Framing square

I learned to use the framing square when I was a carpenter in the Navy in the early ’50s. First introduced almost 1 50 years ago, the venerable framing square is still hard at work. Made of steel or aluminum, it has a 16-in. tongue and a 24-in. blade set at right angles to one another. Not an easy tool to carry in your toolbelt, it is nevertheless handy for quickly checking if walls are perpendicular to each other when setting cabinets and for marking square across 2×12 joists.

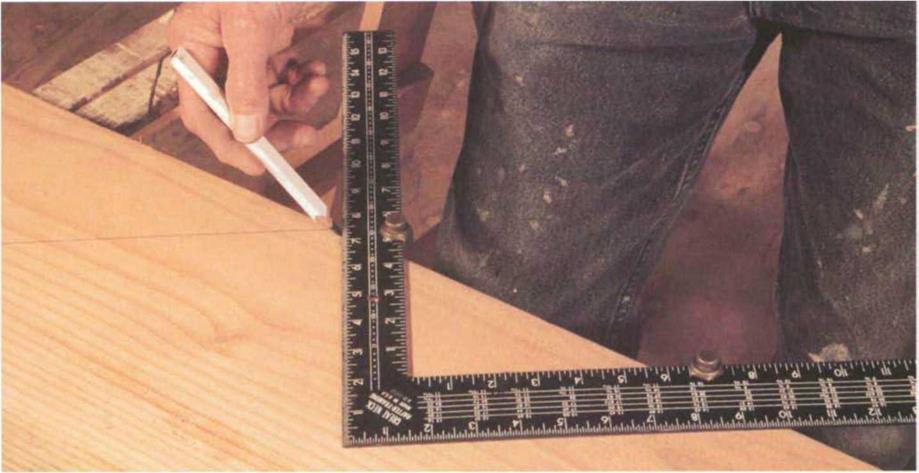

I use small stair gauges with my framing square when laying out stairs (see the photo below). The gauges are simply screw clips that are fastened to the edge

|

|

of the square, making it possible to mark the same angles on a stair stringer repeatedly.

Most combination squares have a 12-in. blade marked off like a ruler with a sliding head. One side of the head is used to lay out a 90° angle, and the other side is used to lay out a 45° angle. [1]

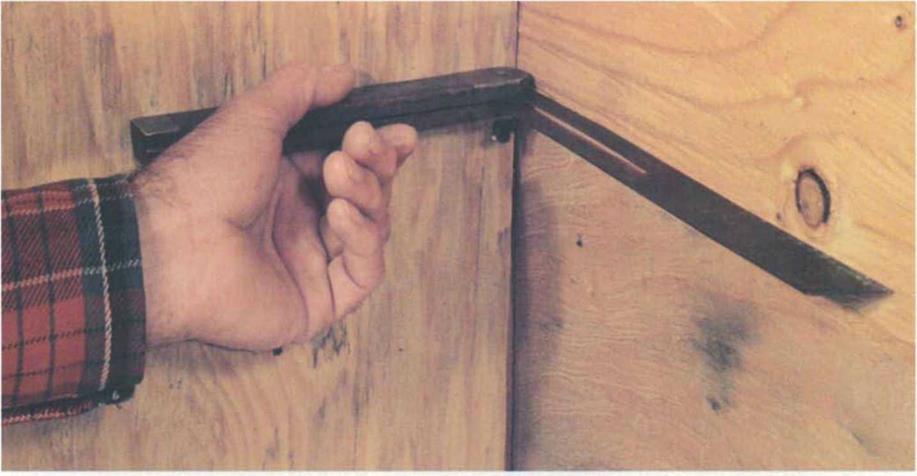

A T-bevel square has a blade that pivots and slides on a handle and can be locked in any position by a wing nut. I have one with an 8-in. blade, but many lengths are available.

This is an effective tool for fitting material to an odd angle. For example, you can use it to fit a shelf into a corner that is not 90° (see the photo above). First place the square in the corner with the blade against one wall. Then adjust the handle until it fits flat against the wall and tighten the wing nut. Nowyou can transfer this angle to the shelving, marking a precise cut. What makes the T-bevel square especially handy is that you can bring it right over to the chop – saw and use it to help adjust the angle of the blade exactly (unplug your saw before doing this).

A drywaller’s T-square is shaped like a "T" with a 22-in. tongue and a 48-in. blade that are both marked with inch scales. While usually used to mark sheets of drywall, this square is also a good tool to use when marking other sheet goods (like plywood) or doors for cutting. Just press the tongue along a square edge and mark along the long blade.

Treat the T-square with kindness. If you drop it, you can easily knock it out of square. To check for square, lay it across a sheet of plywood and mark along the

blade side. Then turn the square over and mark again. If the blade is not on the line, the tool is not square.

Leave a reply