Alternatives to Gypsum Board

Alternatives to paper-backed gypsum board are now available. The following products may be used to replace it and are especially useful in applications where moisture conditions may promote mold growth:

• Dens Armor Plus is an alternative to regular cardboard-backed panels. It is paperless, faced on two sides with a glass mat, and highly mold resistant.

• Magnesium oxide boards: Currently these products are being manufactured in China. They can be used to replace gypsum board, plywood, cement boards, and oriented strand board (OSB). They resist moisture, bugs, fungus, mold, and fire. Products are available in North America under the product names Dragonboard, MagBoard, and Strong-Enviro Board.

Tile is generally an inert and healthful floor, wall, and counter surfacing material. We recommend factory-finished tiles that require no further finishing onsite. Many attractive and reasonably priced tiles are rated for commercial and exterior use. This rating almost guarantees a low-maintenance, long-wearing product that will not require onsite refinishing.

The following concerns must be addressed in order to achieve a healthful installation:

• In standard construction, tile is often laid over an unacceptable backing such as particleboard, which contains high formaldehyde levels.

• In wet areas, tile is frequently laid over green board (a gypsum board that has paraffin wax mixed with the gypsum to prevent it from falling apart). However, the paper on the board will still develop mold in the presence of moisture.

• Certain imported tiles contain lead-based glazes or asbestos fillers. Lead content can be simply verified with a lead swab test (see Chart 13 л).

•  Certain glazes, primarily imports, have been found to be radioactive, especially cobalt blues and burnt oranges.

Certain glazes, primarily imports, have been found to be radioactive, especially cobalt blues and burnt oranges.

|

|

сокт

сокт

|

|

PBTAl МТЙ 4W ШШб"

ШпЖ

H^^NPV

&&, w>

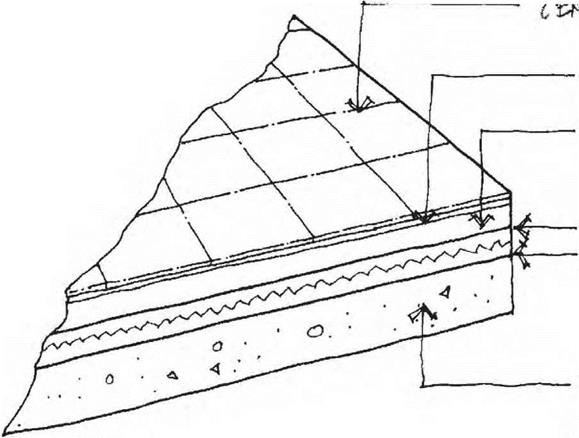

Thick-set tile installation.

• Many tile-sealing products contain harmful chemicals and high levels of VOCs. Selecting tiles with commercially rated finishes and glazes will bypass the need to use tile sealers on the construction site.

• Some standard tile adhesives and mortars contain harmful chemicals.

• Standard grouts usually contai n fungicides and latex additives.

• Grouts are porous and can harbor mold and mildew. They should be sealed where exposed to water.

The following are acceptable underlayments for ceramic tile:

• A clean, level concrete slab or gypsum concrete base that has been fully cured.

• Exterior-grade plywood that has been aired out and sealed. Use only where a cementitious underlayment is unavailable.

This method will require mastic adhesive and is not recommended for areas that get wet.

• A lightweight, strong, noncombustible, highly water-resistant cementitious board such as Durock, Hardibacker Board, or PermaBase.

The three basic methods for installing tiles are thicksetting, thinsetting, and adhesion with organic mastics.

Thickset Method

This is the tried and true, old-fashioned way of adhering tiles, prevalent prior to the invention of additives. A thick reinforced bed of mortar consisting of Portland cement, sand, and in some cases lime is floated. While the base is still plastic, a thin layer of Portland cement paste known as the bond coat is spread over

it. The tile is adhered to the bond coat and allowed to cure for several days before the tile is grouted.

This method will create the strongest, most durable tile installation available without the use of chemical additives. The following should be specified for this type of installation:

• Use only additive-free Portland cement, clean sand, lime where required, and potable water. Use the recommended reinforcing and specified cleavage membrane.

• For wall, ceiling, and floor installations, follow the method covered by ANSI AI08.1 and set the tiles on the mortar bed while it is still plastic.

• The cleavage membrane shall be nonasphalt-impregnated, 4 millimeter polyethylene such as Cross Tuff, Tu Tuf 4, or an approved equivalent.

It is not always possible to use a thickset installation. The iW-inch depth required for thicksetting may not be available unless carefully planned from the outset. Tile setters skilled in this method are sometimes difficult to locate. This method is labor-intensive and will be more costly than other installation methods.

Thinset Method

Tliinset mortars are powdered sand and cement products mixed with liquid and spread to a thickness of approximately Vs to Ys of an inch. Once dried they are unaffected by water and can be used in wet applications.

A variety of thinsets are available. Most thinset mortars contain various chemical additives to enhance workability, flexibility, and bonding strength, thus expanding the range of application. Water-mixed thinsets consist of powdered sand and cement. They are available with or without powdered latex and acrylic additives and are mixed onsite with water. Latex and acrylic thinsets consist of powdered sand and cement mixed with liquid latexes and acrylics instead of water. They have higher bond and compressive strength and improved flexibility compared to water-mixed thinsets. Epoxy thinsets develop bonds more quickly than other thinsets. The epoxies emit noxious fumes while curing and these fumes can be absorbed by porous surfaces. The use of epoxies is almost always unnecessary in residential construction. If epoxies are used, workers should wear protective vapor respirators during application and the space should be continuously aired out until all fumes have dissipated. The additive ingredients used in these thinset mixtures are proprietary and not disclosed on the label. When selecting a thinset product, choose one that can do the job at hand with the smallest amount of chemical additives and the least odor.

Thinsets Without Synthetic Additives

The following water-mixed thinsets are available without synthetic additives. They gain their strength through the use of high-quality Portland cement, but are generally considered to be less flexible and more prone to cracking than thinsets with latex additives. They may be used successfully over clean concrete slabs, properly supported cementitious boards, and mortar beds.

• C-Cure FloorMix 900, Thinset 911 (dual purpose), andWallMix9oi: The “economy” line of C-Cure mortars, which contain no additives other than mineral salts

• Laticrete Additive Free Thinset

Low-О dor Thin sets with Vinyl Polymer Additives

The following water-mixed thinsets contain vinyl polymers, which give them greater strength and range of application. They have very little odor and are virtually odorless once cured. However, anyone with sensitivities to vinyl polymer additives is advised to test these products prior to using them.

• C-Cure MultiCure 905: A latex-enhanced, dry-set mortar with added bonding strength and flexibility for use over cementitious and plywood substrates

• C-Cure PermaBond 902: A dry-set mortar with Portland cement, sand, and additives for use over cementitious substrates

Leave a reply