Moisture Content Effect on Bearing Capacity – a Danish Study

Relationships between bearing capacity and moisture content were studied in the Danish Road Testing Machine (ALT-facility) (Krarup, 1995). A typical Danish pavement was built in the facility, and for almost one year the only condition that was changed was the level of the water table. No load was applied except for FWD – measurements. The layer stiffness moduli (E-values) of the pavement layers were calculated from FWD-measurements with the program ELMOD (Dynatest, 1989). Based on the test results, a relationship between E-value and suction, pore pressure and degree of saturation was established. Simple linear regression describes the

|

Slighty clayey sand – Noucelles 1. pd = 1.70 Mg/m3 : M = 111.1 + 0.119 s R = 0.980, N = 11 2. pd = 1.62 Mg/m3 : M = 113.1 + 0.084 s R = 0.971, N = 13 Silt – Sterrebeek 3. pd = 1.75 Mg/m3 : Mr = 80.4 + 0.092 s R = 0.918, N = 26 4. pd = 1.59 Mg/m3 : M= 73.7 + 0.064 s R = 0.900, N = 15 Slighty clayey sand – Noucelles 5. pd = 1.70 Mg/m3: G = 42.1 + 0.074 s R = 0.868, N = 10 6. pd = 1.62 Mg/m3 : G = 47.3 + 0.055 s R = 0.879, N = 13 Silt – Sterrebeek 7. pd = 1.70 Mg/m3 : G = 34.0 + 0.078 s R = 0.953, N = 14 8. pd = 1.62 Mg/m3 : G = 29.3 + 0.049 s R = 0.942, N = 11 iSS * lem I |

Suction head, s, (cm)

Fig. 10.18 Correlations between the resilient modulus and the suction for the two soils analyzed for a confining pressure of 20 kPa and a deviatoric stress of 20 kPa (BrUll, 1983). Figure courtesy of the Belgian Road Research Centre

Note: Mr = Resilient Modulus (MPa), G = Shear Modulus (MPa), R = coefficient of correlation, N = number of data points, s = suction (cm), light dotted lines show 95% confidence limits for Mr.

relation between the value of the E-value and suction measured by the tensiometer in the form: E = B1 + B2 x s, where

• E is the layer E-value in MPa from the ELMOD calculation;

• B1 and B2 are constants; and

• s is the measured suction in kPa.

The regressions reveal high levels of R-squared within the range of the measured suction values for all unbound layers. The measured values and the linear regression lines from three of the tensiometer depths are plotted in Fig. 10.20.

When calculating the stress in a pavement (a continuous body), the stress according to Boussinesq is independent of the E-modulus of the material. Combining this statement with Terzaghi’s principle of effective stress, it becomes unpredictable to what extent E-values from FWD-tests relate to positive pore pressure measured in standpipes. Positive pore water pressure only appears in what is considered to be a saturated condition. In the Krarup study, the upper pavement layers only became saturated for very short periods and water/suction versus time series exist for this granular base course layer data.

The available measured data, linear and linear-exponential regressions were tested on the data to investigate any dependency. The linear regression came up with a R-squared value ranging from 0.56 to 0.88, whereas the linear-exponential regression had the best fit at 0.72. The data and the linear regressions were plotted in Fig. 10.21. Note the much lower values of stiffness were determined in-situ than those typically measured in laboratory triaxial assessments (cf. Fig. 10.12 for example).

The reason for the decrease of the lower unbound layer material stiffness over the monitoring period is expected to be the water that adheres to the surface of the mineral’s granular materials, more than any pore water pressure phenomenon.

Saturation: Saturation and E-values are not expected to reveal a linear relationship, as the change in E-value dependent on degree of saturation occurs at a certain level of saturation determined by the void size distribution. The results plotted in Fig. 10.22 are derived from time series and are not scattered data points. During the monitoring period the saturation increased and decreased, so the curves should be read from left to right and then back again so as to follow time.

The two time series of saturation data from 20 to 40 cm below surface are plotted with the E-values assigned to the sub-base layer, and therefore plotted with the same

set of E-values. Figure 10.23 shows that granular base course and sub-base layers tended to have threshold E-values in the test pavement. Keeping the low E-values of the subgrade at the construction time in mind, the E-value of the natural till subgrade might continue to decrease as long as the water table is above the material.

As a rather strong relationship between E-value and suction was confirmed from the measurements, the relation between suction and saturation becomes interesting. In soil water research the relationship is the so-called soil-water characteristic curve or the retention curve. From experiments in the laboratory the relationship can be found for small soil samples. Data measured in the test pavement were plotted as Fig. 10.23.

![Correlated-sampling techniques Подпись: Example 6.12 Refer to the pump reliability problem that has been studied in previous examples. Now consider a second pump the time-to-failure PDF of which also is an exponential distribution but has a different parameter of в = 0.0005/h. Estimate the difference in the failure probability between the two pumps over the time interval [0, 200 h] using the correlated-sampling technique with n = 2000. Solution Again, the sample-mean Monte Carlo method with a uniform distribution U(0, 200) is applied as in Example 6.7. In this example, the same set of standard uniform random variates {u1, U2,..., U2000} fromU(0,1) is used to estimate the failure probabilities for the two pumps as](/img/1312/image959_1.png)

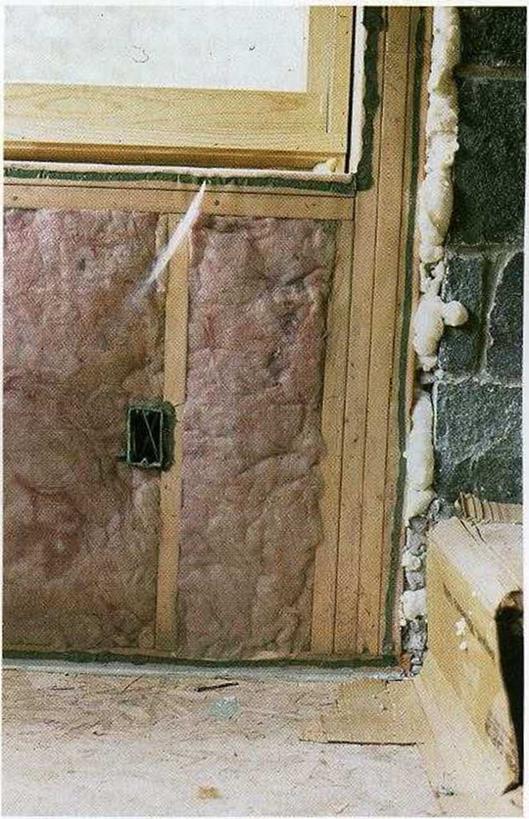

To prevent leakage at electrical outlets, use airtight boxes. Available at most electrical – supply stores, airtight boxes have a broad, flexible gasket around the front edge, where a poly barrier can be sealed easily. Alternatively, you can simply cut a box-size opening in the poly and seal the poly to the electrical box with a bead of caulk (see the photo below).

To prevent leakage at electrical outlets, use airtight boxes. Available at most electrical – supply stores, airtight boxes have a broad, flexible gasket around the front edge, where a poly barrier can be sealed easily. Alternatively, you can simply cut a box-size opening in the poly and seal the poly to the electrical box with a bead of caulk (see the photo below).

their own doors also makes it possible to share a bathroom during morning rush hours, yet still have privacy.

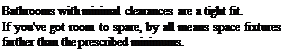

their own doors also makes it possible to share a bathroom during morning rush hours, yet still have privacy. preferable to sink rims or mounting clips that sit atop the counter. Nonporous baseboards or backsplashes allow you to swab comers with a mop or sponge without worrying about dousing walls or wood trim. Finally, you can mop bathroom floors in a flash if you have wall-hung toilets.

preferable to sink rims or mounting clips that sit atop the counter. Nonporous baseboards or backsplashes allow you to swab comers with a mop or sponge without worrying about dousing walls or wood trim. Finally, you can mop bathroom floors in a flash if you have wall-hung toilets.

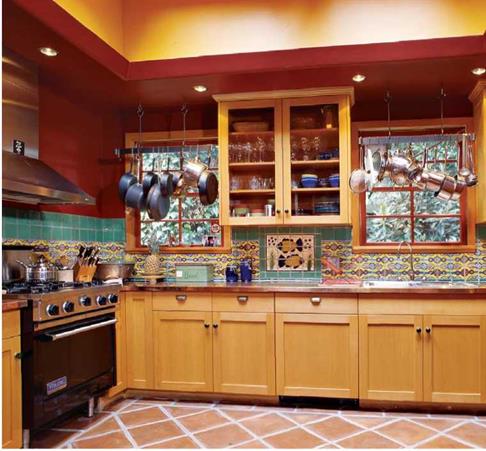

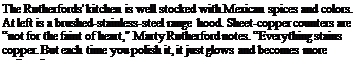

In general, be skeptical of range hoods that recirculate air through a series of filters rather than venting it outside.

In general, be skeptical of range hoods that recirculate air through a series of filters rather than venting it outside.