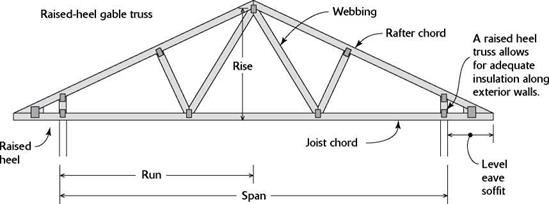

COMMON TRUSSES FOR GABLED ROOFS

![COMMON TRUSSES FOR GABLED ROOFS Подпись: Delivery right on the walls. It saves time and energy to have the truss company deliver the trusses and lay them right on the top plate of the framed walls. [Photo © Elmer Griggs]](/img/1312/image374_0.gif)

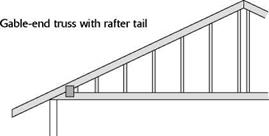

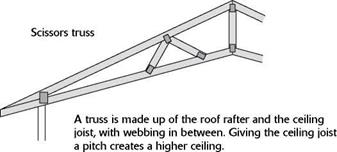

be open or closed. For details on different ways to finish off an eave, see the sidebar on p. 117. NUMBER OF TRUSSES. Roof trusses are typically spaced 24 in. o. c. Therefore, if your building is 40 ft. long, you’ll need to order 21 trusses. Two of the trusses will be for the gable ends. These trusses have studs rather than webbing to receive the exterior wall covering. SPECIAL REQUIREMENTS. If your house has a more complex roof, special trusses may be required where one roof section joins another. Often houses are built in a “T” or “L” shape or have a side porch that connects to the main roof. You can cut the rafters needed to tie the porch roof to the main roof. Another option is to have the truss builder look at the plans, check the span of these trusses, and build to your specifications.

STEP 1 PREPARE FOR TRUSS ARRIVAL AND INSTALLATION

When roof trusses are delivered to a job site, they can be offloaded onto the ground or onto the framed walls of the building (see the photo on p. 115). The choice depends on the builder’s preference and on the delivery truck’s capabilities. Experienced builders prefer delivery on the walls because it saves time. Trusses can be long and cumbersome. Putting them up on walls by hand can be difficult, dangerous, and time consuming. Most truss builders deliver the trusses on a boom truck. The boom can be used to set all the trusses directly on the walls. Plan ahead and order truss delivery the day after all the walls are framed and braced.

Whether your trusses are offloaded onto the walls or onto the ground, they need to lie flat.

I have seen trusses that were stored on uneven ground come apart at the seams, making them useless within a couple of weeks. Until they are nailed upright in place, braced, and sheathed, trusses are actually quite fragile. Prepare a flat area close to the house where the trusses can be offloaded. The bottom-most truss should not rest directly on the ground but on wood stickers that provide a flat, level base.

One of the most difficult parts of roof-truss installation is working high off the ground. It takes skill and practice to be able to stand on a narrow top plate and nail trusses to the wall. If this seems dangerous, or if you’re uncomfortable with it, try working on a ladder or a scaffold instead. To make it easy to move trusses into position, I like to build a catwalk, or walkway, over open sections, such as the living room. (For directions on how to erect a catwalk, see the illustration on p. 118.)

Before trusses arrive on the job site, take some time to lay out their locations on the top of the wall plates. Hook a long tape on the end of the

Leave a reply