STACK VENTS, VENT STACKS, AND RELIEF VENTS

Stack vents, vent stacks, and relief vents require more information for sizing. Specifically, you must know the fixture-unit load on a drain before you can determine vent sizing and developed lengths. Once you have calculated the fixture units, a sizing table can be used to give you your sizing information. The table shown in Figure 5.31 is the type of table that would be used to define the requirements of stack vents, vent stacks, and relief vents. Like the other tables, this one is self-explanatory. To prove this, size the diameter and maximum length of a vent stack that will serve 20 fixture units with a drain diameter of two inches. Assume that you want your vent pipe to have a diameter of one and a half inches. The answer is that your vent size is okay, as long as you don’t extend it more than 50 feet. If you need more distance, increase the size of the vent to a 2-inch diameter and feel free to run the vent up to 150 feet. The table is easy to use, but you must be able to calculate the load of fixture units. How will you do that? I’ll show you.

Most codebooks will provide you with some form or a chart or table that identifies fixture-units for drainage piping. A table like the one in Figure 5.32 is quite helpful. By looking at such a table, you can quickly determine the load, in terms of fixture units, that an individual fixture puts on a drain. For example, a bidet carries a fixture-unit rating of 2. A drinking fountain is rated for one half of a fixture unit. A residential water closet is worth 4 fixture units. By using this type of table to assign fixture-unit ratings to all fixtures being served by a drain, you can then arrive at a number to use with the vent-sizing table. For fixtures that are not listed, you can use a generic table, like the one in Figure 5.33, to assign ratings for fixture units.

Most codebooks will provide you with some form or a chart or table that identifies fixture-units for drainage piping. A table like the one in Figure 5.32 is quite helpful. By looking at such a table, you can quickly determine the load, in terms of fixture units, that an individual fixture puts on a drain. For example, a bidet carries a fixture-unit rating of 2. A drinking fountain is rated for one half of a fixture unit. A residential water closet is worth 4 fixture units. By using this type of table to assign fixture-unit ratings to all fixtures being served by a drain, you can then arrive at a number to use with the vent-sizing table. For fixtures that are not listed, you can use a generic table, like the one in Figure 5.33, to assign ratings for fixture units.

|

|

|

|

FIGURE 5.30 ■ Individual and branch vent sizing table for horizontal soil and waste branches. [Courtesy of Standard Plumbing Code)

|

Size of soil or |

Diameter of vent required (in) |

|||||||||

|

(in) |

connected |

lVi |

1У2 |

2 |

2У2 |

3 |

4 |

5 |

6 |

8 |

|

V/i |

2 |

30 |

||||||||

|

1V5> |

8 |

50 |

150 |

|||||||

|

1У2 |

10 |

30 |

100 |

|||||||

|

2 |

12 |

30 |

75 |

200 |

||||||

|

2 |

20 |

26 |

50 |

150 |

||||||

|

2’/2 |

42 |

— |

30 |

100 |

300 |

|||||

|

3 |

10 |

— |

30 |

100 |

200 |

600 |

||||

|

3 |

30 |

— |

— |

60 |

200 |

500 |

||||

|

3 |

60 |

— |

— |

50 |

80 |

400 |

||||

|

4 |

100 |

– |

– |

35 |

100 |

260 |

1000 |

|||

|

4 |

200 |

— |

— |

30 |

90 |

250 |

900 |

|||

|

4 |

500 |

— |

— |

20 |

70 |

180 |

700 |

|||

|

5 |

200 |

— |

— |

— |

35 |

80 |

350 |

1000 |

||

|

5 |

500 |

— |

— |

— |

30 |

70 |

300 |

900 |

||

|

5 |

1100 |

– |

– |

– |

20 |

50 |

200 |

700 |

||

|

6 |

350 |

— |

_ |

_ |

25 |

50 |

200 |

400 |

1300 |

|

|

6 |

620 |

— |

— |

— |

15 |

30 |

125 |

300 |

1100 |

|

|

6 |

960 |

— |

— |

— |

—• |

24 |

100 |

250 |

1000 |

|

|

6 |

1900 |

— |

— |

— |

— |

20 |

70 |

200 |

700 |

|

|

8 |

600 |

– |

– |

– |

– |

– |

50 |

150 |

500 |

1300 |

|

8 |

1400 |

_ |

_ |

_ |

__ |

_ |

40 |

100 |

400 |

1200 |

|

8 |

2200 |

— |

— |

— |

— |

— |

30 |

80 |

350 |

1100 |

|

8 |

3600 |

— |

— |

— |

— |

■ |

25 |

60 |

250 |

800 |

|

10 |

1000 |

— |

— |

— |

— |

— |

— |

75 |

125 |

1000 |

|

10 |

2500 |

– |

– |

– |

– |

– |

– |

50 |

100 |

500 |

|

10 |

3800 |

_ |

_ |

— |

_ |

— |

— |

30 |

80 |

350 |

|

10 |

5600 |

— |

— |

— |

— |

— |

— |

25 |

60 |

250 |

|

1 in = 25.4 mm 1 ft = 0.3048 m |

![]() FIGURE 5.31 ■ Maximum length of stack vents, vent stacks, and relief vents. (Courtesy of Standard Plumbing Code)

FIGURE 5.31 ■ Maximum length of stack vents, vent stacks, and relief vents. (Courtesy of Standard Plumbing Code)

|

|

Fixture type |

Fixture-unit value as load factors |

Minimum size of trap (in) |

|

Bathroom group consisting of water closet, lavatory, and bathtub or shower |

6 |

|

|

Bathtub1 (with or without overhead shower) or whirlpool attachments |

2 |

lVz |

|

Bidet |

2 |

Nominal 1У2 |

|

Combination sink and tray |

3 |

T/2 |

|

Combination sink and tray with food disposal unit |

4 |

Separate traps ІУ2 |

|

Dental unit or cuspidor |

1 |

1У4 |

|

Dental lavatory |

1 |

1У4 |

|

Drinking fountain |

‘/2 |

1 |

|

Dishwashing machine2 domestic. |

2 |

1У2 |

|

Floor drains5 |

1 |

2 |

|

Kitchen sink, domestic |

2 |

1У2 |

|

Kitchen sink, domestic with food waste grinder and/or dishwasher |

3 |

1У2 |

|

Lavatory4 |

1 |

Small P. O. l’/4 |

|

Lavatory4 |

2 |

Large P. O. 1У2 |

|

Lavatory, barber, beauty parlor |

2 |

ІУ2 |

|

Lavatory, surgeon’s |

2 |

ІУ2 |

FIGURE 5.32 ■ Fixture units per fixture or group. (Courtesy of Standard Plumbing Code)

vcadrc Volume of air voids in coarse aggregate

vcadrc Volume of air voids in coarse aggregate

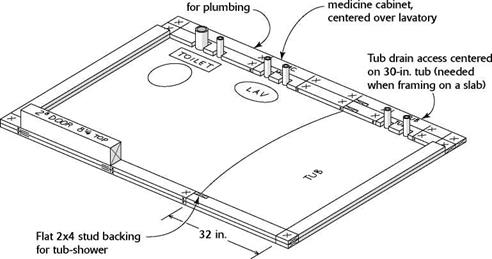

rior Trim tips

rior Trim tips

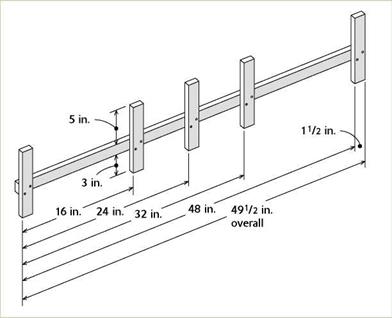

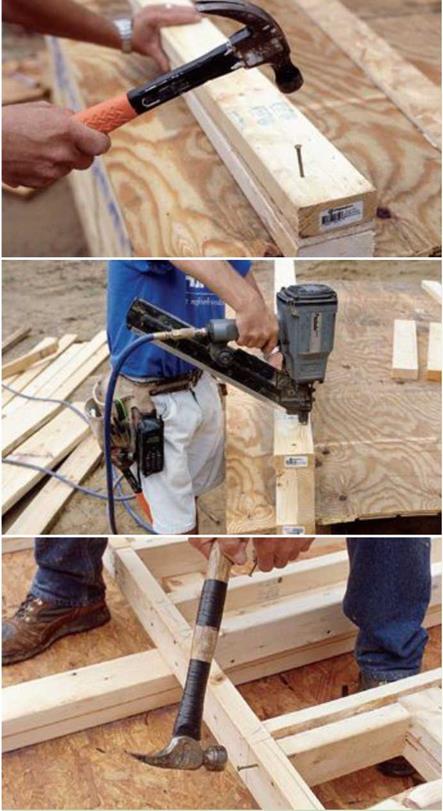

Start the stud layout at one end of a long exterior wall. Place the layout stick on the outside edge of the plates, with the first tab 3/4 in. beyond the end of the wall. This sets up a 16-in.- o. c. or a 24-in.-o. c. layout that will accommodate the 4-ft.-wide sheathing sheets (see the photo above). Mark both sides of the remaining tabs to note the locations of the next three studs. Move the layout stick, line up the end tab with the last mark, and mark again. If you’re nailing a sheet of OSB at the outside corners for bracing, make sure you lay out a stud 4 ft. from each corner in both directions.

Start the stud layout at one end of a long exterior wall. Place the layout stick on the outside edge of the plates, with the first tab 3/4 in. beyond the end of the wall. This sets up a 16-in.- o. c. or a 24-in.-o. c. layout that will accommodate the 4-ft.-wide sheathing sheets (see the photo above). Mark both sides of the remaining tabs to note the locations of the next three studs. Move the layout stick, line up the end tab with the last mark, and mark again. If you’re nailing a sheet of OSB at the outside corners for bracing, make sure you lay out a stud 4 ft. from each corner in both directions.

If the size of the fixture drain was three inches in diameter, with a 3-inch trap, and one-eighth of an inch of fall per foot, the vent could be up to 10 feet from the trap. Obviously, this type of table is easy to understand and to work with.

If the size of the fixture drain was three inches in diameter, with a 3-inch trap, and one-eighth of an inch of fall per foot, the vent could be up to 10 feet from the trap. Obviously, this type of table is easy to understand and to work with.

sheathing, so siding (or casing) is butted to the sides of these protruding jambs.

sheathing, so siding (or casing) is butted to the sides of these protruding jambs.