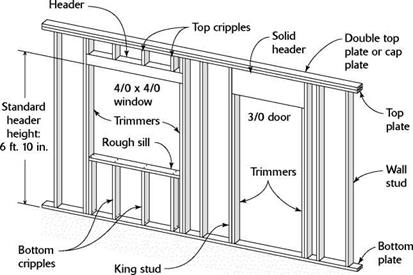

WALL FRAMING ANATOMY

STUDS are spaced on 16-in. or 24-in. centers. The length of the stud determines the overall height of the wall. Standard stud length is 92% in.

STUDS are spaced on 16-in. or 24-in. centers. The length of the stud determines the overall height of the wall. Standard stud length is 92% in.

KING STUDS are full-length studs used on either side of a door or window opening. They back up trimmer studs and are nailed against the ends of the header and (for window openings) to rough sill.

TRIMMERS (also called trimmer studs) frame the sides of rough openings. They extend along king studs to support ends of headers.

CRIPPLES, often called jack studs, span the distance between top plates and headers and between bottom plates and rough sills.

The BOTTOM PLATE is fastened to the floor deck or to a concrete slab floor.

The TOP PLATE is nailed to studs and cripples.

The DOUBLE TOP PLATE adds rigidity to the top of the wall and overlaps the top plate at wall intersections.

second is the height, and both are expressed in feet/inches. These dimensions are the actual door or window dimensions. To figure out your rough openings, you’ll have to add space for the jambs and trimmer studs. This is discussed in the following pages.

After you have a list of headers and all their dimensions for every opening in the house, you can cut and nail them together. Guidelines for sizing and building headers are explained in the sidebar on p. 84. If a door header requires cripples, mark their length on the header, then place the header along the plate where the doorway will be. On window headers, mark the length of the top and bottom cripples, then place each header near the plate location where it will be installed (see the photo at right).

Cut trimmers, rough sills, and cripples

Cut trimmers, rough sills, and cripples

Trimmers are cut and installed in pairs. The two trimmer studs set on the bottom plate support the ends of the header. Trimmers for 6/8 doors and windows are typically 801/2 in. long (81 in. in parts of the country where the

Before the walls go up, we start with a bare floor deck and lots of lumber. Pretty soon there are 2x4s in all directions. Making cuts with a handsaw is no picnic, so be sure to have a good circular saw on hand.

![]()

trimmers into account, the rough still for a window is 3 in. shorter than the window header. A 36 in. window with a 39 in. header gets a 36 in. rough sill. Tack rough sills to the header with one 8d nail, and make sure that the sizes of the window and cripples are marked on the header or sill. For windows that are 6 ft. or wider, you’ll need to double up on the rough sills and shorten the cripples by 1 /6 in.

Cut the cripples after you have cut all the headers, trimmers, and rough sills. Use a story pole, and make sure that your head is clear and your mind is focused. Making a mistake in the cripple length can result in window frames not fitting inside their openings, but you may not know that until all the walls have been built and raised. I once cut all of a house’s top cripples 1 in. too long. As a result, I had to remove every door and window header and shorten all of the cripples. Not a good way to start the week.

Cut enough top and bottom cripples to nail one on each end of every header and rough sill and one every 16 in. or 24 in. o. c., depending on the stud spacing. A chopsaw set up on a good work platform is great for cutting cripples (see the photo at right). A stop block, secured to the worktable or to an extension attached to the chopsaw, will enable you to cut identical cripples quickly and precisely.

Leave a reply