TRUSS ROOFS

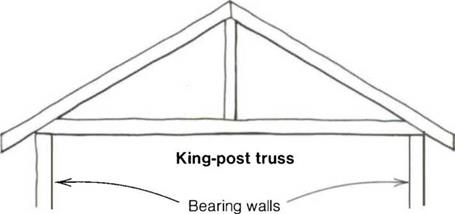

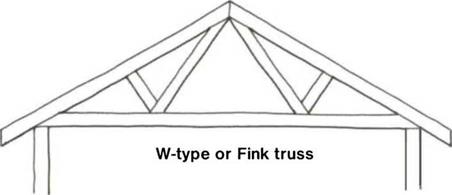

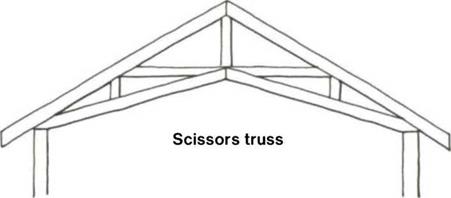

Truss roofs are engineered structures built in a factory. They combine the roof rafters (top chord) and ceiling joists (bottom chord) into one unit. Wooden braces, called web members, run between the chords, adding strength to the truss. Because of this, trusses can span long distances, bearing only on the outside walls. So rooms can be larger and door headers smaller than in a stick – built roof because they are not supporting ceiling joists or rafters.

Trusses can be built in many shapes and

|

designs to fit most any house (see the drawing on p. 136). In general, they require less lumber and labor to build than conventional stick-built roofs and can be installed quickly on the job site. This is especially important in areas where you want to seal off a house quickly from rain or snow.

Trusses also work well on remodel jobs. With proper planning, I have torn off an old, sagging roof and replaced it with new trusses in one day. Besides impressing the homeowners, I didn’t have to worry about rain coming down and soaking their dining-room table.

Trusses are carefully engineered, so cutting them in any way may fatally weaken their structural integrity. With

the exception of gable-end trusses, which have gable studs and are nailed in place directly over an end wall, trusses should not be cut without consulting the manufacturer or an engineer. Because of the web bracing in trusses, attics in most truss-roofed houses have limited storage space. Maybe this is one of the reasons public storage places have sprouted like weeds across our country.

Give yourself some lead time when ordering trusses. A busy company may not be able to get to your order for a week or so. I like to deliver (or fax) the truss plans directly to the company rather than order trusses over the phone. This helps avoid costly mistakes.

![]()

Trusses usually arrive on the job site banded in bundles of a dozen or more (see the top photo on the facing page). These can often be unloaded and set right up on the wall plates with a small crane or forklift If the walls are not yet framed and braced, be sure to stack the bundles on level ground. Trusses can withstand heavy vertical loads, but they break easily when bent too far horizontally. I recall working on a tract of houses where one set of trusses was left lying

Trusses usually arrive on the job site banded in bundles of a dozen or more (see the top photo on the facing page). These can often be unloaded and set right up on the wall plates with a small crane or forklift If the walls are not yet framed and braced, be sure to stack the bundles on level ground. Trusses can withstand heavy vertical loads, but they break easily when bent too far horizontally. I recall working on a tract of houses where one set of trusses was left lying

across a gully for a couple of weeks with the ridge section bending down. By the time they were ready to be installed, half of the gussets were pulled loose from the truss members. They were beyond repair and had to be reordered, holding up the framing on one house.

Most trusses are installed 24 in. on center (o. c.), so you’ll need plenty of 22У2-ІП. spacer blocks to nail between the rafters at the plate line and ridge. No truss layout is required on top of the walls because frieze blocks keep the trusses properly spaced. If these blocks aren’t supplied by the truss company, they need to be cut about Vs in. shorter than the standard 221/нп. block to allow for the thickness of the metal gussets that join the wood members together. Have some long 1xs handy also, laid out 24 in. o. c. These nail near the ridge to hold the trusses steady and to keep them on layout. If the trusses are long, tall, or both, you will need some long 2xs to brace them as you proceed. A strong gust of wind can topple unbraced trusses.

It is not easy to move a single truss from the ground up onto an 8-ft.-high wall, let alone a higher wall. To do so usually takes three people to keep the truss from bending and causing stress to the connectors, so it’s best to have the bundles set up on the walls when they are delivered. Lay the trusses flat on the walls with the ridge points sticking out over the end wall or stand them upright in the same location. Be careful when cutting the metal band that holds the bundles together. Under tension, a band can move quickly once it is cut and is sharp enough to slice a hand.

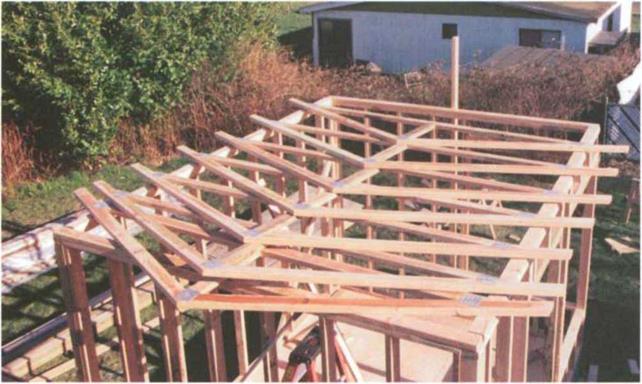

Individual trusses can now be laid flat across the walls in preparation for being nailed upright (see the bottom photo on the facing page). Experienced carpenters pull the first truss (a gable-end truss) off

|

|

In most cases, roof trusses arrive in bundles of a dozen or more, which can often be unloaded and set right up on the wall plates with a small crane or forklift. However, if the trusses are stored, be sure to stack them on level ground. (Photo by Elmer Griggs.)

|

|

In preparation for being nailed upright, individual trusses can be laid flat across the wall. The first truss has the ridge pointed outward, and subsequent trusses lay on top of the first about every 2 ft. like fallen dominoes. (Photo by Roe A. Osborn.)

Leave a reply