Portable table saw

When I first started framing back in the 1950s, the only power tool we had on the job was a table saw. It was a heavy monster with more iron in it than a John Deere tractor. It definitely was not portable. These days, table saws aren’t used much in framing, but they’re still very useful on the job site. Fortunately, these new machines are now so portable that they can be lifted with one hand. I find the table saw especially useful when it’s time for finish work. With it, I can easily and quickly cut siding and interior and exterior trim to size.

While these saws are convenient, they— like any tool—can be hazardous if used improperly. They’re light, so they should be secured to a work table at a comfortable working height. Once secured, the saw won’t move around during a cut, which decreases the possibility of kick – back. For safety, always stand to one side of the workpiece so you’re out of the line of fire in case the material kicks back.

As with any power tool, familiarize yourself with the manual before using it, and make sure the blade guard is in place and functioning properly before plugging the saw in. Also, raise the blade so that it projects only about Vs in. above the material being cut. Hold the stock securely against the fence when ripping, but, of course, keep your fingers away from the blade area. If the stock is longer than the table, set up a makeshift out-feed table or have someone support the opposite end as it comes off the table. Use a push stick to keep your hands clear of the blade as you finish the cut.

What the circular saw did for rough frame carpentry, the power miter saw did for finish trimwork. Just as the circular saw replaced the handsaw, the power miter saw replaced the miter box. The miter saw (often called a chopsaw) can make fast, accurate cuts in framing lumber, door and window casings, baseboard, and crown moldings.

The first miter saws I recall were used almost exclusively by plumbers to cut plastic pipe. Basically a circular saw mounted on a short table, a power miter saw is used to make square and angled cuts and has evolved into a tool that’s used daily by both frame and finish carpenters. Unlike a radial-arm saw, which slides along a track and is notoriously difficult to keep aligned, a power miter saw lowers into the cut with a chopping action from a fixed pivot point. The saw is rugged and easy to use and, when equipped with a high-quality blade, can make glass-smooth cuts. Blade diameters range from 8 in. to 16 in. Most carpenters prefer the 10-in. model,

A kickback occurs when the sawblade gets pinched in the kerf (the saw cut) and the power of the motor forces the saw backward. This can be a bit scary, and it is bound to happen to you if you use a circular saw all day.

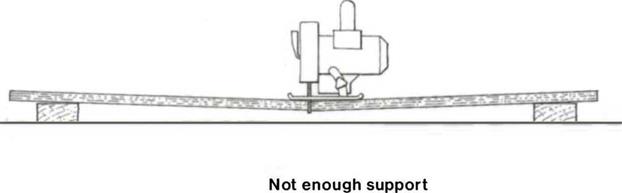

There are two keys to preventing a kickback. First, always cut in a straight line. Don’t try to force or twist the saw as you cut, which will cause the blade

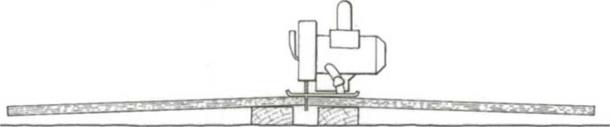

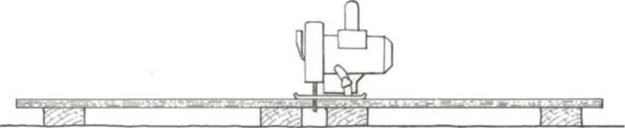

to bind in the kerf, kicking the saw out. Second, provide solid support for the stock on both sides of the cut. Without proper support, the stock will sag and pinch the blade, as shown in the drawing below.

If a kickback occurs, release the trigger on the saw immediately and allow the saw to stop. As long as the blade guard is working properly, there is little danger of injury.

|

|

|

The stock sags on the end, pinching the blade.

The stock sags on the end, pinching the blade.

|

|

|

Before using a circular saw, or any power tool, first study its manual, familiarize yourself with its parts, and follow the instructions on using and caring for the tool.

The blade guard of the saw should always move freely. If the guard is stiff, it could have a buildup of wood pitch on it. To remove the pitch, use bleach on the guard and brush off the pitch with a wire brush. Or better yet, try a common cleaner called Oxi-Solve on both (see Sources on p. 198). Before cleaning or testing the guard, be sure the tool is unplugged.

When you’re sure the guard is working properly, set the sawblade to the proper depth. In general, the blade should be set about Ve in. deeper than the thickness of the stock. Again, be sure to unplug the cord when setting the blade depth so that you don’t accidentally start the saw.

The three basic saw cuts used by carpenters are the crosscut, rip cut, and plunge cut. The key to making any of these cuts with a circular saw is being able to make straight cuts. With practice, this will become second nature, so grab some scrap wood—2×4 stock or plywood—and start cutting.

Leave a reply