Other Alternative Building Systes

Although straw has been an important component of natural building for centuries, straw bale is a relatively new form of alternative construction that appears to be an innovation of the early settlers of the Nebraska plains, where unsuitable soils and a scarcity of wood made necessity the mother of invention. The high insulative value of straw bale (between R-33 and R-57, depending on the type of bale and the testing facility) and the aesthetics of the thick walls have quickly made it a popular alternative building material.

Because much of the straw grown in the United States is heavily sprayed with pesticides, we recommend looking for straw that

|

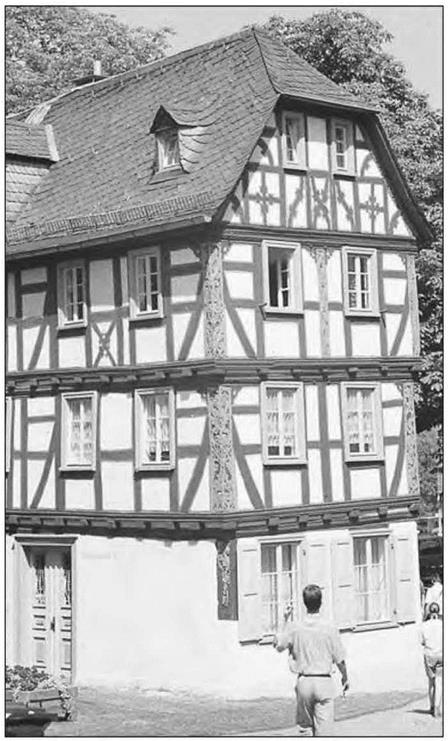

One of many 800 year old structures in Germany. Composed of timber frame and earthen and straw wall materials it stands as a testimonial to the beauty and longevity of natural building materials. Photo: Robert Laporte. |

has been organically grown. The Last Straw, listed in the bibliography at the end of this chapter, has published a list of organic straw sources.

Because cellulose is aperfect food for mold, bales of straw often contain mold. This means that it is very important with straw bale building to incorporate rigorous water and moisture management strategies into the design. If the walls are allowed to breathe — that is, if

they are not covered with impermeable membranes that will trap any moisture in the wall — in theory the bales will always remain dry enough so that mold will not be a problem. Using earth-based instead of cement-based plasters on interior walls will help keep water away from the bales and allow them to dry out more readily when they do get wet. On the exterior of the building, earth-based plasters that are augmented to prevent water penetration may prove more desirable from a moisture movement standpoint than cement-based plasters, which are less flexible, tend to crack more, and allow less vapor diffusion. Should water become trapped in the wall through roof failure, plumbing leaks, poor drainage, or other building systems failures, mold can become a problem.

Many techniques have evolved for straw

bale construction. Building permit approval is greatly simplified when structures are nonload-bearing and most straw bale construction relies on a variety of structural systems, including exposed and buried post and beam, steel posts, and poured or masonry concrete piers. Load-bearing straw bale examples have been built in Colorado, Arizona, and Canada. Several jurisdictions have adopted straw bale codes, including New Mexico and California; Pima County and Guadalupe, Arizona; Austin, Texas; Boulder and Cortez, Colorado; and McCook, Nebraska. Nevada has a legislative mandate to ensure that local jurisdictions develop building codes allowing straw bale construction. While some jurisdictions permit load-bearing straw bale construction, others permit straw bale only as a non-load-bearing wall system.

![]()

![]()

METAL PP-lf Є03Є FA&=lA

METAL PP-lf Є03Є FA&=lA

pXpe&EP №=ЇЧ^

2” РАЄШ 1КЭД/ТО»)

4.CCAT JTUCct?

ptNNtNe» Q^VCLS

MOlSTUfF Е^ШЄР.’ A*4 SILL PIATE5 WINTER FBO0RN6

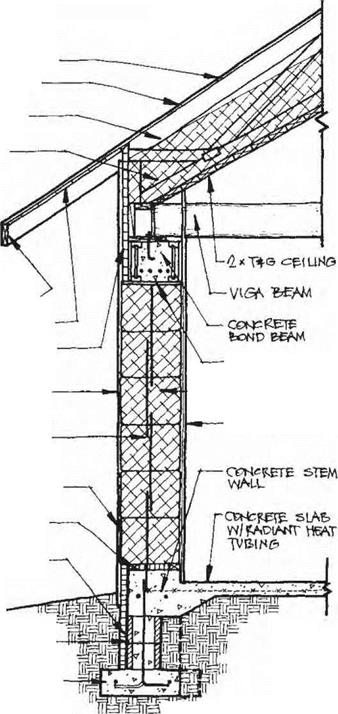

Section through pumicecrete wall.

In this method, 14- to 24-inch-thick walls are created by mixing pumice, a very porous volcanic rock, with a light, soupy concrete. The mixture is poured into formwork. The resulting walls have both thermal mass and a high insulation value, and are ready to accept plaster without further preparation. When used with a concrete bond beam at the top, the walls are load bearing. In Europe, pumice and other naturally occurring lightweight volcanic aggregates have been used with mud in place of the concrete. However, these walls are not used in a load-bearing situation.

Because of the simplicity of this system and the absence of organic matter in the wall construction, pumice-crete is very suitable for persons with chemical sensitivity, who are often also highly sensitive to wood terpenes, mold, and pesticides that may be found in small quantities in other building materials. Since the wall uses cement, the rules for concrete formwork and cement composition, outlined in Division 3, must be followed.

Pumice can be radioactive. Samples should be tested with a Geiger counter to be sure they are free of radioactive material. (Refer to the section on radiation in Division 13 for testing

methods.) Because pumice is highly porous, it can readily absorb odors and it is prudent to specify that pumice be free of acquired odors when it arrives onsite and protected onsite and in place from pollution sources. Once the walls are plastered, this should no longer be of concern.

To help stabilize indoor humidity levels and create further thermal mass storage capacity, clay-based plasters can be applied to interior surfaces and will adhere well without the use of lathing.

Leave a reply