been used extensively for roofing, and they continue to be very popular. However, with the advent of the asphalt shingle, they have recently lost their dominance as a roofing material. Furthermore, their use continues to decline because of cost increases and a drop in the quality of the raw materials.

Roof shingles are made predominantly from clear western red cedar, but are also available in redwood and cypress. They are sawn on both sides to a taper, and have a uniform butt thickness. Standard shingles are 16 in. long; 18-in. and 24-in. lengths are also available. Widths are random, usually in the 3-in. to 10-in. range. There are several grades of wood shingles; only the highest grade should be used for roofing.

In most cases, wood shingles will last longer if applied over open sheathing (see 166) because they will be able to breathe and dry out from both sides and therefore be less susceptible to rot and other moisture – related damage. Use solid sheathing and underlayment, however, for low pitch (3-in-12 and 3l/2-in-12) and in areas of severe wind-driven snow.

Chemically treated fire-rated shingles are available. They must be installed over solid sheathing that is covered with a plastic-coated steel foil.

|

|

||

|

|||

|

|||

|

|||

|

|||

|

|||

|

|||

|

|||

|

|

||

|

|||

|

|||

|

|

|

|

|

|

|

|

|

|

|

Leave a reply