INTERIOR TRIM

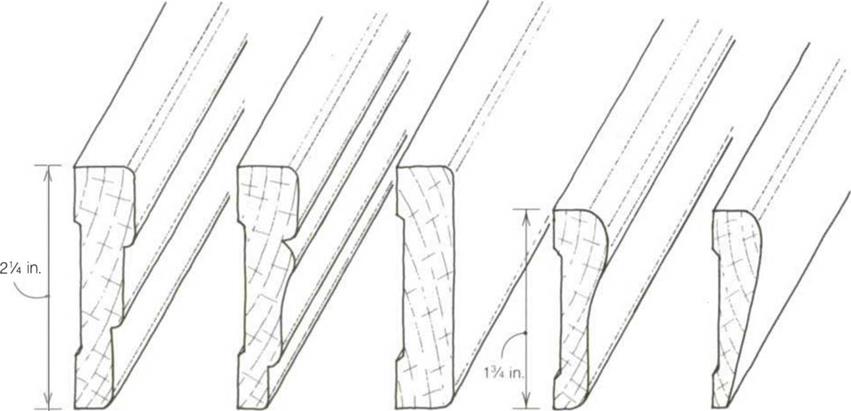

Once the drywall is up and the painters have sealed and finished the walls, the task of installing interior trim, window surrounds, casing, baseboard, and aprons can be started. Years ago we used to trim with wide baseboards, fancy casings, and elaborate crown moldings. While big-budget houses still often have these material – and labor-intensive trim details, the trend for more modest houses has been toward simpler and less expensive trim styles.

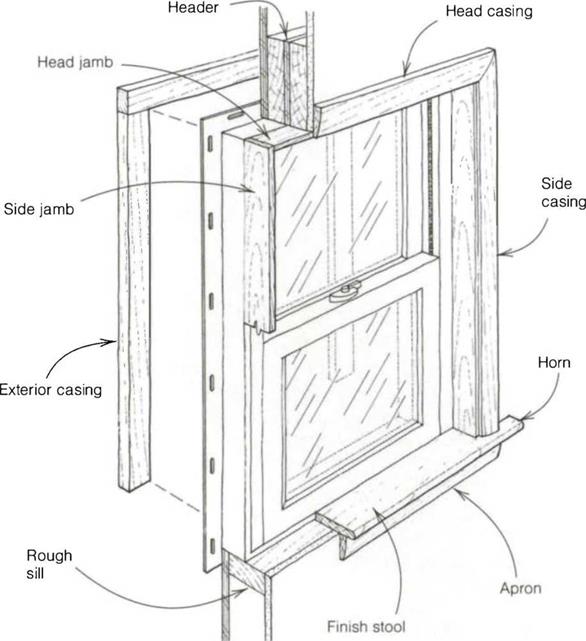

Unlike wood-framed windows, most vinyl-clad and aluminum-framed units don’t come with wood stools (often called sills) or wood jambs. Some people put in a wood stool and let drywall cover the wood trimmers and header. I like to make wood surrounds, or jambs, and

|

case them with trim. I think the wood gives a home a bit more warmth and style, and it’s not hard to do. [10]

horns depends on the width of the side casings, plus the amount the horns extend beyond the casings, usually about Уд in. (see the drawing above).

As a general rule, stools are wide enough to protrude about 1 У2 in. beyond the wall plane. But this can vary, and the window stool I have by my writing desk sticks out beyond the wall ЗУ2 in. and is wide enough to hold an open book. Many folks like an even wider stool in the kitchen to set flower pots in the sun.

After cutting the stool to length and laying out and cutting the horns, test fit it against the window. You want to make sure that the edge fits tightly against the window and that the horns fit tightly against the drywall; sometimes it takes some work with a block plane to get everything right. Although this is simple trim, every piece of trim in a house needs to fit just right to account for irregularities in the walls, floors, and ceilings.

Windows can often be ordered with jambs for specific wall thicknesses (for example, 2×4 or 2×6 construction), but sometimes you’ll need to cut and add jambs on the job. First, measure in from the face of the wall surface to the window frame in several places around the window. If these measurements are close, you can rip stock to this uniform width. I generally use a table saw and clean up the cut with a block plane. If the measurements vary widely, cut to

length a head piece that is wider than the wall thickness, then hold it in place at the top of the window and scribe a cutline by running a pencil along the drywall. Repeat the procedure with the side jambs. Jambs can stick out past the drywall about 1/ie in. to make a tight joint with the casing. Once properly fitted, nail the jamb head and sides to the rough header and trimmers with 6d finish nails.

Leave a reply