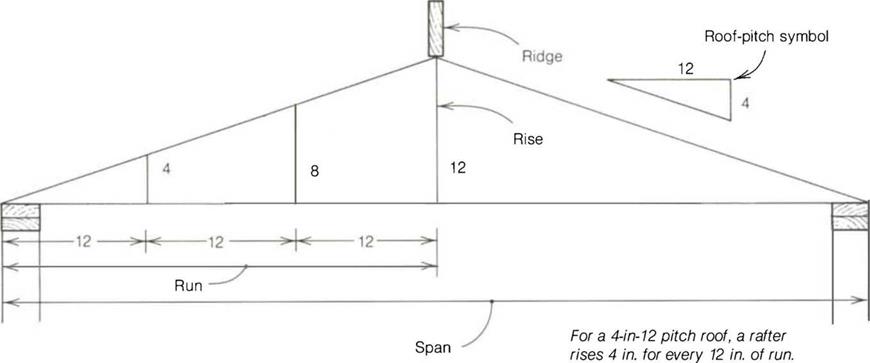

Gable-roof theory

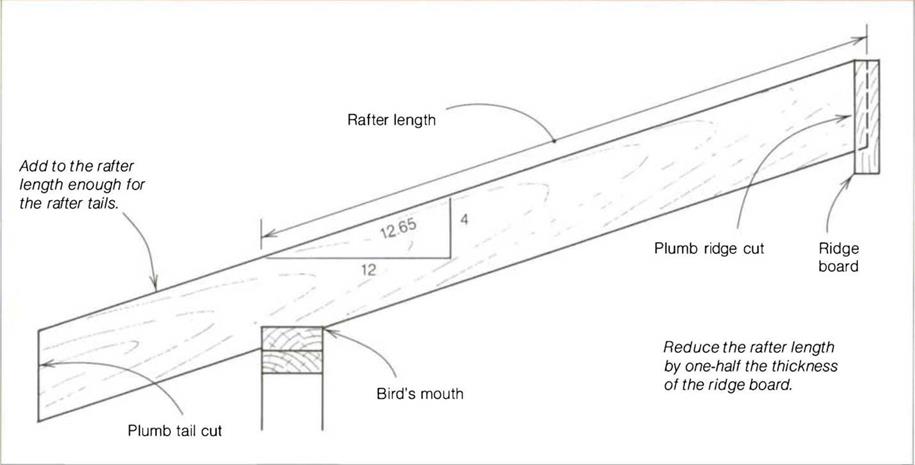

It’s also easy to determine rafter length with a calculator that has a square-root function. Knowing that a2 + b2 = c2 is the key (this is the Pythagorean theorem, the formula for finding the lengths of the sides of a right triangle). If the roof pitch is 4 (a) in 12 (b), then a2 (16) + b2 (144) = 160; the square root of 160 is 12.65. The length of the rafter (hypotenuse) for a 4-in-12 pitch roof with 1 ft. of run is 12.65 in. (see the drawing on p. 144). If the rafter runs 7 ft., for example, multiply 12.65 by 7 to get 88.55 in., or 7.379 ft. Converting the decimal to fractions gives you a rafter length of 7 ft. 414 in.

Laying out and cutting rafters

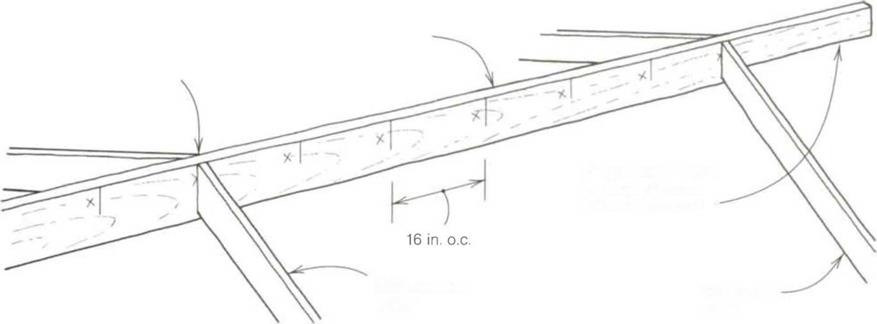

To determine the number, length (including enough for the rafter tail), and size of the rafters, you’ll need to check the plans. If the rafters are spaced 16 in. o. c., divide the length of the building by four, multiply this figure by three, and add one more. Double the result to cover both sides of the roof.

If the rafters are spaced 24 in. o. c., the process is even easier. Just take the length of the building and add two.

These days, rafters tend to be made from 2x8s or larger so that they can be filled with adequate insulation to meet energy codes and to support heavy roof tiles or snow loads. Many of the roofs I cut and stacked years ago were made from 2x4s and 2x6s. Recently, I got a call from a family who lived in such a house. One night they heard a horrible sound above, like something breaking, and asked if I would please have a look-see.

I crawled up in the attic, and they were right: Two rafters were split, and others were sagging. They had changed the roof covering from composition shingles to concrete tiles without adding extra supports to the rafters. Wet snow loads can cause the same damage.

Many buildings also have barge rafters (two on each end), that form the overhang on the gable ends. These rafters

are trim pieces that hang away from the building and are clearly visible to anyone who looks up. As you go through the rafter stock, lay aside four clean, straight pieces so that your trim will look good. But check the plans. Barge rafters may be smaller than the regular rafters or made from cedar, redwood, spruce, or pine.

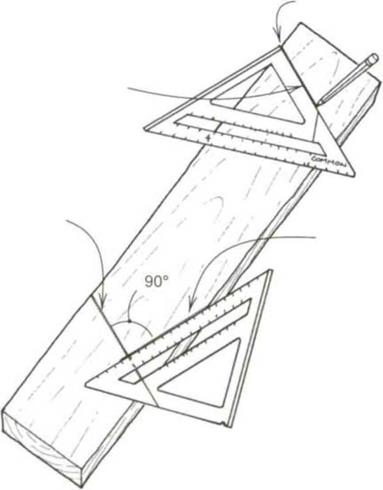

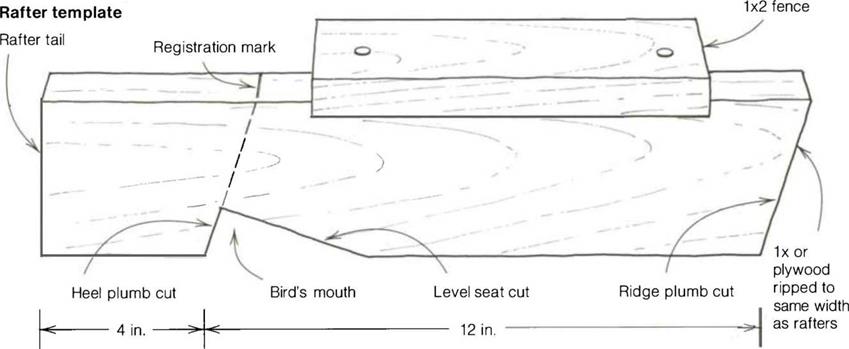

One of the fascinating aspects of building a roof is that all the rafters can be laid out and cut on the ground. Then, as perfect as a picture puzzle, the parts fit together on the house frame to form the roof. It seems rather magical, but it’s not difficult to do. Start at the beginning, by laying out a pair of common rafters on your sawhorses. First, though, make a rafter template out of scrap 1x or plywood that is the same width as your rafter stock (see the sidebar on the facing page), so that you won’t continually have to use your small rafter square to lay out the rafters. I use this template

to scribe the ridge cut (a plumb cut on the rafter stock that fits against the ridge board) and the bird’s mouth (the notch in the rafter that rests on the top wall plate).

To use the template, place it on rafter stock near one end and mark the plumb cut. Make sure the crown side is up. From the long point of this mark, measure along the top of the stock and mark the length of the rafter. Then align the template’s registration mark with the rafter-length mark and scribe the bird’s mouth. That’s all there is to it. Be sure you have enough stock left over for the tail forming the overhang.

With the first rafter marked to length, make the ridge cut with your circular saw. Move to the other end of the stock and make the cuts for the bird’s mouth, overcutting just enough to remove the wedge. Use this rafter as a pattern to lay out and cut the second rafter.

Use a small rafter square to scribe the ridge plumb cut at one end of the 1×6 template, as shown in the drawing at right. Move down the template about 1 ft. and scribe the heel cut (a plumb cut) of the bird’s mouth. Extend this line across the top edge of the template. This will serve as your registration or guide mark when laying out the bird’s mouth on the rafter stock. Then mark the level seat cut on the bottom edge of the template, which will be 31/2 in. long for 2×4 walls and 51/г in. long for 2×6 walls.

Add a 1×2 fence, and the template is ready for use (see the drawing below).

![]()

![]()

![]()

There is no need to lay out and cut rafter tails at this point. Instead, let the tails run long. Once the roof is built, a chalkline will be snapped across the rafters hanging outside the walls. The tails can then be cut in place, ready for fascia to be nailed to them.

There is no need to lay out and cut rafter tails at this point. Instead, let the tails run long. Once the roof is built, a chalkline will be snapped across the rafters hanging outside the walls. The tails can then be cut in place, ready for fascia to be nailed to them.

Before cutting up all the expensive rafter stock, it’s a simple matter to check to see that these first two rafters are cut properly. With a partner, pull up the two rafters, one on each side of the building. Hold them in place with the seat cuts snug at the plate lines. Place a short 2x ridge between the rafters at the peak, then check to see if all the cuts—both at the bird’s mouth and at the ridge board—fit perfectly. When you are satisfied, use the first rafter as a pattern to lay out and cut the remaining rafters. Once the rafters are cut, carry them to the house and lean them against a wall, ridge end up. Rafter tails will be cut to length once the roof is built.

Before cutting up all the expensive rafter stock, it’s a simple matter to check to see that these first two rafters are cut properly. With a partner, pull up the two rafters, one on each side of the building. Hold them in place with the seat cuts snug at the plate lines. Place a short 2x ridge between the rafters at the peak, then check to see if all the cuts—both at the bird’s mouth and at the ridge board—fit perfectly. When you are satisfied, use the first rafter as a pattern to lay out and cut the remaining rafters. Once the rafters are cut, carry them to the house and lean them against a wall, ridge end up. Rafter tails will be cut to length once the roof is built.

Like truss roofs, stick-built roofs have frieze blocks nailed between each rafter at the plate line that help stabilize the rafters. Cut the blocks slightly less than 141/2 in. long for rafters at 16 in. o. c. and slightly less than 221/г in. long for those nailed 24 in. o. c. If blocks are set on the wall, they may have to be cut 1 Vi in. shorter (13 in.) because of the ceiling joist nailed to the plate.

Laying out and installing the ridge board

Before tackling the ridge board and installing the rafters, take the time to build yourself a safe place to work. Nail plywood strips left over from the floor sheathing on top of the ceiling joists under the ridge line to make a catwalk that’s at least 2 ft. wide and that runs the full length of the building. There are times, especially when you have a high ridge or are working on a house without ceiling joists, that you will have to set up a scaffold. It’s best to use a solidly built metal scaffold (you can rent these) to guarantee your safety. Anytime you work high up, be safe. Risks are for trained Hollywood stunt men.

A secure catwalk gives you a place to lay out the ridge boards, which need to be as straight as possible. The ridge board must be wider than the rafter stock so that the angled plumb cut of the rafter bears fully across the face of the ridge board. So if the rafters are 2×6, use a 2×8 for the ridge board. Begin the ridge – board layout at one end, marking it

Leave a reply