Residential furniture is rarely included in the construction contract. The owner will typically select the furniture and have it installed on her or his own or with the guidance of an architect or interior designer. Nevertheless, we are including some guidelines and resources for the selection of healthful furniture because new furnishings can have a major impact on indoor air quality.

Most standard furniture is built like most standard housing. It is mass-produced with little or no thought about the health of the buyer. For those of you who have gone to great effort to create a healthy home, shopping wisely for healthy furnishings is the next logical step. Once again you will find yourself in the role of a pioneer. Most furniture salespeople will not understand what you mean when you speak of healthy furniture. Yet formaldehyde and other chemical levels can soar when new furnishings are brought into the home. Tbe furniture can continue to pollute the environment throughout its life.

As with the production of building ma

terials, there are many broader environmental concerns pertaining to the manufacture of furniture. These include the use of endangered wood species, toxic waste produced at the manufacturing facility, factory workers’ exposure to hazardous chemicals, wasteful packaging, and the exploitation of exporting countries. These factors are discussed in depth in other publications. We will concentrate on health concerns for the homeowner.

Wood Furniture

Most newly constructed wood furniture is actually veneered wood attached to a core of particleboard or plywood. These manufactured sheet goods are often bound with urea – formaldehyde glues, which will outgas for many years. Even so-called solid wood pieces may contain hidden plywood or particleboard components in order to save on production costs. When selecting wood furnishings, keep the following recommendations in mind:

• Purchase solid wood furniture that does

Above: I nterior of Daryl Stanton Residence features solid wood antique furniture, custom made organic cotton and wool upholstered furniture and area rugs. Kitchen has solid wood cabinets and open shelving. Architect: Baker-Laporte Associates; Builder: Econest Building Co. Photo: David Hoptman.

Below: Interior of Baker-Laporte Residence features solid wood furniture — formaldehyde free built-in window seat and custom made cotton uphostery with organic cotton stuffing. Photo: Lisl Dennis.

not make use of veneers or sheetgoods. Hardwoods are preferable because they emit fewer terpenes than softer woods. Numerous farmed hardwoods are available. Old-growth forest need not be destroyed by your furniture selection. Although the initial purchase price for solid wood furniture may be higher, you will be investing in heirloom quality.

• If veneered wood is all your budget will allow, consider sealing all surfaces and edges with one of the low-VOC vapor-barrier sealants listed in Division 9. In addition, consider materials such as wrought iron and glass for tables and wicker or rattan for seating. Examine cane furniture prior to purchase to make sure it is free of mildew and mold.

• Furniture imported from tropical countries is often sprayed with pesticides while in transit. Furniture imported from Europe will meet Ei emissions standards and is often constructed with low-emissions sheetgoods. Look for furniture that meets GreenGuard emissions standards, which are more stringent. This furniture must achieve formaldehyde emission rates of less than 0.05 part per million. Chemically sensitive individuals should test for individual tolerance to these amounts of formaldehyde.

Following are sources for solid wood or low – emissions furniture:

• Casa Natura: Solid wood furniture

• Ikea: Solid wood and veneered wood furnishings sourced from sustainably managed forestry operations and meeting Ei emissions standards

• Pacific Rim: Handcrafted, solid western maple furniture made from wood grown in managed forests in Washington and Oregon

• Pottery Barn: Solid wood furniture

• Smith and Hawken: A variety of sustainably harvested teak and cedar solid wood furniture

• Eco-terric: Green and healthy furnishings for the home

• H3 Finishes for wood furnishings

Durability, not health, is the criterion used by manufacturers when choosing finishes for wood furniture. The majority of commercial wood sealers are solvent-based and will out – gas harmful chemicals. We offer the following suggestions:

• Look for furniture with low-VOC, water – based natural oil or wax finishes.

• Buy unfinished furniture and finish with low-VOC finishes.

• If you purchase furniture with a standard finish, air it out before placing it in your living space.

Upholstery

Most commercially available upholstered furniture is stuffed with synthetic foam or latex. Many foams will initially have a strong odor. They will break down over time and emit fine particles of chemical dust into the air. Polyurethane foams are extremely hazardous when burned. Furniture stuffing can be made with natural ingredients such as wool, natural latex, down, kapok, and organic cotton batting. Although these alternatives are not widely available in readymade form, you may find an upholsterer in your vicinity who is willing to work with you. A hardwood frame made for

a futon, or solid hardwood benches, can be turned into healthy couches with the addition of custom-made pillows. Down and kapok stuffings can be allergens for some people.

Upholstery textiles are often synthetic and treated with toxic chemicals to improve stain resistance. Look for natural, untreated upholstery fabrics such as organic cotton, wool, or silk. AFM Safe-Choice Lock Out can be used on some fabrics to help repel dirt and stains. Materials must be tested for shrink resistance and color fastness prior to application.

Some sources for all-natural upholstered furniture are:

• Cisco Brothers: FSC certified furniture

with water-based glues and environmentally friendly manufacturing processes

• Eco-terric: Green and healthy furnishings for the home, healthy-home consultation, and interior design

• Furnature: Manufacturer of natural, organic furniture line, mattresses, and bedding for people with multiple chemical sensitivities

Window Dressings

Most window dressings are made of synthetic fabrics treated with chemicals to make them wrinkle resistant. The recommended

![]()

Decorative and durable, tile can handle high humidity and heavy use-making it a great choice for kitchens and baths. A little Mexican, a little Moorish, this bathroom is always sunny.

Decorative and durable, tile can handle high humidity and heavy use-making it a great choice for kitchens and baths. A little Mexican, a little Moorish, this bathroom is always sunny.

expensive. Also check on availability. Will specially ordered tile arrive in time to meet your renovation schedule?

expensive. Also check on availability. Will specially ordered tile arrive in time to meet your renovation schedule?

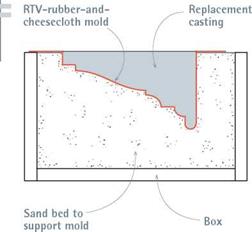

To make the mold, paint on a coat of RTV rubber and allow it to dry. Thereafter, alternate strips of cheesecloth and rubber, allowing each RTV – and-cloth layer to dry before applying the next coat. Three or four layers should give you a mold that’s sturdy enough. When the final coat is dry, peel the RTV mold off the original plaster section, and pour a new casting into the mold.

To make the mold, paint on a coat of RTV rubber and allow it to dry. Thereafter, alternate strips of cheesecloth and rubber, allowing each RTV – and-cloth layer to dry before applying the next coat. Three or four layers should give you a mold that’s sturdy enough. When the final coat is dry, peel the RTV mold off the original plaster section, and pour a new casting into the mold.