AESTHETIC CONSIDERATIONS

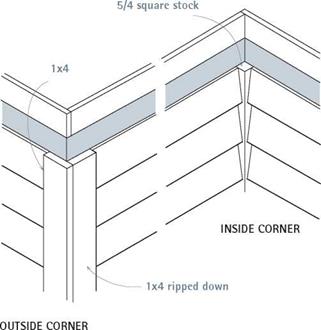

While highway bridges are utilitarian structures, they are visible to the public and therefore should be pleasing to the eye. At the outset of design, one should be conscious of the aesthetic qualities of the structure, lest one end the project saying (after Shelley), “Look on my works, ye Mighty, and despair!”

Some basic guidelines that were adopted by the Ohio Department of Transportation (DOT), Bureau of Bridges and Structural Design, and are included in its Bridge Design Manual illustrate the commonsense approach that can be taken to apply this consciousness:

Aesthetics. Each structure should be evaluated for aesthetics. Normally it is not practical to provide cost premium aesthetic treatments without a specific demand; however, careful attention to the details of the structure lines and forms will generally result in a pleasing structure appearance.

Aesthetic bridge guidelines containing useful and practical information on how aesthetic quality can be recognized and incorporated in bridge design at minimal cost are as follows:

a. Avoid mixing structural elements, for example concrete slab and steel beam superstructures or cap and column piers with wall type piers.

b. In general, continuous superstructures shall be provided for multiple span bridges. Where intermediate joints cannot be avoided, the depth of spans adjacent to the joints preferably should be the same. Avoid the use of very slender superstructures over massive piers.

c. Abrupt changes in beam depth should be avoided where possible. Whenever sudden changes in the depth of the beams in adjacent spans are required, care should be taken in the development of details at the pier.

d. The lines of the structure should be simple and without excessive curves and abrupt changes.

e. All structures should blend in with their surroundings.

One of the most significant design factors contributing to the aesthetic quality of the structure is unity, consistency, or continuity. These qualities will give the structure an appearance of a design process that was carefully thought out.

The aesthetics of the structure can generally be accomplished within the guidelines of design requiring only minimum special designs and minor project cost increase. As special situations arise preliminary concepts and details should be developed and coordinated with the Bureau of Bridges and Structural Design.

Some states have adopted, in principle if not in writing, a similar philosophy in regard to aesthetics of their bridges. California, for example, is known and admired for applying some degree of architectural attention to all of its bridges. Some agencies, however, seem to neglect aesthetics, particularly in regard to the very visible piers of grade-separation bridges. Here the primary objectives seem to be standardization of shape to facilitate computer design, and emphasis on straight, flat lines to obtain minimum cost of forming. These objectives are achieved at a price—ungraceful substructures not in keeping with the lines of the superstructure.

![NAILING TOGETHER THE WINDOW FRAME ASSEMBLIES Подпись: Door and window assemblies are nailed together and ready to be installed between the top and bottom wall plates. [Photo © Larry Haun]](/img/1312/image312.gif) the ground, add lots of compost, plant good seeds, mulch well, and nurture young plants, you can’t help but grow outstanding vegetables. The situation is similar when you’re framing walls. If you take the time to lay out, cut, and correctly position every part of every wall, then the actual framing will go smoothly and you’ll produce a quality building.

the ground, add lots of compost, plant good seeds, mulch well, and nurture young plants, you can’t help but grow outstanding vegetables. The situation is similar when you’re framing walls. If you take the time to lay out, cut, and correctly position every part of every wall, then the actual framing will go smoothly and you’ll produce a quality building.