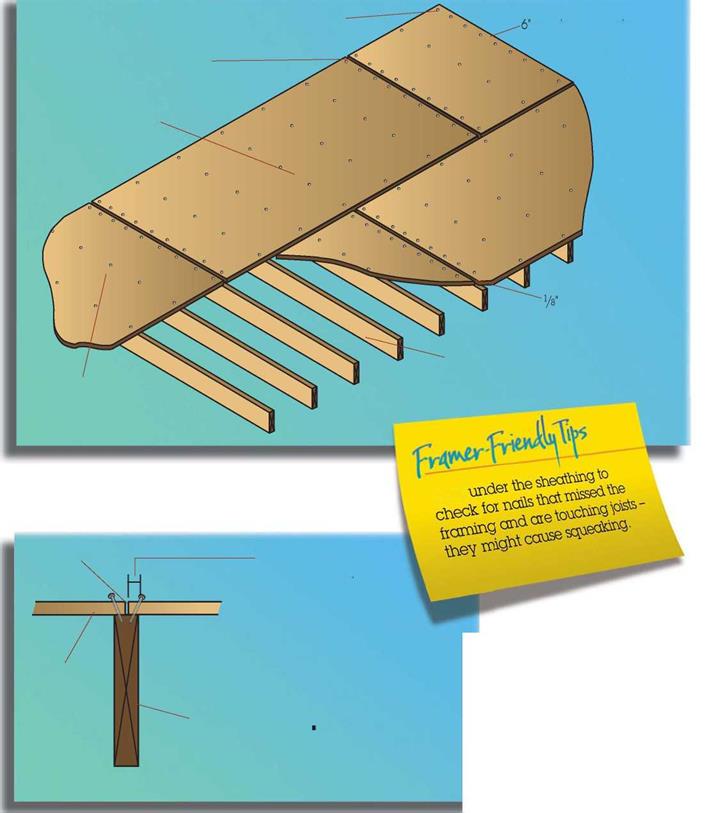

Nail Sheathing

|

|

|

|

Nail in 1У" from edge |

|

maximum spacing on edges – 9 nails |

|

1/з" space between sheets. (Increase spacing if sheathing is exposed to moisture.) |

|

12" maximum spacing in field – 5 nails |

|

space |

|

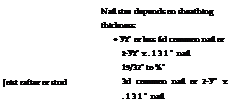

Joist rafter or stud |

|

Sheathing |

|

tOO^- |

|

Уз" space |

|

У2" from edge of sheathing to nail (No closer to edge than 3/8".) |

|

Sheathing |

|

Mark stud/joist/rafter spacing on the sheathing and then align the framing component with the mark before nailing. This ensures straight, evenly spaced framing. |

ends for better leverage. The longer the bar, the better the leverage.

ends for better leverage. The longer the bar, the better the leverage.

In America, there are around 58 million houses that were built before the last energy crisis. Because these pre-1970s houses have little or no insulation, they are all ripe for energy-efficiency improvements. Houses eat up 20% of the energy used in this country and account for 21% of the carbon dioxide that contributes to global warming. This adds up to a huge opportunity.

In America, there are around 58 million houses that were built before the last energy crisis. Because these pre-1970s houses have little or no insulation, they are all ripe for energy-efficiency improvements. Houses eat up 20% of the energy used in this country and account for 21% of the carbon dioxide that contributes to global warming. This adds up to a huge opportunity.