CHIMNEY FLASHING

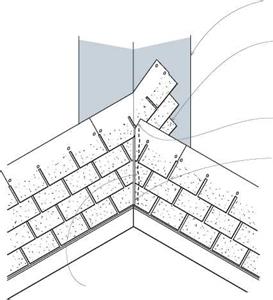

Chimneys must be counterflashed(see p. 74). The upper pieces of counterflashing are usually tucked into chimney mortar joints and made to overhang various pieces of base flashing, which are nailed to the roof deck. Counterflashing and base pieces overlap but aren’t physically joined, so they can move independently yet still repel water. (This independence is necessary because houses and chimneys settle at different rates, causing single-piece flashing to tear and leak.)

![]()

![]()

Urethane caulk under closed-cut shingle edges

There are two kinds of closed valleys: woven and closed-cut. Woven valleys offer better protection from weath er but take longer to install. Cld-cU-cut valleys are faster but are pnly one-nhingle-layer thick in the valley center. When shingling closed valleys, it’s sometimes necessary to add a shorteked shingle yo tne course before yo c reach the val ley, so that yeu nac run a fullshinglh aceoss the valley.

36-in.-wide felt paper or peel-and-stick WSU membrane

Overlapping shingles extend 12 in. past valley center.

No nails within 6 in. of valley center

Replace counterflashing and base flashing when reroofing. To avoid damaging the chimney, use the gentlest possible method to remove counterflashing. If mortar is weak and crumbling, you may be able to pull the flashing out by hand; in that case, repoint the mortar before replacing counterflashing. If the mortar is sound and the counterflashing firmly lodged, try using either a cold chisel or a carbide-tipped bit in a pneumatic air chisel to cut out the flashing and as little of the mortar as possible.

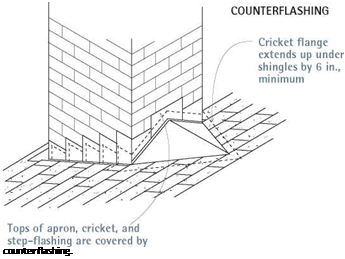

You need to remove base flashing because you’ll be stripping the roofing and building paper at the same time. Base flashing has several components: a continuous sheet-metal apron across the chimney’s downslope face, L-shaped stepflashing running up both sides, and (when the chimney sits below the roof ridge) a cricket (or saddle) running across the upslope face. A cricket is sloped like a tent roof to deflect water around

the chimney. Use a claw hammer, a flat bar, or a cat’s paw to pry up old base flashing. Then hammer down any nails you can’t pull.

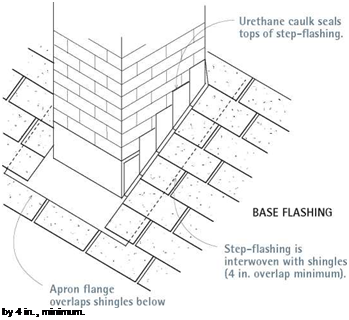

Reattach base flashings first. As shingles butt against the chimney’s downslope face, place the apron over them. The apron’s bottom flange should overlap shingles at least 4 in.; its upper flange should run at least 12 in. up the face of the chimney. Prefabricated aprons usually have “ears” that wrap around chimney corners and are nailed to the deck sheathing. As shingles progress up both sides of the chimney, they overlap the bottoms of L-shaped pieces of step-flashing.

Keep nails as far back from the flashing crease as possible. Use a single nail to nail down each piece of step-flashing and the shingle covering it. When shingle courses along both sides of the chimney reach the back (upslope) face of the chimney, the lower flanges of the cricket overlap them.

![]()

ON THE ROOF

ON THE ROOF

You often see TV antennas strapped to chimneys. Terrible idea! Whipped by winds, an antenna stresses the mortar joints and causes leaks.

A chimney is designed to be a freestanding unit that safely carries hot gases out of the house. Don’t ask more of it.

If a self-supporting cricket is fabricated from heavy 20-gauge galvanized steel, predrill the nail holes in the cricket’s lower flange. Nail it down with ring-shank roofing nails spaced every 6 in., down 2 in. from the top edge. Then cover the top edges of the cricket flange with a strip of peel – and-stick bituminous membrane, and overlap that with shingles. Finally, caulk the top edges of apron, step-, and cricket flashings with urethane caulk to seal them to the chimney.

There are several ways to install counterflashing. Counterflashing should overlap the base flashing by 4 in. Traditionally, a mason used a tuck-pointing chisel to remove chimney mortar to a depth of 112 in. and then inserted a folded lip of counterflashing into the mortar joint. The joint was then packed with strips of lead to hold the flashing in place, followed by fresh mortar applied with a striking tool (also known as a slick). This method can work well, but you need to be careful not to damage the surrounding bricks. Caulk with urethane caulk once the mortar has set.

Alternatively, you can use an abrasive wheel in a handheld grinder to cut narrower slots in the mortar joints; then insert counterflashing with its lip folded back so sharply that it resembles the barb of a fishing hook. This barbed lip friction – fits tightly into the slot, so mortar is unnecessary.

|

The transition step-flashing that turns the corner on a dormer sidewall is complex and inclined to leak, so have it prefabricated by a sheet-metal shop. Seal the top of the step-flashing with 9-in.- wide peel-and-stick membrane, and then overlap that with housewrap before covering it with siding. |

Instead, fill the slot with urethane caulk, which adheres well and seals out water.

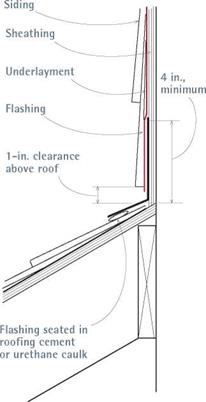

Where roof sections abut other roofs or walls, there are various ways to flash but only one underlying principle: Allow water to run downhill freely.

Where a shed roof abuts a wall, you’ll need to open up the wall or remove siding nails so you can slide the upper leg of the flashing up at least 4 in., under both underlayment and siding—8 in. in snow country. The lower leg of the flashing goes over the uppermost course of shingles on the shed roof. Secure flashing with gasketed roofing nails 2 in. from its lower edge. Stop the siding at least 1 in. above the shingles of the shed roof.

Where a gable-end addition abuts a vertical sidewall, install step-flashing on both sides of the gable. Fashion L-shaped step-flashing by folding in half 5-in. by 10-in. pieces of sheet metal; alternate pieces of flashing and shingles, as you would chimney step-flashing. Again, you’ll need to pull siding nails or cut back the siding to fit the upper legs of the flashing up under wall underlayment and siding. Place nails as far as

Flashing a Shed Roof That Abuts a House Wall

|

|

possible from the flashing folds. Use two nails to attach each piece of step-flashing: one nail (into the sidewall) 1 in. from the top edge of the upper leg and the other nail through the bottom leg and the shingle overlapping it. Apply urethane caulk under any flashing legs or shingle edges that don’t lie flat.

Leave a reply