PIPE THREADS

Pipe threads come in different styles. Some are compatible, and others are not. You could encounter straight pipe threads, tapered pipe threads, or firehose coupling straight threads. To understand the types of pipe and hose threads, let me give you some illustrations to consider. The tables in Figures 11.11, 11.12, and 11.13 show you how many threads per inch to expect with different thread types. Fire hose threads are not compatible with any other type of threads. The same is true for garden hose threads. But, some threads are compatible with other types. If you have a female NPT thread pattern, it is compatible with male threads of an NPT type. The proper sealant to mate these threads is a thread seal. American Standard Straight Pipe (NPSM) threads on female threads can be mated to either NPSM male threads or NPT male threads. To seal such a connection, a washer seal should be used.

|

FIGURE 11.11 ■ Threads per inch for national standards. |

|

FIGURE 11.12 ■ Threads per inch for American Standard Straight Pipe. |

|

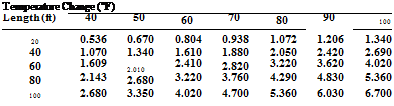

FIGURE 11.13 ■ Threads per inch for garden hose. |

Female threads that are NPSH can be coupled with male threads of NPSH, NPSM, or NPT types. In any of these cases, a washer seal should be used. Threads of a garden hose type are mated with a washer seal. But, what happens when you are trying to find compatible matches for a male thread pattern? If you have an NPT male thread, it can be mated to NPT, NPSM, or NPSH threads. When NPT is mated to NPT, a thread sealant should be used. Washer seals are used to mate NPSM or NPSH female threads to male NPT threads. A male NPSM thread can mate with female thread types of NPSM or NPSH. A washer seal should be used for these connections. Garden hose threads, whether male or female, can only be coupled to garden hose threads, and this is done with a washer seal.

Metric sizes are common in many places of the world. Plumbers in the United States still work primarily with customary measurements in terms of inches. However, you may find times when metric equivalents are useful. For this reason, I’m providing Figure 11.2

Metric sizes are common in many places of the world. Plumbers in the United States still work primarily with customary measurements in terms of inches. However, you may find times when metric equivalents are useful. For this reason, I’m providing Figure 11.2 There are two basic types of showers for handicap use. Wide shower enclosures are one type, and square shower enclosures are the other. Shower stalls may be made on site or purchased as pre-fab units (Fig. 10.12). When a wide shower enclosure is used, it must have a minimum width of 60 inches. The depth must be no less than 30 inches. Thresholds are prohibited. Showers of this type must be made to allow wheelchairs to enter the enclosure. Shower valves must be mounted on the back wall. The minimum distance for the valve

There are two basic types of showers for handicap use. Wide shower enclosures are one type, and square shower enclosures are the other. Shower stalls may be made on site or purchased as pre-fab units (Fig. 10.12). When a wide shower enclosure is used, it must have a minimum width of 60 inches. The depth must be no less than 30 inches. Thresholds are prohibited. Showers of this type must be made to allow wheelchairs to enter the enclosure. Shower valves must be mounted on the back wall. The minimum distance for the valve

The seat must be mounted along the entire length of the shower. Seat height is established as a minimum of 17 inches above the shower floor, with a maximum height of 19 inches. Grab bars must be installed to extend from the edge of the seat around the sidewall opposite the seat. These bars must be at least 33 inches above the shower floor, and not more than 36 inches above the floor. A shower valve must be mounted on the sidewall opposite the seat. The minimum height

The seat must be mounted along the entire length of the shower. Seat height is established as a minimum of 17 inches above the shower floor, with a maximum height of 19 inches. Grab bars must be installed to extend from the edge of the seat around the sidewall opposite the seat. These bars must be at least 33 inches above the shower floor, and not more than 36 inches above the floor. A shower valve must be mounted on the sidewall opposite the seat. The minimum height