FASTENERS AND HARDWARE

Carpenters don’t just use wood, nails, and screws for building. Many other types of metal hardware go into a house as well, and knowing what to use and when to use it can be baffling. Fortunately, most of the time we use only a few varieties on a regular basis. Here’s an overview of the basic types of hardware used by carpenters.

Nails are the most common fasteners used by carpenters because they are inexpensive and quick and easy to use.

Nail sizes When choosing nails, you have to think about the size you need, whether it’s for interior or exterior use, and how many you’ll need.

Nail sizes are dictated by the pennyweight system (abbreviated with a "d"). In general, a nail with a lower penny designation will be shorter and will have a thinner shank than a nail with a higher penny designation. For instance, an 8d nail is thinner and shorter than a 16d nail.

There’s no reason to drive larger nails than needed. I’ve seen carpenters nail doorjambs to studs with 8d nails when 6ds would have sufficed. If you are in doubt about the size nail needed, check with your building department. Many codes specify the minimum size nail needed for a particular job, how many to use, and where to drive them (this is typically called a nailing schedule).

Nails used inside the house aren’t exposed to the weather, so they usually don’t require coatings or treatment to withstand rusting. On the exterior, however, nails have to stand up to whatever Mother Nature throws at them. When nailing exterior siding, for instance, use nails that won’t rust and stain the wood, like hot-dipped galvanized (zinc-coated), stainless-steel, or aluminum nails. For holding power, choose ring-shank nails (nails with ridges) or screw nails.

Nails are purchased by the pound, so carpenters typically buy large quantities to save money. It’s cheaper to buy one 50-lb. box than it would be to buy five 10-lb. sacks. A typical 1,200-sq.-ft. wood-framed house can be nailed together with about 10,000 16d nails (200 lb.) and 5,000 8d nails (50 lb.).

Types of nails The type of nail you buy depends on the job at hand, and whether you’re framing or doing finish work. The nails a carpenter uses often are designated common, box, or finish.

Common and box nails are used mainly for framing. Box nails are thinner than common nails and are preferred for framing because they’re easier to drive. Many framers use what are called sinkers, which are nails coated with resin or vinyl. These nails drive easily and have good holding power.

The two most common framing nails are 8ds {2Vi in. long) and 16ds (ЗУ2 in. long). The 8ds are used to nail sheathing to floors or walls and cripple studs to headers, for example, while 16ds are used to nail together 2x stock, such as plates to studs.

Finish nails are used to nail trim boards like door casing and baseboard. These nails have small heads and can be driven below the surface of the wood with a nailset and the holes covered with putty. There are many different finish-nail sizes,

![]() the most common being 4d, 6d, and 8d. Brads are short (less than 1 in. long) finish nails. If nailing trim on the exterior, use aluminum, stainless-steel, or galvanized nails.

the most common being 4d, 6d, and 8d. Brads are short (less than 1 in. long) finish nails. If nailing trim on the exterior, use aluminum, stainless-steel, or galvanized nails.

There are also a number of different specialty nails. Double-headed (or duplex) nails are used in concrete formwork and for temporary scaffolding. The top head remains above the surface, making the nail easy to pull out. Hanger nails are short, hardened nails used to attach metal framing anchors (such as joist hangers) to wood. Masonry nails are used for nailing into concrete.

There are even plastic nails that can be used with pneumatic nailers (Utility Composites; see Sources on p. 198). Plastic nails have good holding power, won’t rust, can be cut with a saw, and can even be sanded with a belt sander.

The advent of the cordless screw gun has made screws the fastener of choice for many carpenters. Screws are used for everything from fastening sheet goods to installing trim and hardware. As with nails, don’t use a larger-size screw than you need, and if the screw is installed outside, choose a type that will stand up to the weather.

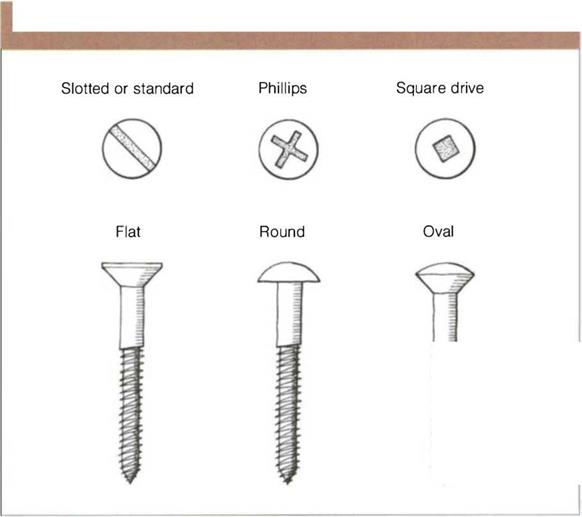

Wood screws can be used for all sorts of home-building jobs. Stores stock many types of wood screws, such as slotted, Phillips head, and square drive (see the drawing above). Standard lengths range from 1/4 in. to б in., and common gauges are 8 through 14 (the lower the gauge number, the thinner the screw shank). Head shapes are flat, round, and oval, and some are designed to be driven below the surface of the wood (called countersink heads). Most screws are made of steel, but aluminum, brass, and stainless steel are available. A standard

wood screw often requires a pilot hole so you don’t split the wood as you drive the screw.

For better or worse, drywall screws have replaced wood screws on today’s building sites. Although they were originally designed just to attach drywall to wood or metal, carpenters discovered that they have other uses. They are used so often that, when people ask for screws on a job site, they are usually talking about drywall screws.

Drywall screws (sometimes called bugle – head screws) have a Phillips head, range from 3A in. to 3 in. long, and usually have a flat black finish. With their thin shanks, deep threads, and sharp points, they can often be driven without a pilot hole. Drywall screws hold well and usually won’t split the wood, and their bugle-shaped, flat head countersinks itself in drywall or soft wood.

Leave a reply