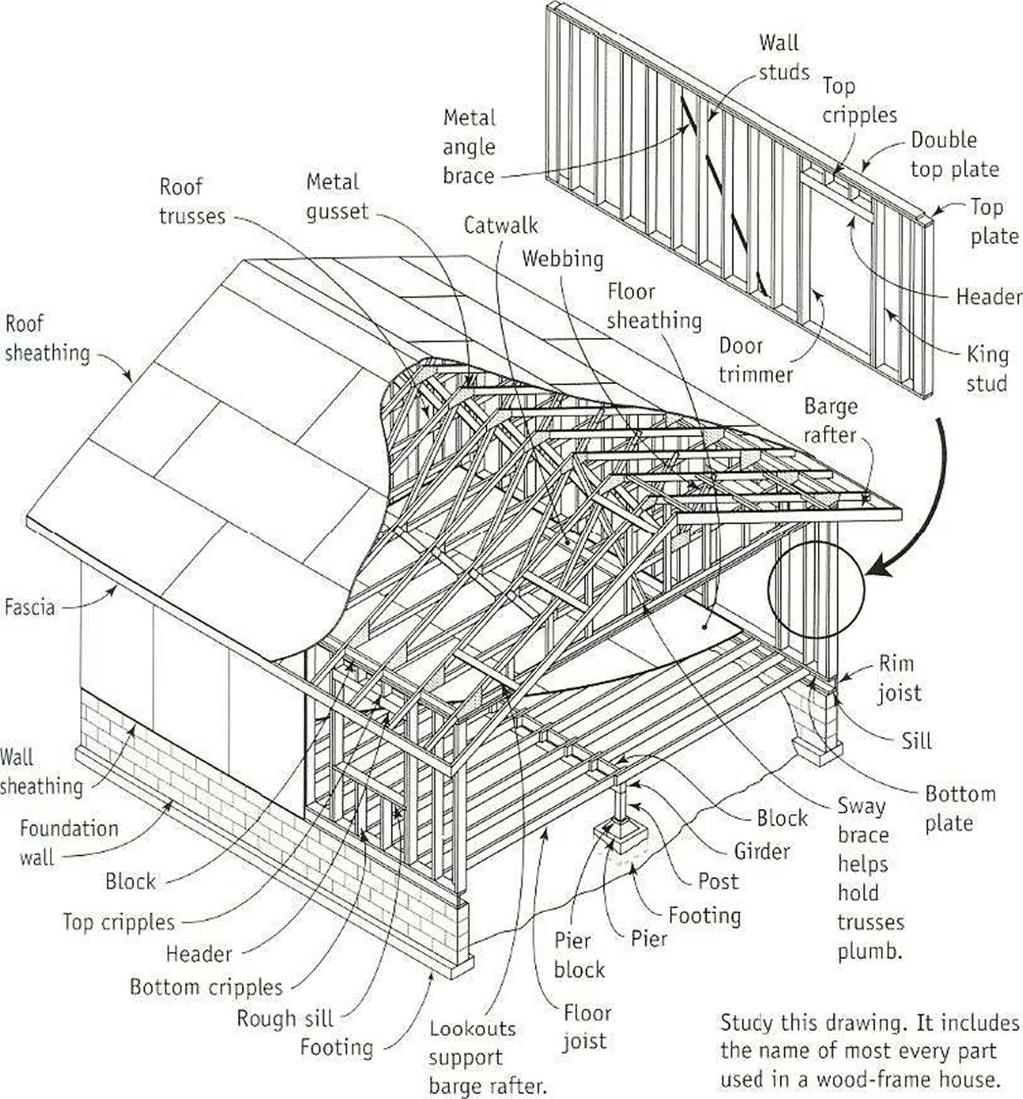

The Parts of a House

When vou decide to build a house, there’s a

/

whole new vocabulary you have to master. Every part of a house has a name and, ns with most endeavors, learning the lingc will take you a long way toward getting the job done. There are plenty of terms that intuitively make sense, such as header, footing, cladding, brace, and sheathing. In other cases, you’ll find that some parts have several names. The illustration on the facing page, combined with the definitions on the following pages, will give you a good basic working vocabulary that we’ll build on in later chapters.

These are generally pressure-treated (PT) 2x4s or 2x6s that are bolted to the concrete foundation and support the floor joists.

Posts are vertical supports for horizontal pieces, which are called girders or beams. These major horizontal members support floor joists. Posts that sit on concrete piers are often made of PI’ wood.

the entire house, running from one outside sill, across any interior girders, to the other outside sill. Most often thev are made from 2x-dimension lumber (such as 2x8s, 2×1 Os, or 2x12s) or from manufactured, wooden I-beam joists.

Typically spaced 16 in. or 24 in. o. c., joists are installed parallel to each other and support the subfloor and rough plumbing. They span

Floors are usually sheathed with %-in.- or M-in.-thick, 4-fl. by 8-ft. sheets of tongue-and – groove plywood or oriented strand board

![]()

![]()

![]()

![]()

![]() (OSB). Better sheets have their edges treated with paint to inhibit moisture absorption in wet weather.

(OSB). Better sheets have their edges treated with paint to inhibit moisture absorption in wet weather.

These are the 2×4 or 2×6 horizontal members that hold together the parts of a wall. Each wall has three plates—one on the bottom and two on the top. The two uppermost plates are called the top plate and the double top (or cap) plate. When framing on a concrete slab, the bottom plate is made of PT wood.

Studs are the vertical wall members nailed to the plates, and they are typically spaced either 16 in. or 24 in. o. c. The standard, precut stud

length in many parts of the country is 924 in. That stud, along with three 114-in.-thick wall plates, creates a framed wall that is 96% in. high. That leaves room for ’/-in. or /-in. dry – wall on the ceiling and full 8-ft. sheets on the walls. In addition lo solid 2x lumber, vou may also encounter finger-jointed studs, which are manufactured from shorter pieces of wood glued end to end. Increasingly, houses are being built with metal studs.

Headers, trimmers, and cripples

The weight from above a window or door opening is transferred around the hole by a header nailed horizontally between studs. Trimmers nailed to the studs at both ends of the header support the header. Cripples, or jack studs, extend from the top of a header to the top plate, as well as from the bottom plate to the underside of rough windowsills.

Each of these factory-made assemblies typically consists of a bottom chord (or joist chord), a top chord (rafters or rafter chords), and interior webbing. Trusses areoflen engineered to carrv the entire weight of a roofs load, transferring it to the exterior walls. That load can be considerable in snowy parts of the country. Trusses allow roof construction to be

4

done quickly and easily. Most trusses for residential construction are spaced 24 in. o. c.

These terms are often used interchangeably,

v «

but a gutter board is technically distinct from a fascia board. Both parts are installed over the ends of the rafter tails. Л gutter board is nailed directly to the rafter tails, and it is covered by aluminum or vinyl cladding or by a fascia board that serves as the finished exteriors trim surface, for more details, see chapter 6.

|

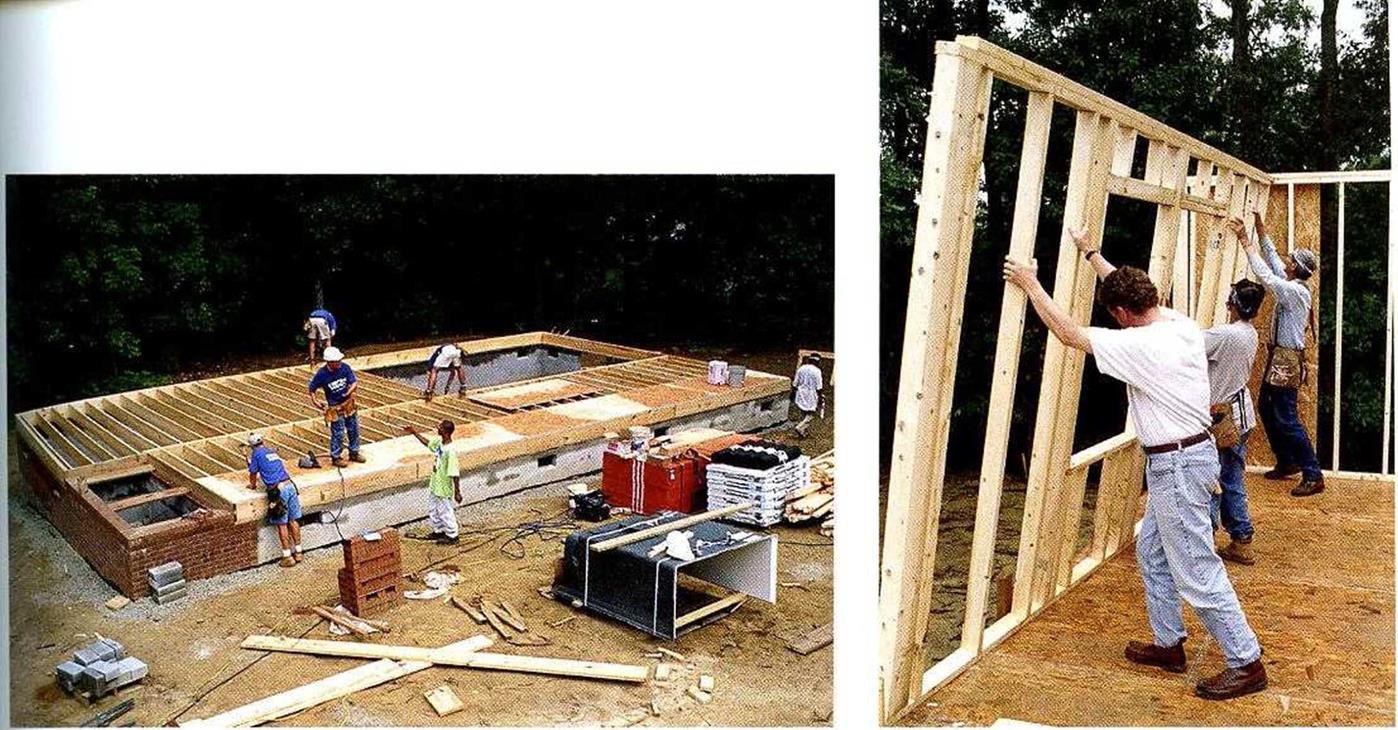

Roofs and walls arc usually sheathed with И-in.- or M-in.-thick OSB. In some parts of the country, exterior walls, along with their gable trusses, arc sheathed before they are raised upright.

Housewrap or fell paper is placed under siding and shingles to prevent wind and water from entering stud cavities or the attic.

Construction adhesives, caulk, and other sealants are ever present on job sites. Most of those products come in cylindrical cartridges that fit inside a caulking gun, which is used to apply the caulk or sealant. Construction adhesives can be used to bond different materials together—floor sheathing to floor joists, for example. To prevent water leakage, caulks are used to seal around windows and doorframes, at siding joints, and where a bathtub meets the floor. They can be used under wall plates and around pipe holes to block out cold air. Gaps between baseboards and walls or door casings can be filled with caulk before painting.

Construction adhesives, caulk, and other sealants are ever present on job sites. Most of those products come in cylindrical cartridges that fit inside a caulking gun, which is used to apply the caulk or sealant. Construction adhesives can be used to bond different materials together—floor sheathing to floor joists, for example. To prevent water leakage, caulks are used to seal around windows and doorframes, at siding joints, and where a bathtub meets the floor. They can be used under wall plates and around pipe holes to block out cold air. Gaps between baseboards and walls or door casings can be filled with caulk before painting.

Nails

The most commonlv used framing nails are 8d (the “d" stands for “penny”) and I6d sinkers, or vinvl-coated nails. The vinvl coat – ing makes the nails drive easier and hole better, but don’t hold them in your mouth. In wet areas or near the ocean, use hot-dipped galvanized or stainless-steel nails.

Screws are typically described by head type (main types include Hat, round, pan, and hex); length (given in inches); gauge, or shank, diameter (usually between *1 and 10); and typical use (drmall, wood, sheet metal, and so on). Although popular for general-purpose use, drvwall screws aren’t strong enough to support heavy loads, such as wall cabinets.

Screws

Drvwall screws are the most universally used

4 4

screws in house construction. But thanks to the popularity of cordless drill-drivers, all kinds of screws are now being used to build houses. Corrosion-resistant screws are available for deck construction and other outdooi

Other fasteners

Toggle bolts, molly bolts, hollow-wall anchors, and other fasteners are used to help secure items, such as wire shelving to drvwall panels. When something must be fastened to a masonry surla. ee, masonry expansion shields and bolts can be used.

applications. Other types of screws are used to install cabinets, built-ins, and hardware.

Materials DEALING WITH SUPPLIERS AND SCHEDULING DELIVERIES

ESTIMATING LUMBER AND MATERIALS for a small, affordable house is fairly simple, but it does take some experience to get it right. If you are building a Habitat house, you can call or e-mail affiliates and ask them to share their lists with you (check the Habitat Web site for the affiliate in your area). You can also take a set of plans to a local supplier. Most building-supply outlets will create a materials list and give you a bid on what everything will cost. Always get bids from more than one supplier. Just make sure every supplier understands the type and grade of each item.

If you don’t make your own list, take the opportunity to inspect the plans closely. Get acquainted with the house and all its parts before you start. Remember that a lumber list is only an estimate of material that will be needed for a particular job. You may need to order a few more items as you build, or

you may need to send some materials back to the supplier. Find out ahead of time whether your suppliers charge a restocking fee for returned materials.

Most builders have materials delivered as needed, rather than all at once. You should do the same. That way, you won’t have to worry as much about storage problems. Also, ask your supplier to stack the lumber load in the order in which it will be used.

Some materials (especially trim, doors, and unpainted siding) should be stored indoors. When storing material outside, set it on blocks above the ground and cover it with plastic to keep it dry. Be specific about where you want the lumber company to drop the wood, and pick a level, accessible location close to where it will be used. Hauling lumber by hand from any distance is hard, time – consuming work.

|

Leave a reply