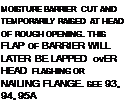

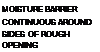

A WINDOW/DOOR ROUGH-OPENING WRAP

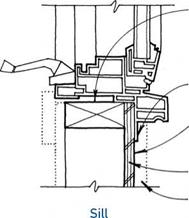

plastic or sheet-metal sill PAN provides alternative moisture protection in severe conditions. fasten pan only through sides and face flanges and lap sides with peel-and-stick flashing.

plastic or sheet-metal sill PAN provides alternative moisture protection in severe conditions. fasten pan only through sides and face flanges and lap sides with peel-and-stick flashing.

WINDOW/DOOR ROUGH-OPENING WRAP

Alternative Details for Severe Exposure to Rain

|

|

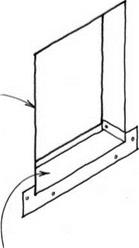

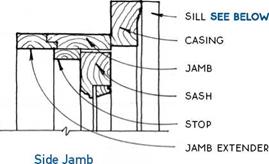

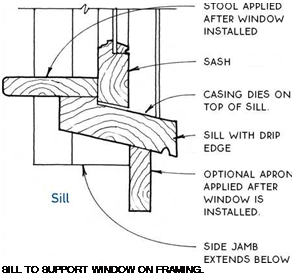

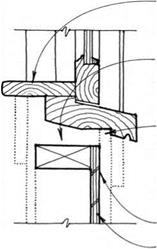

Modern windows derive from the traditional wooden window shown above. Older windows have a wooden sash that holds the glass, which is usually divided into small panes by muntin bars. This sash is hinged or slides within a wooden frame that is fixed to an opening in the wall. At the bottom of the frame is a wood sill, sloped to shed water. The sides and top of the frame are called jambs.

These components and their terminology have been handed down to the modern window, but modern windows are better insulated and better sealed, and usually need less maintenance than the traditional prototypes.

These components and their terminology have been handed down to the modern window, but modern windows are better insulated and better sealed, and usually need less maintenance than the traditional prototypes.

Today’s window is made in a factory and is shipped ready to install in a rough opening. Several popular types, classified by their method of operation, include casement, double-hung, sliding, hopper, awning, and fixed. Each of these types is made in wood, vinyl, metal, fiberglass, or a combination of these materials. Sizes and details vary with the manufacturer. Double-hung, sliding, and fixed windows are generally made in larger sizes than the hinged types. Optional trim packages are available with most.

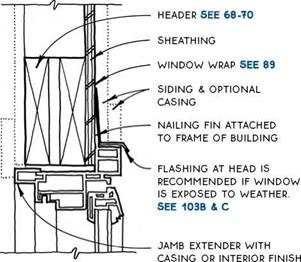

SHEATHING EXTERIOR WALL FINISH FLASHING SEE 103B & C

CASING

HEADER SUPPLIES STRUCTURE TO WALL ABOVE WINDOW OPENING. SEE 68-70

insulation fills IN void between window jamb & rough opening to insulate better &

TO RETARD AIR INFILTRATION.

SASH

SuPPORT WINDOW ON

framing according to manufacturer’s

SPECIFICATIONS.

moisture-barrier

WRAP PROTECTS

framing from water

LEAKS AROuND WINDOW. SEE 89

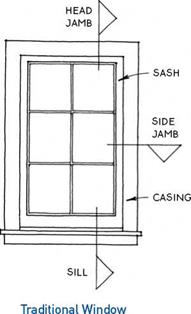

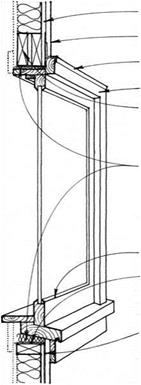

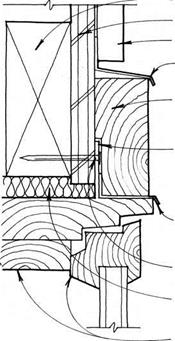

All windows require a coordinated installation in wood-frame walls, as follows:

Header— Size the header so that loads from above do not bear on the window itself, restricting operation.

Window wrap—Wrap the framing at the rough opening with a moisture barrier to protect it from any leaks around the edges of windows and doors.

Sill pan— At windows exposed to severe weather, add under the window a continuous metal or plastic pan that drains to the exterior (see 89B).

Shim and support – Shim the window at the sill and affix the shims to the framing so that the window is level and rests firmly on the framing.

Insulation—Place batt or spray foam insulation around the edges of the installed window to reduce both heat loss and air infiltration.

Air barrier—An air barrier, if used, must be sealed to the window unit. The moisture/air barrier may be sealed to the window nailing flange at the wall’s outside surface, or the vapor/air barrier may be sealed to the jamb’s inside edge at the wall’s inside surface.

Wood windows—Wood windows (see 92-95) are pleasing for their warm, natural look. Along with the excellent thermal properties of wood, the aesthetic appeal of the wood window is its strongest asset.

The major disadvantages of wood windows are the initial high cost and the ongoing need for maintenance. Wood is susceptible to deterioration from the weather, so periodically refinishing the exterior surfaces is necessary. Every effort should be made to protect all-wood windows from rain by locating them under overhangs.

Wood windows clad with aluminum and vinyl were developed to minimize maintenance. The cladding decreases their need for maintenance yet retains the aesthetic advantages of wood on the interior.

Vinyl windows—Made of extruded PVC that is either screwed or heat-welded at mitered corners, vinyl windows (see 93B and 94B) have come to dominate the window market. Their cost and expected maintenance are low, while their insulative properties are relatively high. They are available in all typical operating types.

Vinyl windows are not available with exterior casings, but decorative casings are often added (see 93B). One disadvantage of vinyl windows is the limited range of available colors. The vinyl cannot be painted, and only very light colors such as white and tan are available because dark colors tend to absorb heat, causing warping.

Fiberglass windows—Newly developed fiberglass windows have none of the disadvantages of competing materials, but they are currently quite expensive. Fiberglass does not deteriorate in the weather like wood and does not expand with heat like vinyl. It is a relatively good insulator and is so durable that manufacturers offer lifetime warranties. Fiberglass windows have factory-applied finishes, ranging from light to very dark, and can be painted.

Metal windows—Until recently, aluminum windows were the most common low-cost window. But energy codes and the popularity of vinyl windows have virtually eliminated aluminum windows from the residential market except in very mild climates. Aluminum is still available for commercial applications. The ubiquitous storefront windows are available in polished aluminum, anodized bronze, and a spectrum of baked-enamel colors.

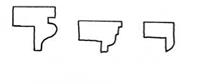

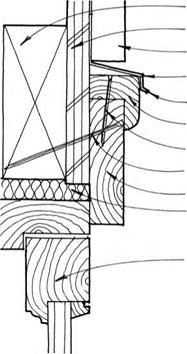

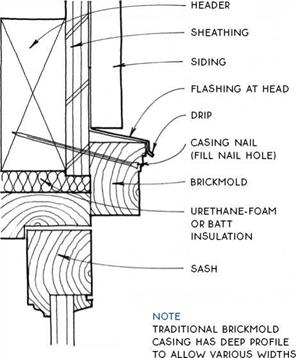

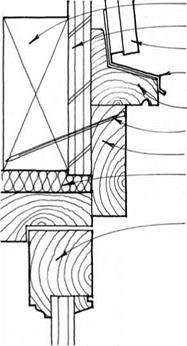

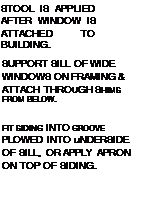

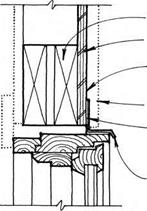

Unclad wood windows are attached to the building through the casing. This is the traditional way that windows have been fastened to wood buildings. The nail holes are typically filled, and the casings painted. It is also possible to cover the nails with a dripmold or with a backband that may be nailed from the side or the face, depending on the profile of the backband. The backband is mitered at the corners and dies on the sill.

Unclad wood windows are attached to the building through the casing. This is the traditional way that windows have been fastened to wood buildings. The nail holes are typically filled, and the casings painted. It is also possible to cover the nails with a dripmold or with a backband that may be nailed from the side or the face, depending on the profile of the backband. The backband is mitered at the corners and dies on the sill.

When attaching a window through the casing, it is important to support the weight of the window unit from below. Shim the sill and/or the extensions of the side jambs below the sill.

Some manufacturers also recommend blocking and nailing the units through the jamb. In this case, the nails can be covered by the stops.

HEADER

SHEATHING

SIDING

FLASHING AT HEAD DRIP

BACKBAND BACKBAND NAIL CASING NAIL CASING

URETHANE-FOAM OR BATT INSULATION

SASH

NOTE

BACKBAND COVERS THE CASING Nail IN THIN, Flat

casing & allows various widths of SIDING TO BuTT AGAINST IT. COvER BACkBAND NAILS WITH SIDING OR FILL NAIL HOLES.

|

|||

|

|||

|

|||

|

|

|

||

дЛ WOOD WINDOWS

|

|

||

|

|||

|

|||

|

|

|||

|

|||

|

|||

|

|||

|

|||

|

|||

|

|||

|

|

|||

|

|||

|

|||

|

|

|||

|

|

|||

|

|

|||

|

|

|||

![]()

![]()

![]()

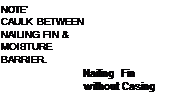

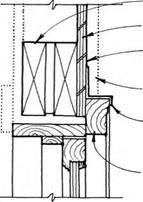

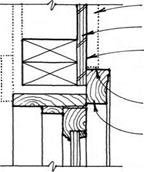

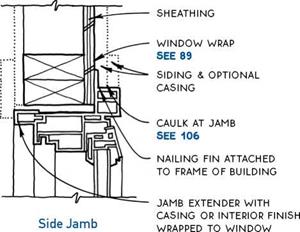

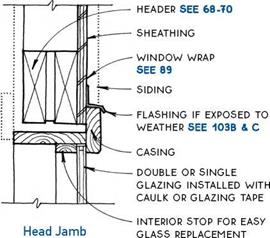

HEADER SEE 68-70

SHEATHING

WINDOW WRAP SEE 89

SIDING

NAILING FIN ATTACHED

![]()

to frame of building

to frame of building

|

|

|||

|

|||

|

|||

|

|||

|

|

|||

|

|||

|

|||

|

|||

|

|||

|

|||

|

|

||

![]() д CLAD WOOD WINDOWS

д CLAD WOOD WINDOWS

![]()

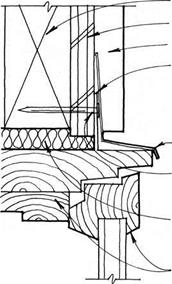

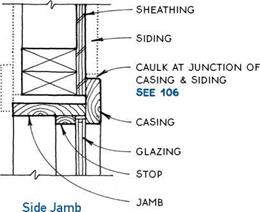

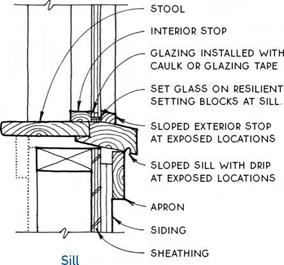

Where fixed windows are acceptable, a great deal of expense may be saved by custom-building the windows on the job without sash. In this case, the glass is stopped directly into the window frame, and caulk or glazing tape seals the glass to the casing just as it would to the sash. Ventilation must be provided for the space by means other than operable windows.

Where fixed windows are acceptable, a great deal of expense may be saved by custom-building the windows on the job without sash. In this case, the glass is stopped directly into the window frame, and caulk or glazing tape seals the glass to the casing just as it would to the sash. Ventilation must be provided for the space by means other than operable windows.

When designing and installing site-built fixed windows, the following guidelines are useful:

1. Allow Vs in. minimum clearance at the top and sides of the glass.

2. Rest the base of the glass on setting blocks spaced one-quarter of the width from each end.

3. Glass can be set closer to the interior of the building than shown in 95A by using exterior stop.

U. Support the sill of wide or heavy windows by shimming it from the framing.

Leave a reply