ALL ABOUT HEADERS

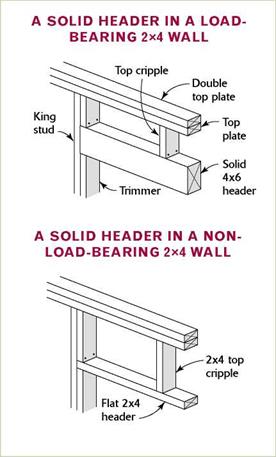

Spanning the distance above window and door openings, headers transfer the weight of the roof down through the trimmers, making it possible to have openings in a wall without compromising its strength. There are three things you need to know about headers: length, cross-sectional dimensions, and construction details.

Window and door manufacturers typically provide recommended rough opening sizes for the prehung units they sell. To determine the length of a window header, you can simply add 3 in. to the rough opening size; this is the combined thickness of the trimmers that support the ends of the header.

■ The length of a door header is usually 5 in. greater than the width of the door. Therefore, a 3/0 door (36 in. wide) needs

a 41-in. header. The extra 5 in. includes 3 in. for the trimmer thickness, 11/2 in. for two 3/4-in.-thick door jambs, and 1/2 in. of clearance space for setting the door plumb.

■ A set of sliding doors typically requires a shorter header than a regular door—just 3 in. longer than the combined width of the pair of doors. For example, a set of 5/0 (60-in.) sliding doors requires a 63-in.-long header, which provides 1У2 in. on each side for the trimmers. After the trimmers are wrapped with drywall, you’re left with a 59-in.-wide opening, which allows the sliding doors to overlap 1 in.

■  On the other hand, bifold doors require a header 4[1]/4 in. longer than the actual door size. So 5/0 (60 in.) bifold doors require a 64V4 in. header. The 4V4 in. margin leaves room for two trimmers

On the other hand, bifold doors require a header 4[1]/4 in. longer than the actual door size. So 5/0 (60 in.) bifold doors require a 64V4 in. header. The 4V4 in. margin leaves room for two trimmers

(3 in.), a layer of drywall (1 in.), and V4 in. so that the doors will close properly.

■ The standard header length for vinylframed windows is 3 in. longer than the rough opening (39 in. for a 36 in. window). For wood-frame windows, headers are cut 5 in. longer than the rough opening, just like door headers are. Make sure that the window sizes meet code requirements for daylight, ventilation, and egress.

Header Cross Section and Construction

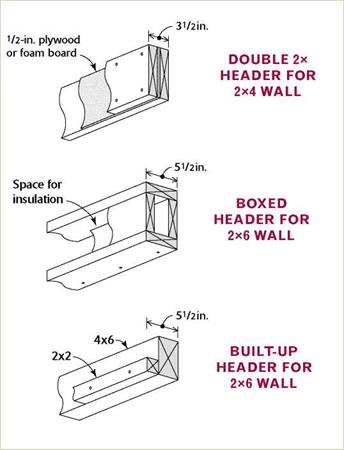

■ The header in a nonbearing wall can be a single 2x. In a load-bearing wall, the length a header spans determines its cross-sectional measurement. For a 3/0 exterior door or a 4/0 window in a 2×4 wall, code requires at least a 4×4 header. A 5/0 or 6/0 window requires

a 4×6 header. An 8/0 window needs at least a 4×8 header. In 2×6 walls, simply increase the thickness of the header to 51/2 in.

You can place the top plate alongside the bottom plate or toenail the top plate on edge to the bottom plate. These plating strategies maintain the alignment of the top and bottom plates so that you can accurately mark both plates at once.

Interior walls without bolts can be secured to a slab in various ways. You can drill through the plate and into the concrete with a cement bit. Once the hole is cleaned out, you can secure a bolt in the cement using epoxy or by using a bolt that expands as it is tightened.

Another common way to fasten a plate to a slab is by using a powder-actuated tool that shoots a hardened pin through the wood into the concrete. These tools pack serious power, so take care. Ask for training from your site supervisor before using them. Be sure to wear lenses to protect the eyes and plugs for the ears.

Leave a reply