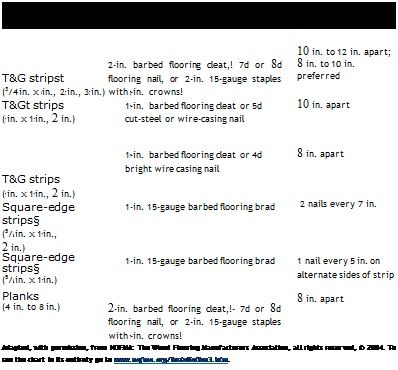

Floor Nailing Schedule*

ing or air-conditioning so indoor conditions will be close to normal (60°F to 70°F) for a week before installing flooring. Open the bundles of wood flooring and allow them to acclimate indoors for 72 hours before installing them.

ing or air-conditioning so indoor conditions will be close to normal (60°F to 70°F) for a week before installing flooring. Open the bundles of wood flooring and allow them to acclimate indoors for 72 hours before installing them.

Use a moisture meter to check interiors if your region has high humidity. Home centers and electronics stores carry reliable, inexpensive meters. Ambient humidity indoors should be 35 percent to 55 percent; if readings are higher, consider installing a dehumidifier. Also check the moisture content (MC) of wood subfloors and flooring, using a moisture meter with probes. Typically, wood flooring’s MC is 6 percent to 10 percent.

The subfloor’s MC should not vary more than 4 percent from that of the flooring’s.

If you’re installing floors over a basement or crawl space, check the humidity of that area, too. If it’s too high, correct any contributing factors before installing wood floors; high humidity also encourages mold. Crawl spaces with dirt floors

should be covered with plastic and sealed to limit moisture and air infiltration, as described in Chapter 14.

Survey subfloors to make sure they’re solid, flat, and clean. If floors are excessively springy, stiffen them by adding blocking between the joists, adding plywood or OSB (oriented strand board) panels over existing subfloors, or sistering new joists to old ones, as described in Chapter 8. In older houses, floors are rarely level; so if they’re solid, it’s more important that they be flat—within 12 in. per 10 ft. Use a rental edging sander or a woodworker’s belt sander with coarse sandpaper to lower high spots; use strips of building paper (15-lb. felt paper rather than rosin paper) or wood shims to build up low spots. In general, masonry floor-leveling compound is too inflexible to use beneath wood flooring because flooring nails will fragment it and board flexion will fracture it.

If you notice protruding nail heads, not enough nails, or squeaky spots, correct these conditions now. Squeaks can usually be silenced by screwing down subflooring to joists near the squeak or by nailing it down with ring-shank or spiral nails. Vacuum and sweep the floor well. If the floor is over an occasionally damp basement or crawl space, staple 15-lb. building paper to the subfloor, overlapping roll seams by 6 in. However, don’t bother with building paper if the subfloor areas are dry or if the floor is on an upper story.

Finally, remove the baseboard molding if you can do so without damaging it. Baseboards hide the expansion gap between the perimeter of the flooring and the base of the wall. At the very least, install a piece of quarter-round shoe molding to cover the gap if you can’t remove the baseboards. If door casings are already installed, undercut (trim the bottoms of) each side jamb, by the thickness of the flooring; an undercut saw is specially designed for this task. Remove doorway thresholds if they’re nailed down. But if they’re glued down or set in mortar, simply butt the flooring to them.

Sawdust or debris trapped under a board can mean uneven, loose, or squeaky floors later on, so be obsessive about keeping subfloors clean as you install flooring.

Installation tools include safety glasses, hearing protection, kneepads, radial-arm saw or small table saw, hammer, nail set, tape measure, chalkline, flat pry bar to remove trim, large flat-bladed screwdriver to draw board edges tight to each other, flooring mallet, and a manual or pneumatic

flooring nailer. For the little bit of face-nailing to be done, use a pneumatic finish nailer; if you haven’t got one, use a Иб-in. bit to predrill holes for the face nails. You’ll need white glue to secure floorboards under toekicks and in other odd spaces where it’s difficult to reach with any nailer. Finally, rent a shop vacuum if you don’t own one. And be sure to have a good-quality broom and a dustpan.

Pneumatic flooring nailers are more expensive than manual nailers, but they don’t depend on your strength to drive flooring nails to the correct depth. Nailers aren’t foolproof, though. Take a sample of the flooring to the rental company to ensure that the pneumatic nailer will correctly engage the flooring edge profile. That is, the tool may need an adapter-fitting or – plate to avoid damaging the boards’ tongues. On-site at the start of the job, calibrate the nailer’s pressure by nailing a "practice row” of flooring to the subfloor. Typically, pneumatic nailers are set at 70 psi (pounds per square inch); adjust the pressure up or down till the tool sets nails correctly, as shown in "How Deep Can You Sand?,” on p. 488. Once the setting is correct, pull up the practice row.

Leave a reply