MAKE THE ATTIC ACCESSIBLE

Code requires an access hole for the attic. This allows workers to get into the attic to install insulation and wiring. You may also want to get up there some day to check on a roof leak or just to see how the spiders are doing.

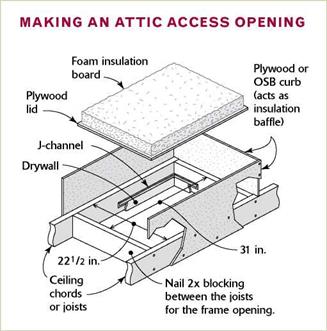

The standard attic access hole has a rough 2x frame that is 221/2 in. wide by 31 in. long. This rectangular opening fits nicely between ceiling joists installed on 2-ft. centers. Usually, the hole is located in a closet or along a hallway. Once you select a spot for access to the attic, cut a pair of 2xs to fit between the ceiling joists and nail them 31 in. apart. The bottom edges of the blocking should be flush with the bottom edges of the joists. Take the time to measure the hole diagonally to make sure it’s square. After V2-in. drywall is nailed in place, you will have a 21V2-in. by 30-in. access hole.

If you are using blown-in insulation to insulate the ceiling, build a plywood or OSB curb around the access hole in the attic. Make sure the curb is tall enough (at least 12 in.) to keep the insulation from falling on your head every time you open the lid to the

attic. The lid can be cut from drywall and should be insulated with rigid foam board.

Instead of a simple lid for the access hole, you may want to install a pull-down stair kit. If you’re using the attic for storage and need to go up there on a regular basis, a pull-down staircase is the way to go. The stairs are factory-made and designed to fit in the 22V2-in. space between the joists. The rough opening must be longer, however—54 in. is common. Check the manufacturer’s specifications before you frame the opening.

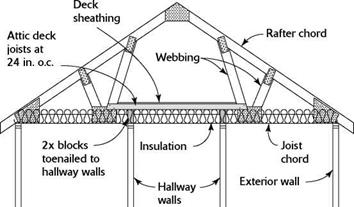

CREATE ATTIC STORAGE. There is some usable space in most truss-roof attics. To make use of it, don’t lay sheathing directly on the joist chords of roof trusses, as trusses are not engineered for this. Instead, frame a storage platform above the joist chords, making sure that there’s room for insulation beneath the platform. You can support the platform’s joists on short (8-in.- to 12-in.-long) cripple studs nailed to the double top plates of nearby walls. Sheathe the platform with 1/2-in. plywood or OSB.

Leave a reply