BLOCKING IN BATHROOMS AND CLOSETS

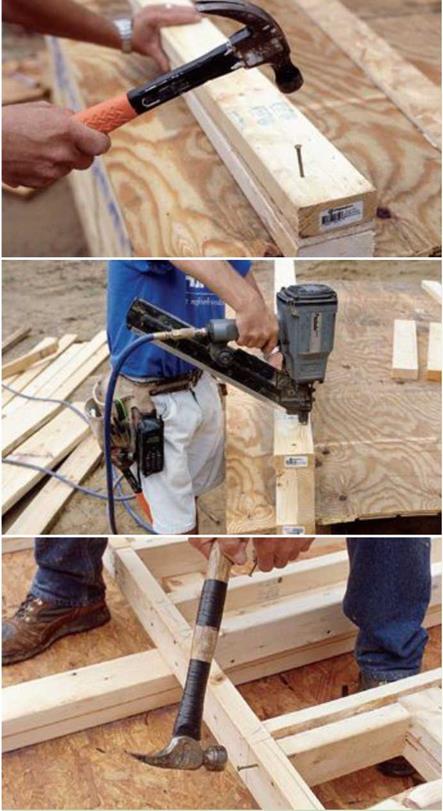

Nailed between studs, blocking provides solid backing for items such as towel racks, closet shelves, and safety grab bars. Blocking ensures that the mounting hardware for those devices can be anchored with screws driven into solid wood, so that you don’t have to worry about racks, bars, and shelves pulling loose.

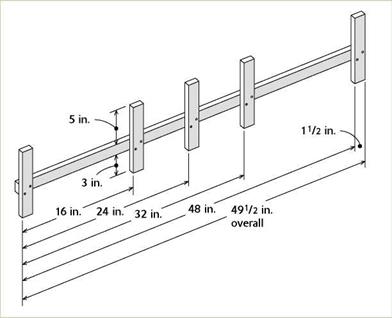

It’s smart to include blocking when marking up wall plates. Cut blocking boards from 2x scraps. As shown in the illustration at right, blocking is installed so that the face of the 2x is flush with the edges of the studs. To help locate blocking, use these standard heights for common bath, kitchen, and storage fixtures:

■ Towel bars: Near the tub and vanity, center blocks 54 in. above the floor.

■ Toilet-paper holder: Near the toilet, center blocks 24 in. above the floor.

■ Toothbrush and soap holder: Above the sink, center blocks 40 in. above the floor.

■ Safety grab bars: Near the toilet and near (or in) the bathtub/ shower, center blocks 36 in. above the floor.

■ Closet shelf and pole: Block 66 in. above the floor; more blocking may be needed if you install wire shelves.

and hold door and window frames together.

On the other side of the line, underneath the header, make a long, straight line along both plates to indicate that there will be an opening at that location and that no studs should be nailed there.

No matter what the plans indicate, keep interior wall headers at least ІУ2 in. away from corners and channels so you’ll have space on which to nail door and window trim. In hurricane and earthquake zones, exterior walls must not have window or door openings less than 4 ft. from an exterior corner, so that these sections of wall can be braced properly.

Above all, mark clearly. These plates will be pulled up and moved during framing. Clear marks improve the odds that all framing members will be attached accurately.

Use special markings to help other tradespeople

It’s important to remember that the framing must accommodate plumbing, heating, and electrical features. Talk to the subcontractors

BATHROOM STUD AND BACKING LAYOUT

|

before you even start on the floor. Show them your plans and find out what you can do when it comes time to frame walls so that they can do their work without having to remodel your structure.

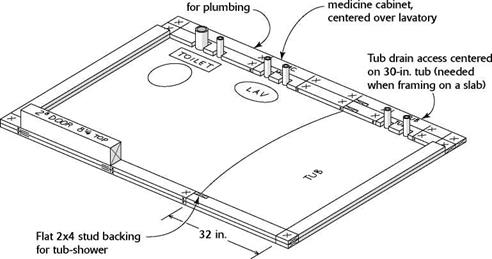

You can start by asking the plumber whether there’s anything you can do while laying out the bathroom to make it easier to install the pipes. The plate layout for a typical bathroom is shown in the illustration on p. 91. Code requires a mini

mum of 31 in. from sidewall to sidewall for a toilet. The wall behind a toilet is usually І2У2 in. from the center of the waste drain. Standard bathtubs are usually 30 in. wide and 60 in. long. If building on a slab, you may need a 12-in. by 12-in. access hole in the wall so the plumber can hook up or repair the tub trap. Measure 15 in. from the wall to the center of the tub trap and make a mark. Then measure 6 in. to each side of the mark (for a 12-in. hole) and strike lines onto the plates. Mark an “X” on the outside of these lines on both plates to show the studs’ positions.

Once a tub/shower unit has been installed, the plumber will nail it in place to a backing stud. Measure 32 in. from the corner and mark both plates with a keel. The stud location falls away from this mark. Toward the inside, mark the location of a flat stud that will be nailed to the first stud. The flat stud provides backing for the tub.

Plans often show an in-wall medicine cabinet centered over the bathroom sink. The standard rough opening for an in-wall medicine cabinet is 14І/2 in. wide. To accommodate one, measure 71/4 in. in each direction from the center (directly over the sink’s drain pipe) and mark across both plates with a keel, making an “X” on the outside of each line to indicate the studs’ locations. This will give you a 14//2-in.-wide rough opening for the medicine cabinet. Write “MC” on the plates between the two stud locations.

Include blocking requirements when marking up plates. As explained in the sidebar on p. 90, blocking between studs provides solid backing for important items, such as towel bars, built-in shelves, and so on, which will be installed after the interior walls are finished. If you’re building a porch, this is also the time to mark the location of any porch beams (see Chapter 6). Porch beams recess 3 in. inside the walls and require two trimmers underneath to support them.

I don’t know who made the first layout stick for marking stud locations, but I have been using one for almost 50 years. You can either make

one (see the sidebar on the facing page) or buy one (see Resources on p. 279). I learned how to do stud layouts with a long tape and a small square, but I think it is faster and easier to use a layout stick.

Take a look at the building plans. Exterior walls generally have studs spaced 16 in. o. c. Interior wall studs may also be spaced 16 in. o. c. but are sometimes 24 in. o. c. When exterior walls are sheathed with plywood or OSB, the studs are spaced to fit these 4-ft. sheets.

Start the stud layout at one end of a long exterior wall. Place the layout stick on the outside edge of the plates, with the first tab 3/4 in. beyond the end of the wall. This sets up a 16-in.- o. c. or a 24-in.-o. c. layout that will accommodate the 4-ft.-wide sheathing sheets (see the photo above). Mark both sides of the remaining tabs to note the locations of the next three studs. Move the layout stick, line up the end tab with the last mark, and mark again. If you’re nailing a sheet of OSB at the outside corners for bracing, make sure you lay out a stud 4 ft. from each corner in both directions.

Start the stud layout at one end of a long exterior wall. Place the layout stick on the outside edge of the plates, with the first tab 3/4 in. beyond the end of the wall. This sets up a 16-in.- o. c. or a 24-in.-o. c. layout that will accommodate the 4-ft.-wide sheathing sheets (see the photo above). Mark both sides of the remaining tabs to note the locations of the next three studs. Move the layout stick, line up the end tab with the last mark, and mark again. If you’re nailing a sheet of OSB at the outside corners for bracing, make sure you lay out a stud 4 ft. from each corner in both directions.

Leave a reply