SAWS

Old-time carpenters needed many hand tools to cut and shape raw wood, such as the handsaw, keyhole saw, and miter box. Today’s carpenters use power tools, such as the circular saw, reciprocating saw, jigsaw, and miter saw.

The portable circular saw is as indispensable to a carpenter as a word processor or computer is to a writer. It is the one tool that you will use over and over again every day.

Circular saws come in two basic styles (see the photo below). One is a worm – drive saw with the blade on the left side. Direct-drive saws (also called sidewinders) have the blade on either the right or left side. Like many framers I know, I prefer the worm drive because it’s heavier, more durable, and delivers more power to the blade than the sidewinder.

For most carpenters, the average job can be handled by a heavy-duty 7У4-ІП. circular saw. For big work, such as timber framing, carpenters use a larger circular saw, called a beam saw. Beam saws are available with blade diameters of up to

|

When using power tools at home or on the job, make sure you plug them into quality extension cords. A good cord ensures that adequate electricity will be delivered to the tool you are using. So when shopping for an extension cord, don’t just buy the cheapest one on the shelf. A cheap cord can be dangerous.

In 1948, the year I first helped build a house, I was helping to finish a concrete slab in a basement. It was getting dark, so I asked for a light, and someone handed me a trouble light. It was trouble all right! I was standing with wet shoes on wet concrete. The extension cord supplying electricity to the light was frayed and ungrounded. The shock that went through me knocked me over backwards, and as I fell, I pulled the plug out of the outlet. Sometimes you get lucky!

BUYING GUIDELINES

When shopping for an extension cord, pay attention to the gauge (the diameter) of the wire. The smaller the gauge number, the larger the diameter of the wire. A 12-gauge wire is larger in diameter (or heavier) than a 14-gauge wire.

A corded power tool needs an extension cord with wires heavy enough to deliver adequate power to the tool. Imagine trying to water a lawn with a hose the diameter of a toothpick. Not much water will pass. When using a light-gauge extension cord, a power tool doesn’t get enough electricity. That means the motor will work harder, causing it to overheat and possibly burn out.

In general, a long cord requires a heavy-gauge wire to deliver the electricity with a minimal drop in voltage. As a rule of thumb, use 16-gauge wire for a 25-ft. cord. A 50-ft. cord needs at least 14-gauge wire, and a 100-ft. cord needs 12-gauge wire.

For protection against electrical shock while using a power tool, buy an extension cord equipped with a ground-fault circuit interrupter (GFCI). In the event of a short, or ground fault, the GFCI automatically shuts off power—and fast. (Many localities require GFCI protection on all job sites, so check your local codes.)

CARE AND STORAGE

Proper care of an extension cord is critical to making it last. Like a water hose with a hole in it, an extension cord (or a cord on a tool) with exposed wires can allow electricity to leak out, possibly into you. Take time to temporarily repair any cord that is frayed or cut by wrapping the area with electrical tape and by replacing the cord as soon as possible.

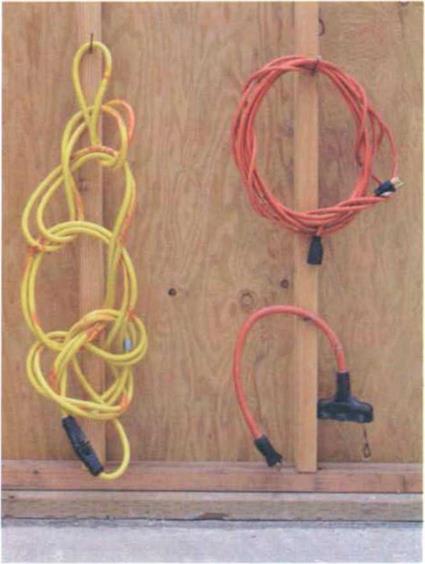

Another thing that will help an extension cord last— and remain tangle free—is proper storage. You can simply loop it into a circle and hang it on a hook. Or you can loop it into a daisy chain—which is a simple crochet stitch—and hang it on a hook.

|

Hang extension cords from hooks when not in use. To help ensure tangle-free cords, loop them into a circle (right) or a daisy-chain (left). |

1 б in. and are capable of cutting through б-in.-thick stock. Smaller circular saws for trimwork are available with blade diameters as small as 4Vi in.

While most circular saws come equipped with a steel blade, I recommend replacing it as soon as possible with a carbide-tipped blade. These blades stay sharp longer than standard steel blades, which makes cutting faster and safer. Most carpenters use a thin combination blade, which allows you to crosscut and rip wood easily. While not indestructible, most carbide-tipped blades will cut through the occasional nail without too much damage. But be sure to sharpen or replace a dull blade. A dull blade requires more pressure to make a cut, making the saw harder to control and creating more opportunities for accidents. Special blades for cutting materials like plastic, masonry, ceramics, tile, and even metal are also available.

Leave a reply