Block the Biggest Offenders

![]()

![]()

![]()

![]()

![]()

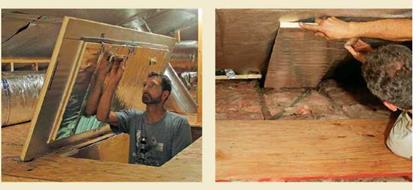

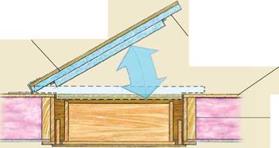

The attic access is a big leak that can be fixed quickly: Build or buy an insulated cover for the access bulkhead. The key is to provide a rim to connect to the sealing cover. The rim can be made from strips of sheathing, framing lumber, or rigid foam; then the cover sits on top or fits around the rim. On this job, I added a deck of leftover 1/2-in. plywood and OSB after the insulation was added.

The attic access is a big leak that can be fixed quickly: Build or buy an insulated cover for the access bulkhead. The key is to provide a rim to connect to the sealing cover. The rim can be made from strips of sheathing, framing lumber, or rigid foam; then the cover sits on top or fits around the rim. On this job, I added a deck of leftover 1/2-in. plywood and OSB after the insulation was added.

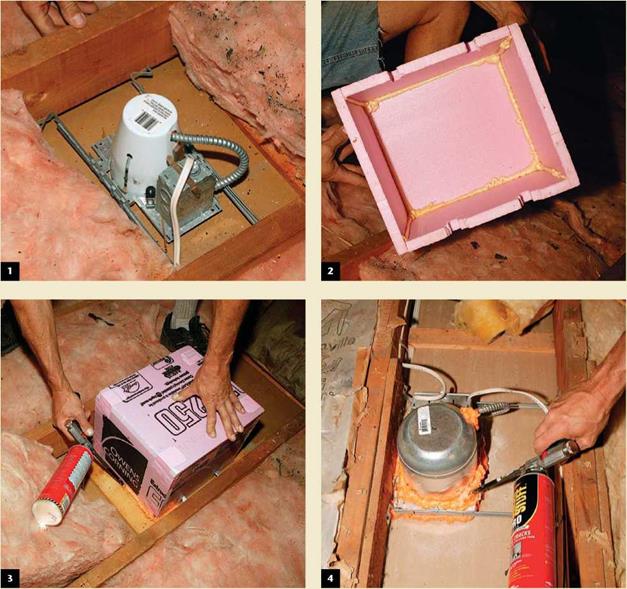

Interior soffits that are framed before the drywall is hung can leak huge quantities of air. Fill in the openings between the ceiling joists above the soffits with solid materials like rigid-foam panels, drywall pieces, or sheathing scraps, then seal the edges with expanding foam or caulk.

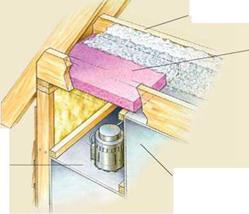

Joist bays should be sealed with rigid blocks to keep insulation where it belongs...

read more