Stair configuration

The shape or configuration of a stairway is determined primarily by the circulation patterns of a building and by available space. Virtually any configuration of stairway may be constructed using the standard details of this chapter by merely breaking the stairway into smaller pieces and reassembling them. Several typical configurations that are worthy of note are shown in the drawings that follow; for clarity, these drawings do not show railings.

Straight-run stair—The straight-run stair is the most economical standard stairway from the standpoint of efficiency of floor space taken up by the stairway itself. The straight-run stair works best in two-story buildings.

|

|

The bottom and top steps are separated horizontally from each other by the entire length of the stairway, so that a multistory building with stacked stairways requires circulation space on each floor to get from the top step of one flight to the bottom step of the next.

U-Shaped Stair— The U-shaped stair, also called a switchback stair, has a landing about half a flight up, and the flights run in opposite directions. The area of the stairway is increased over a straight-run stair by the area of the landing (less one step), but the top step of one flight is adjacent to the bottom step of the next. This arrangement saves circulation space at each floor level and makes this stair more efficient overall for multistory buildings than the straight-run stair.

|

|

L-Shaped stair—The L-shaped stair is not so common as the straight or U-shaped stair because it lacks the simplicity of the straight-run stair and the efficiency of the U-shaped stair. It can, however, be useful in tight spots, as it takes up less floor space than a U-shaped stair and requires less length than a straight-run stair. The framing of the opening in the floor for this stairway can be atypical because of its L-shape. A framed wall under one side of the floor projecting into the L or a column under the floor at the bend in the L is the most common way to support this floor.

|

|

Winder stairs at the bend in the L (or at the bend in a U-shaped stair) are common, but for reasons of safety, should not be allowed to be less than 6 in. deep at the narrow end (verify with local codes).

|

|

Spiral Stair – A spiral stair saves space. It is most appropriate for accessing mezzanines and lofts where furniture and other large items may actually be hoisted from floor to floor by means other than the stairway. Spiral stairs usually have special code requirements that are somewhat less restrictive than standard stairs. They are usually prefabricated, often of metal or wood kits. Their details are idiosyncratic and not included in this book.

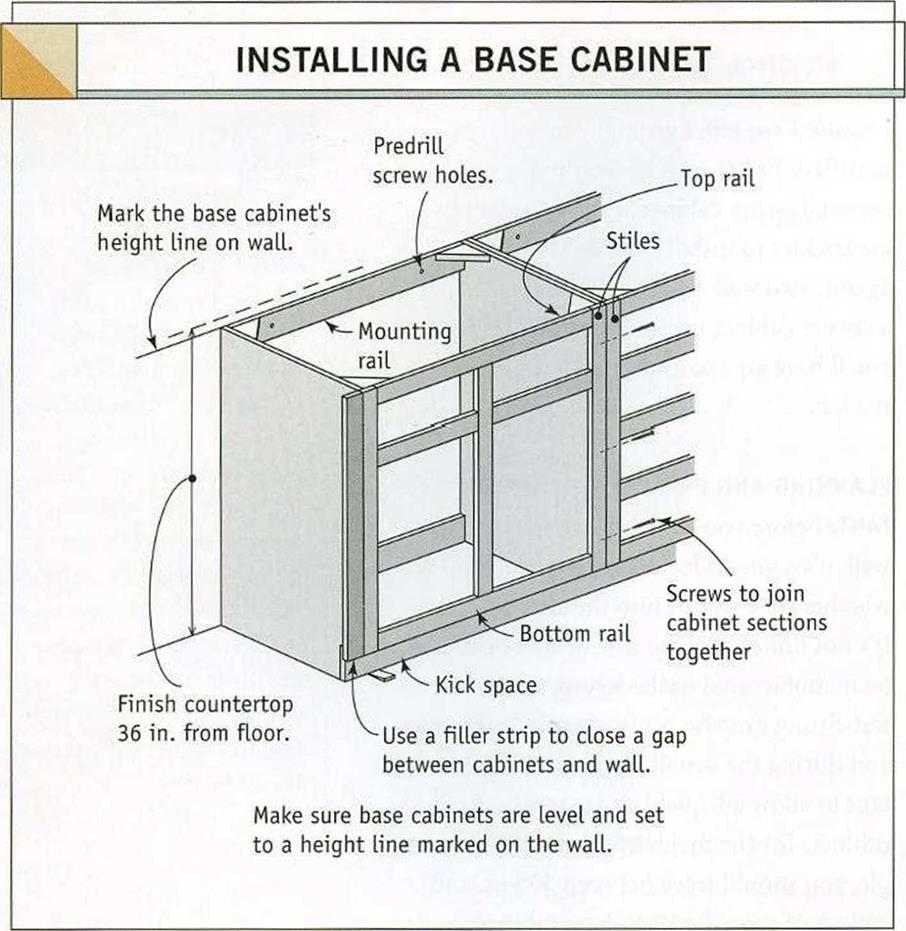

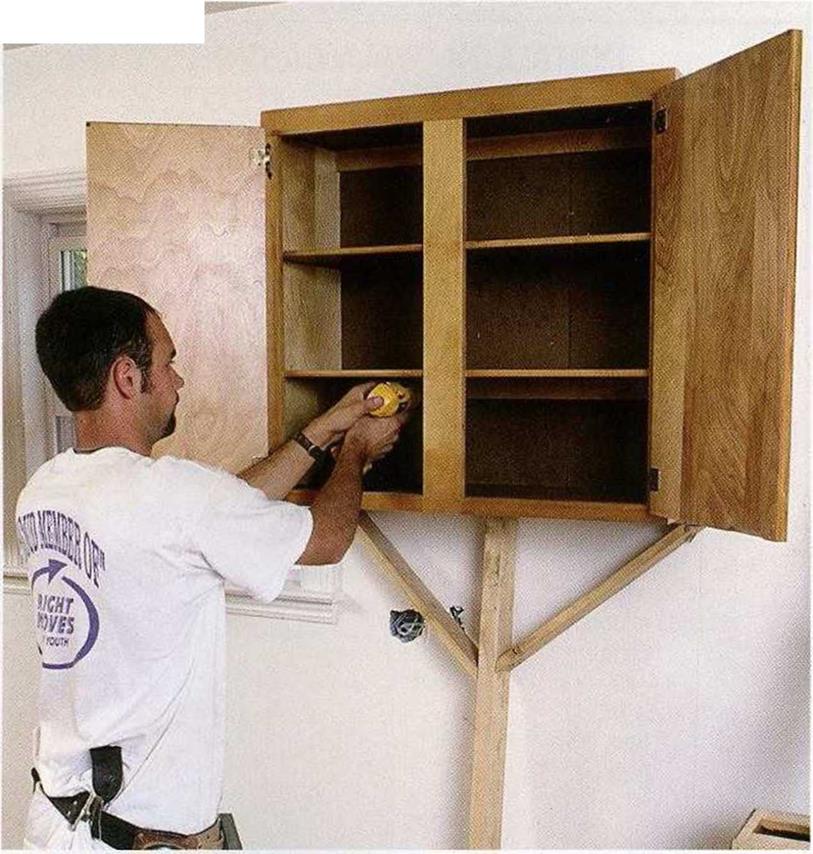

installed, use a level to find the highest spot on the floor, then measure up the wall near that spot. The standard height of base cabinets without a countertop is usually 34/ in. or 35/ in., depending on the manufacturer (see the illustration above).

installed, use a level to find the highest spot on the floor, then measure up the wall near that spot. The standard height of base cabinets without a countertop is usually 34/ in. or 35/ in., depending on the manufacturer (see the illustration above).

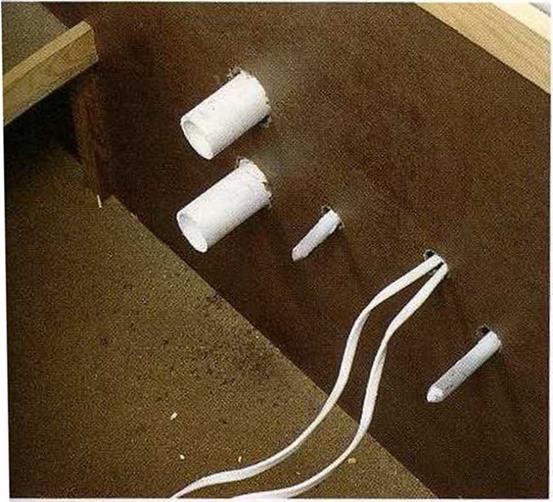

MAKE ROOM FOR UTILITIES BENEATH THE SINK. Holes must be drilled in the back of sink cabinets to make room for pipes and electrical wires.

MAKE ROOM FOR UTILITIES BENEATH THE SINK. Holes must be drilled in the back of sink cabinets to make room for pipes and electrical wires.

Notice, in Fig. 5.33, that the original red pine rafter twisted slightly after construction, as red pine is inclined to do. I was able to straighten the rafter extension by making a biased cut out of the new rafter. This made for a tricky chainsaw cut. The key to success in this sort of thing is to mark the angle correctly on the piece to be cut. And the key to marking it correctly is to double – and triplecheck your angles and measurements. As I tend towards a slight dyslexia on this sort of thing, I would explain what I was doing to willing ears such as Rohan’s. He picks up quickly on wooly-minded thinking.

Notice, in Fig. 5.33, that the original red pine rafter twisted slightly after construction, as red pine is inclined to do. I was able to straighten the rafter extension by making a biased cut out of the new rafter. This made for a tricky chainsaw cut. The key to success in this sort of thing is to mark the angle correctly on the piece to be cut. And the key to marking it correctly is to double – and triplecheck your angles and measurements. As I tend towards a slight dyslexia on this sort of thing, I would explain what I was doing to willing ears such as Rohan’s. He picks up quickly on wooly-minded thinking.

Each plate would require eight half-inch by з^-іпсії (1.2- by 9.0- centimeter) hex-headed lag screws. Six times eight is 48. It was quite a bit cheaper to buy two boxes with 25 screws per box than to buy 48 pieces out of the bin. So I have two left over.

Each plate would require eight half-inch by з^-іпсії (1.2- by 9.0- centimeter) hex-headed lag screws. Six times eight is 48. It was quite a bit cheaper to buy two boxes with 25 screws per box than to buy 48 pieces out of the bin. So I have two left over.

Figure 8.16 The city of Huzhou, near the south bank of Taihu lake. This city is linked to Hangzhou and to the Grand Canal by a network of canals. “It is one of the largest and most considerable cities of China, due to its richness, its commerce, the fertility of its land, and by the beauty of its waters and mountains.” (du Halde, 1735 – ancient archives ENPC).

Figure 8.16 The city of Huzhou, near the south bank of Taihu lake. This city is linked to Hangzhou and to the Grand Canal by a network of canals. “It is one of the largest and most considerable cities of China, due to its richness, its commerce, the fertility of its land, and by the beauty of its waters and mountains.” (du Halde, 1735 – ancient archives ENPC).