Other fittings 14

Everything is excellent at such necessary devices, as turnaround valves. Only their design quite powerful and weight solid. To get rid of these defects, invented their facilitated models, so called interflange turnaround valves. The thought in general usual to be released from flanges on the device, and to fix it in flange connections of the pipeline. It is to a descent gives tangible benefit, a system the sizes of the device become even less, well and on weight such devices will be easier. However, such updating imposes also the restrictions.

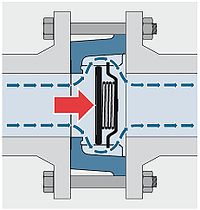

Fig. 1. Interflange spring disk turnaround valve.

But taking in attention that the prize in weight can be in times, in some cases and in 5 times, and the construction length is miniaturized even more, in some cases even in 8 times therefore, such restrictions are completely justified.

It is possible to remember that in the middle of turnaround valves, in particular small diameters, spherical turnaround valves are very popular. It is clear that in case of the interflange valve absolutely to embody this technology it is unreal, the basic locking element takes very bolshy place, and the place for a course still is necessary. Therefore, in interflange valves a sphere changed for a disk. Though the mechanism of work left same.

The mechanism of operation of that device is represented on fig. 2. As we contemplate, the spring at us is kept. Therefore, at sufficient pressure the valve reveals, and the working environment freely moves in the suitable direction. If pressure is not present, the valve is locked. In the same way, if the direction of a working environment changes, the valve remains in a closed position.

Fig. 2. Scheme of operation of the spring interflange turnaround valve.

From the scheme the fastening principle is clear also. It is possible to compare with the fastening scheme from previous article, and it becomes clear, at the expense of what that prize in weight and the sizes is received. Sphere substitution on a disk has also the next effect. As we remember, spherical turnaround valves are used only at small diameters of pipelines. Disk turnaround valves are used both on small, and on pipelines to 200 mm that is completely enough for household use.

Continuation follows …

Leave a reply