An electronic stud finder will locate studs quickly and accurately. But if you don’t have one, there are other methods you can use. Look on the floor for keel marks that were used to locate the studs before drywall installation. Electrical-outlet boxes are nailed into studs. Tap gently on the wall and listen for a duller sound when you tap over a stud. Or drive nails behind the cabinet to locate a stud. When one stud is found, other studs should be 16 in. or 24 in. from it. Once the studs are found, mark their locations inside the cabinets on the mounting rail. Predrill screw holes in the cabinet mounting rail, set the cabinet in place, and drive a screw into each stud. If the screw misses the stud, check again for its location until you get it right. And feel free to use a few extra screws in wall cabinets. Just make sure they go into studs.

Many types of countertops are available these days, but the most common type of affordable countertop is plastic laminate applied over particleboard or MDF. Laminate countertops come in many colors and styles. Remember if you choose this type of countertop that scratches show up more on dark surfaces than on lighter ones. Also, be aware that very hot pans can leave burn marks on laminate countertops. Sometimes, a countertop is also needed in a bathroom, but often the bath vanity comes with a countertop and a sink already attached.

A countertop ends where it meets a wall or stove and extends 1 in. or so beyond the end of the last cabinet. When I’m ready to install a countertop, I go to a supplier, pick a color, and give the clerk the exact measurements of the base cabinets. I prefer the style of laminate countertop that comes with a backsplash. If you provide the size and location of the sink, the supplier can cut the hole for it, often at no additional cost (see the top photo on p. 257). Otherwise, a hole can be cut on the job site with a jigsaw or a reciprocating saw (sabersaw) equipped with a fine-tooth blade. Just follow the directions that come with the sink. Put some duct tape on the base of the saw to keep it from scratching the laminate surface.

In many Habitat houses, the kitchen layout provides for straight countertop surfaces rather than L-shaped countertops, which are more difficult to install. If you need an L-shaped countertop, the supplier will make the necessary miter cuts and provide special hardware for joining countertop sections from underneath. Before joining mitered sections, put waterproof silicone caulk on the two mating edges.

Test-fit each countertop section, placing it on top of the base cabinets and seeing whether the unit fits properly. If the backsplash doesn’t fit tightly against the wall, fill small gaps with silicone caulk after attaching the countertop. If necessary, especially on a crooked or wavy wall,

scribe a line on the backsplash and then use a belt sander to remove material from the back – splash to make it fit against the wall.

ATTACH THE COUNTERTOP WITH SCREWS. Usually, base cabinets are built so the top can be screwed directly to them. For some cabinet and countertop combinations, though, a supplier may advise you to put strips of 1 x material on top of the base cabinets so the countertop nosing won’t prevent cabinet doors and drawers from opening.

Prefinished countertops must be attached with screws from below. Attach the countertop by driving Р/4-in.-long screws up through the 1x mounting blocks installed by the cabinet manufacturer (see the illustration on the facing page). Predrill a screw hole through the mounting blocks, but be very careful not to drill or drive the screws so deeply that you break through the finish surface. It’s easy to strip a screw driven into a countertop’s particleboard or MDF substrate, so don’t try to drive installation screws extra tight. Complete the job by running a neat bead of silicone caulk between the back – splash and the wall.

STEP 6 INSTALL THE BASEBOARD AND CHAIR RAIL

The old house I grew up in had full 1×12 baseboards. In our part of the country, they were called mopboards. In those days, people used big mops to clean their floors with soap and water. The baseboard not only covered the joint between the plaster and the floor but also protected the walls from being banged by the mop.

Today, baseboard trim is made from real or manufactured wood, and there are many styles available. In the last Habitat house we built here on the coast, we used 1×4 baseboards made of preprimed MDF. Once it was installed and painted, it looked great, but it was so solid that you could hardly drive a nail through it by hand.

In other houses, we have used 3-in.-wide trim that’s about 3/8 in. thick at the bottom and slopes up to a slender top edge. The thin edge

In other houses, we have used 3-in.-wide trim that’s about 3/8 in. thick at the bottom and slopes up to a slender top edge. The thin edge

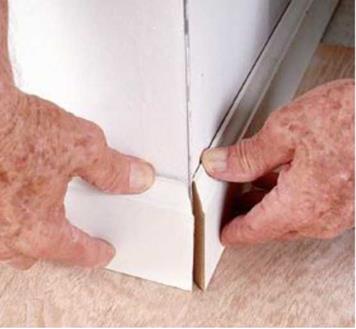

![ATTACHING A COUNTERTOP TO A. BASE CABINET Подпись: Inside baseboard corners are coped. The coped cut fits the profile of the trim piece that runs into the corner. [Photo © The Taunton Press, Inc.]](/img/1312/image822.gif)

makes it harder for dust to collect on the top. Baseboards still cover the joint between the drywall and the floor and keep the wall from getting banged by a vacuum cleaner. Order long stock from the supplier so you can eliminate joints on most walls.

Install the baseboard trim

Before installing baseboards, use a putty knife first to clean any excess joint compound from the corners. Then clearly mark (or re-mark) the location of the studs on the floor. If the gap between the bottom edge of the drywall and the floor is greater than 1 in., take the time to fill it with strips of ‘/i-in.-thick OSB or plywood. Otherwise, the bottom part of the trim can easily be canted inward during installation. If you’ll be nailing the baseboard by hand, protect your knees with a pair of kneepads.

Paint-grade MDF is a material commonly used in baseboard and door trim. It is not advisable to use this material in bathrooms, kitchens, or laundry rooms. MDF absorbs water easily, causing it to expand. It will then have to be replaced.

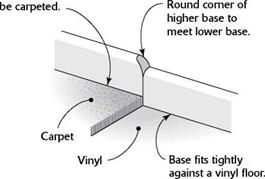

Right-handed people generally prefer to install baseboard counterclockwise (right to left), starting at a door. This makes it easier for righties to cut a coped joint. Lefties tend to install baseboard clockwise for the same reason. Set baseboard right on vinyl or wood flooring, but hold it up about Vi in. if you plan to install carpeting later so that you can slip the carpet under it. When working in rooms that will later be carpeted, use small blocks of OSB as temporary supports under baseboards as you nail them to the wall.

To get my trim skills up to speed, I like to start running baseboard in a closet. Try making a rough plan of each room on scrap paper and record the measured length of each wall. Drywall is often left a bit rough near the floor line, so it’s hard to measure accurately at that point. Hold the tape off the floor a couple of inches to get a more accurate measurement.

This will save you time walking back and forth to the chopsaw with a new measurement each time you want to make a cut.

The first piece right inside the door is measured to length from the door casing to the wall and cut square on each end. Often, that piece is quite short (2 in. or so). If it fits snugly in place, you may not need to nail it. Instead, spread some glue on the back and just press it into position. The next piece of trim will hold the short

|

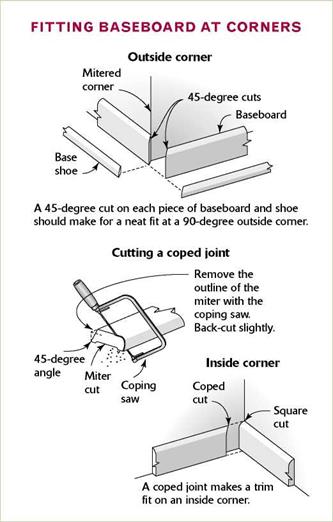

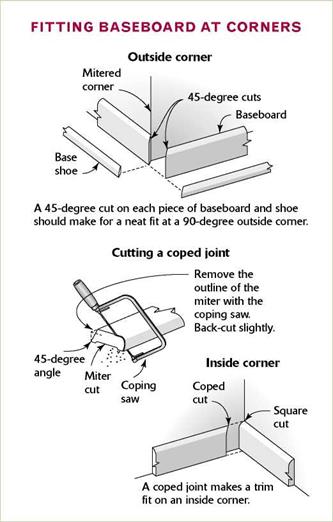

Outside corners are mitered. Two pieces of baseboard cut at 45-degree angles should meet to form a neat, tight 90-degree corner.

|

|

|

MARK THE BASEBOARD AT OUTSIDE CORNERS AND ON LONG WALLS.

I prefer marking trim for outside corners in place rather than determining the length with a measuring tape. Position a piece of trim along the wall. Make a mark where the top of the trim meets the corner. The cut will be the short point of the 45-degree miter. The two mitered pieces of baseboard meet at a corner and make a 90-degree angle (see the photo at left).

If an outside corner is not square, adjust the cut to make the miters fit (see the sidebar on p. 262). A bit of glue on the corner will help hold the joint secure. Drive a 4d nail through the face of one baseboard and into the end of

|

|

|

Pneumatic gun nails are labeled in inches rather than by “d”. So rather than looking for an 8d nail, you need to look for a 2-in. gun nail. These nails are thin with a square point, which allows them to be driven into wood without splitting it.

|

|

|

|

|

|

|

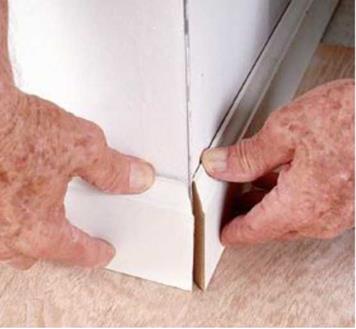

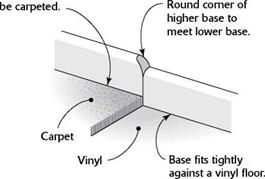

Hold base up 1/2 in. from floor that will

|

|

|

|

|

On a vinyl floor, a base shoe can be nailed at the bottom of the baseboard.

|

|

|

|

|

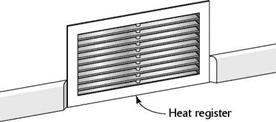

Where baseboard runs into a heat register, cut the baseboard back 15 degrees on both sides to soften the ends.

|

|

![STEP 4 PREPARE FOR THE WORST Подпись: Rather than a lawn, try growing a garden in a few raised beds. Not only will you have veggies and flowers for your family, but there will be plenty to share with your neighbors. [Photo by Don Charles Blom]](/img/1312/image865.gif)

![STEP 4 PREPARE FOR THE WORST Подпись: Leave the lawn cutting to the parks and recreation department.Yards can be made attractive by using bark, chips, and a few native plants. [Photo by Don Charles Blom]](/img/1312/image866.gif)

As a homeowner, you should also know the location of the main electrical circuit box. It contains wires leading to every part of the house and the circuit breakers, which are the switches that control the electricity on individual circuits. Open the box door covering the circuit breakers and make sure the electrical contractor has labeled what each breaker controls. This circuit map should be on the inside of the door. You should be able to identify the separate breakers for the stove, refrigerator, and furnace, as well as lighting and receptacle circuits for different parts of the house. There will also be a large single breaker that completely shuts down the current throughout the house. With well – labeled breakers, you’ll be able to shut off power when you need to do wiring work on a specific switch or outlet.

As a homeowner, you should also know the location of the main electrical circuit box. It contains wires leading to every part of the house and the circuit breakers, which are the switches that control the electricity on individual circuits. Open the box door covering the circuit breakers and make sure the electrical contractor has labeled what each breaker controls. This circuit map should be on the inside of the door. You should be able to identify the separate breakers for the stove, refrigerator, and furnace, as well as lighting and receptacle circuits for different parts of the house. There will also be a large single breaker that completely shuts down the current throughout the house. With well – labeled breakers, you’ll be able to shut off power when you need to do wiring work on a specific switch or outlet.

If an outlet doesn’t work, one of the first things to check is whether it’s a ground-fault circuit interrupter (GFCI) outlet. GFCI protection is required for outdoor receptacles (outlets) and electrical outlets in the kitchen and bathroom—places where the presence of moisture might pose an electrical shock hazard. If overloading or an electrical short is detected, a GFCI circuit breaker will shut down at the main service panel, cutting off power to all outlets on the circuit. GFCI protection can also be provided by a GFCI receptacle that’s wired to other receptacles. Both GFCI devices have test and reset buttons. Find out which type of GFCI protection you have, where the devices are located, and which outlets they control.

If an outlet doesn’t work, one of the first things to check is whether it’s a ground-fault circuit interrupter (GFCI) outlet. GFCI protection is required for outdoor receptacles (outlets) and electrical outlets in the kitchen and bathroom—places where the presence of moisture might pose an electrical shock hazard. If overloading or an electrical short is detected, a GFCI circuit breaker will shut down at the main service panel, cutting off power to all outlets on the circuit. GFCI protection can also be provided by a GFCI receptacle that’s wired to other receptacles. Both GFCI devices have test and reset buttons. Find out which type of GFCI protection you have, where the devices are located, and which outlets they control.![Wood and plastic laminate floorings are very durable Подпись: Install a “floating floor. Both plastic-laminate flooring (shown here) and engineered-wood flooring can be installed without nails. The individual sections of flooring “snap” together in an interlocking joint. The finished floor “floats” on a resilient pad laid over the subfloor. [Photo by Don Charles Blom]](/img/1312/image859.gif)

![STEP 2 SELECT AND INSTALL THE FINISH FLOORING Подпись: Engineered-wood flooring is easy to install. Plied construction, tongue- and-groove joints, and a factory-applied finish make engineered-wood flooring easy to install and very durable. Different plank widths and a wide range of wood species are available. [Photo by Scott Phillips, courtesy Fine Homebuilding magazine © The Taunton Press, Inc.]](/img/1312/image857.gif)

![Install the interior-door hardware Подпись: Bath fixtures can be mounted on a 1x4 and then screwed securely into wall studs. [Photo by Don Charles Blom]](/img/1312/image853.gif)

![Install the interior-door hardware Подпись: Vinyl flooring offers beauty, durability, and easy main-tenance. Available in roll or tile form, vinyl flooring offers all three advantages, making it a wise choice for kitchens. [Photo by Reese Hamilton, courtesy Fine Home-building magazine © The Taunton Press, Inc.]](/img/1312/image855.gif)

![DETAILS Подпись: Find a comfortable seat. A small workbench or even a 5-gal. bucket allows you to sit down when installing latches and locksets. [Photo by Don Charles Blom]](/img/1312/image849.gif) Buy your welcome mat early! To reduce the amount of dirt that gets tracked into a house after new carpeting and vinyl and wood flooring have been installed, set up some sort of dirt-catching mat. Put it by the front door near a sign that says, “Please wipe your feet or remove your shoes.”

Buy your welcome mat early! To reduce the amount of dirt that gets tracked into a house after new carpeting and vinyl and wood flooring have been installed, set up some sort of dirt-catching mat. Put it by the front door near a sign that says, “Please wipe your feet or remove your shoes.”![DETAILS Подпись: Use an easier handle. A lever-type door handle is easier to open than a round knob is, especially for older folks and those with arthritis or carpal-tunnel pain. [Photo © Rex Cauldwell]](/img/1312/image850.gif)

![Add smaller shelves to a closet Подпись: The inside of a closet can be arranged to hold much more than clothes on hangers. A bank of shelves can eliminate the need for a chest of drawers. [Photo by Don Charles Blom]](/img/1312/image839.gif)

[Photo by Roe A. Osborn, courtesy Fine Homebuilding magazine © The Taunton Press, Inc.]

[Photo by Roe A. Osborn, courtesy Fine Homebuilding magazine © The Taunton Press, Inc.] Cut the shelves to fit between the divider and the closet wall, then nail them to the cleats to further secure the divider.

Cut the shelves to fit between the divider and the closet wall, then nail them to the cleats to further secure the divider.

![ATTACHING A COUNTERTOP TO A. BASE CABINET Подпись: Inside baseboard corners are coped. The coped cut fits the profile of the trim piece that runs into the corner. [Photo © The Taunton Press, Inc.]](/img/1312/image822.gif)