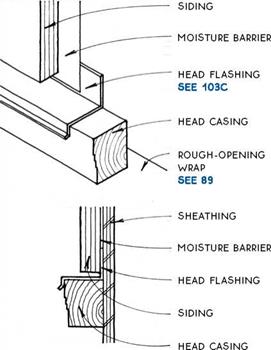

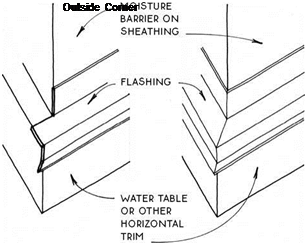

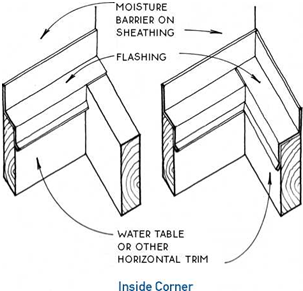

WALL FLASHING

|

|

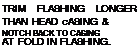

|

|

|

|

![]()

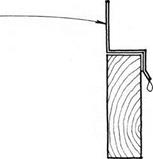

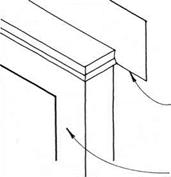

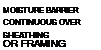

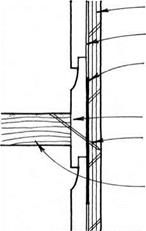

TWO MORE practical solutions ARE TO cut THE FLASHING FLuSH WITH THE cASING, OR, BETTER, TO TRIM & FOLD THE FLASHING ON SITE, AS SHOWN BELOW.

|

|

|

|

|

|

|

|

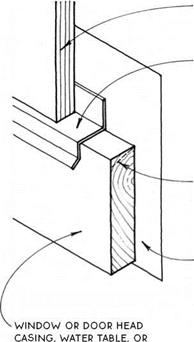

SIDING PANEL

![]()

![]()

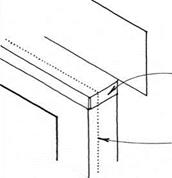

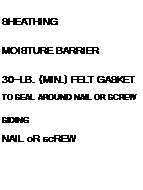

CONTINUOUS HORIZONTAL Z METAL FLASHING WITH 2-IN. (MIN.) OVERLAPS At

CONTINUOUS HORIZONTAL Z METAL FLASHING WITH 2-IN. (MIN.) OVERLAPS At

joints.

siding panel

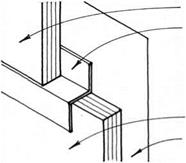

moisture barrier continuous under

Isometric horizontal

siding joint

sheathing (OR stud wall for single-wall construction)

sheathing (OR stud wall for single-wall construction)

continuous moisture barrier

z METAL flashing siding panels

![]()

|

|

|

NOTE

IT is prudent to cover the vertical END OF the flashing with a small piece of moisture barrier OR A DAB OF sealant TO MINIMizE THE POTENTIAL FOR LEAks.

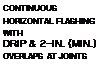

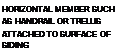

Any horizontal member such as a handrail, a trellis, or a joist that butts into an exterior wall poses an inherently difficult flashing problem at the top edge of the abutting members. Where such a connection is likely to get wet, the best approach is to avoid the problem by supporting the member independent of the wall. A handrail, for example, could be supported by a column near the wall but not touching it. A trellis could be self-supported.

If a horizontal member must be connected to a wall in a location exposed to the weather, two things can be done to protect the structure of the wall. First, do not puncture the surface of the siding with the member, and do everything possible to attach the member to the surface of the siding with a minimum number of fasteners. Second, place an adequate gasket, such as 30-lb. or 90-lb. felt, behind the siding at the location of the attachment. This will help seal nails or screws that pass through the siding to the structure of the wall.

If a horizontal member must be connected to a wall in a location exposed to the weather, two things can be done to protect the structure of the wall. First, do not puncture the surface of the siding with the member, and do everything possible to attach the member to the surface of the siding with a minimum number of fasteners. Second, place an adequate gasket, such as 30-lb. or 90-lb. felt, behind the siding at the location of the attachment. This will help seal nails or screws that pass through the siding to the structure of the wall.

Leave a reply