Techniques ADJUSTING THE MUDSILL TO FIX FOUNDATION WALLS

But here’s some good news: If von know how far off it is, yon can usually make the appropriate corrections when installing the sills (see the sidebar on the facing page). It’s worth it to make the sills as straight, parallel, square, and level as possible. Otherwise, the mistakes made at this preliminary stage tend to become even more troublesome further down the line. Here’s how to check the foundation:

|

|

|

STRAIGHT. Check the walls for straightness bv stretching a dry line (string) from comer to corner. At this point, you just need to knowhow straight the top outside edge of the foundation is, because you’ll be measuring in from this edge to locate the sill.

PARALLEL. Measure across the walls at both ends and in the middle. All three measurements should be the same. 1 use ‘/ in. over 20 ft. as the tolerance limit for parallel.

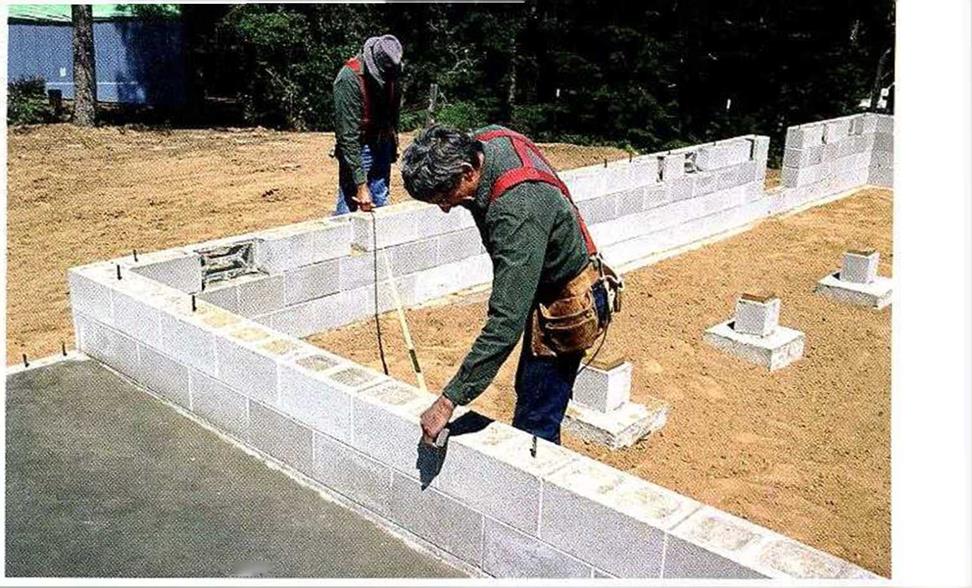

SQUARE. Plus or minus lA in. over 20 ft. is the tolerance that I use for square walls. You can check any rectangular foundation for square simply by comparing the diagonal measurements, which should be equal. When that isn’t possible, use the 6-8-10 rule to check for square corners. Measure 6 ft. in from a corner on one side and 8 ft. on the other side (see the photo above). Then measure between those two points. If the corner is square, the

|

|

|

POSITIONING SILLS ON THE FOUNDATION

ABC

Sill plates can be set flush with the edge of the foundation (A) and the siding nailed directly to the walls. When sheathing the house frame with OSB or plywood, though, hold in the sill plates l/z in. (B). When using rigid foam to insulate a basement or a crawl space (C), position the plates so that the outside face of the sheathing is in plane with the outside face of the foam.

hypotenuse of the triangle should be 10 ft. For smaller buildings, 3 ft. on one side and 4 ft. on the other should yield a 5-ft. hypotenuse. On a large building, use measurements of 12 ft.,

16 ft., and 20 ft.

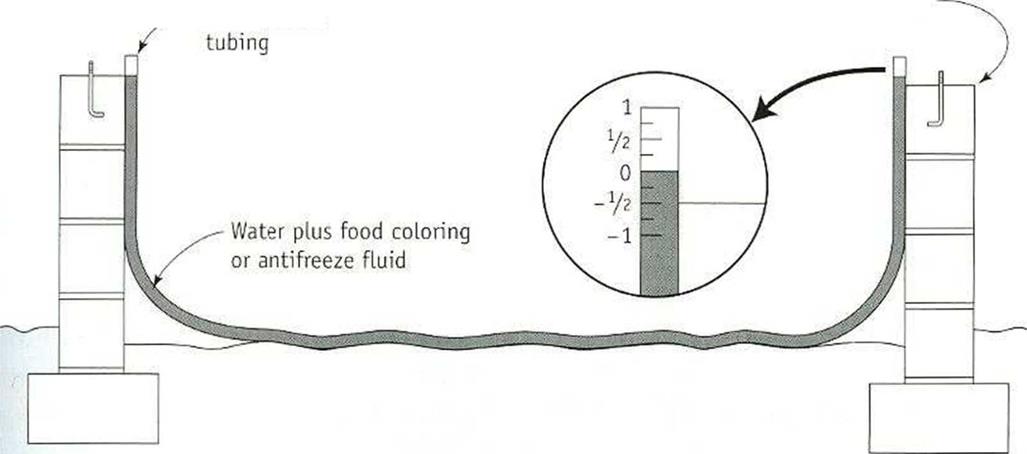

LEVEL. 1 like to check a foundation for level with a builders level (especially one with a laser beam) set on a tripod. If you don’t have one of these available, an inexpensive water level will work fine (see the illustration on p. 33). The walls should be level to within Vi in. over 20 ft.

Depending on what you find after measuring the foundation as described above, you mav

4 4

need to adjust the sills position using some of the techniques explained in the sidebar on

p. 34. The sill plates are often bolted flush to the outside of the foundation, but there are variations vou may want to consider (see the illustration above). For example, when the walls will he sheathed with З-in. plywood or OSB, it’s best to hold the plates V: in. inside the foundation. This puts the sheathing (lush with the foundation and allows the siding to lap down over the concrete.

The sills must be installed along snapped layout lines on lop of the foundation walls. (If you’re building on a slab, the layout lines will be on top of the slab.) The lines identify where the inside edge of the sill will fit.

Taking the width of the sill lumber into account (3V: in. for a 2×4 sill, 3/ in. for a 2×6), snap chalklines around the perimeter to indicate the inside edge of the sill (see the photo on p. 34). Make slight adjustment in the posi

tions of the chalklines, if necessary, so that the sill is straight, square, and parallel.

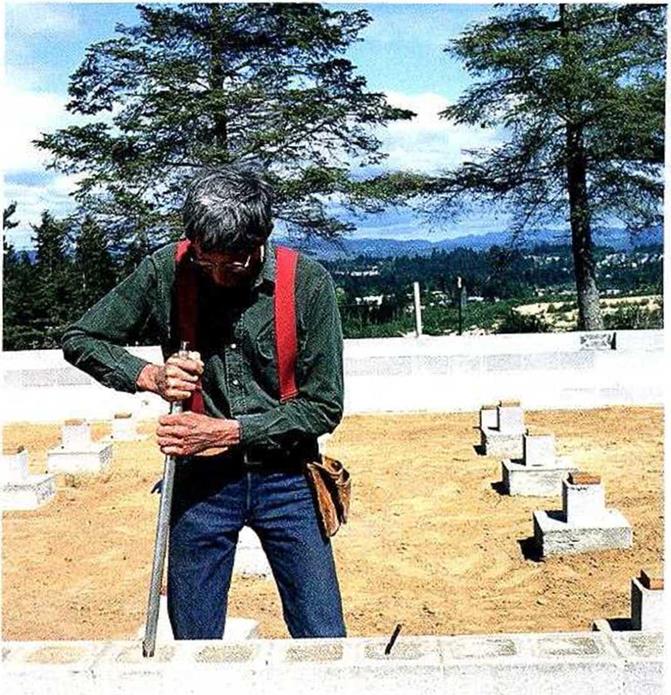

Anchor holts sometimes come out of the foundation at odd angles. You can straighten bent bolts with a length of pipe, as shown in the photo at right. Then set long, straight, pressure-treated sill hoards in place for marking and drilling. You can use a square and a tape measure to lay out the bolt hole locations on the sills, but it’s a lot faster to mark the hole locations with a boll marker (see the photo below). You can make a bolt marker or buy a ready-made version (see the illustration on p. 58 and Resources on p. 278). To use this layout tool, place each plate directly on the inside of the chalkline.

Once the bolt locations are marked, set the sill plates on blocks of wood or sawhorses and drill the holes. Use a T-in. bit to make holes for Tin. bolts. For X-in. bolts, use a /Tin. bit.

Once the bolt locations are marked, set the sill plates on blocks of wood or sawhorses and drill the holes. Use a T-in. bit to make holes for Tin. bolts. For X-in. bolts, use a /Tin. bit.

A LONG PIPE STRAIGHTENS A SHORT BOLT. A length of l-in.-dia. pipe straightens any bolts that may have been bent during (or since) the foundation pour. [Photo Roger Turk.]

A LONG PIPE STRAIGHTENS A SHORT BOLT. A length of l-in.-dia. pipe straightens any bolts that may have been bent during (or since) the foundation pour. [Photo Roger Turk.]

A BOLT MARKER COMES IN HANDY. Use a bolt marker to transfer the bolt locations to the sills so you can drill the bolt holes accurately. [Photo by Roe A. Osborn, courtesy Fine Homebuilding magazine. The Tciinton Press, Inc.]

Leave a reply