Exterior paint jobs can last 10 years or more if you’re fastidious about prep work and attentive to water-related building details. Key factors include proper flashing of windows, doors, and roof junctures; maintaining gutter systems; caulking gaps in exterior siding; and adequately venting excess moisture from interior spaces.

WHY PAINT FAILS

Before you sand or scrape anything, figure out why the paint is failing. . . and where.

Blistering is usually caused by painting over damp wood or an earlier coat of paint that isn’t dry. Blisters often contain water vapor, although "temperature blisters” are largely hot air, caused by painting a surface that was too hot. Scrape and sand blisters, allow the wood siding to dry thoroughly; then spot prime.

Peeling off in sheets, is blistering on a grand scale—sometimes an entire wall. Such peeling is most common on older homes lacking vapor barriers and occurs especially on siding outside bathrooms or kitchens, when excessive moisture migrates through the wall. If your old house has been retrofitted with insulation and a vapor barrier, peeling may indicate moisture trapped inside the walls and, possibly, rotted framing.

At the very least, add ventilator fans to exhaust water vapor. And on outside walls, drive thin plastic wedges behind the lap siding to help moisture escape.

Intercoat peeling, a new coat of paint separating from the old, is a classic case of poor prep work. Typically, chalky old paint was not scrubbed or sanded, and thus new paint could not adhere. Or, less often, the painter waited too long between the prime and finish coats. Scrape failed paint, sand, and wash the surface well, letting it dry before repainting.

Wrinkling is caused by applying paint too thickly, painting an exterior that is too cold, failing to thin paint sufficiently, applying paint before earlier coats are dry, or letting the paint get rained on before it cured adequately. Use a power sander to even out the surface before repainting.

Alligatoring or cross-grain cracking, is caused by too many layers of paint, usually old, oil-based paint. The thicker the paint, the less it can flex as siding expands and contracts. So the paint cracks—sometimes, all the way down to bare wood. Alligatoring may also be caused by painting over an undercoat that didn’t dry completely. In either case, it’s big trouble, because you’ll need to strip the paint down to bare wood and seal it with a primer-sealer before repainting. It may be easier to replace the siding

Chalking is a normal occurrence and isn’t a problem unless it’s excessive, usually the result of cheap paint. Because new paint won’t adhere well to a powdery residue, you must scrub and rinse the old surface and allow it to dry before repainting.

Rusty nail stains are common where siding nails were not galvanized. The fastest fix is sanding each stain lightly and priming with a rust- inhibiting primer like Kilz® stain blocker. For a longer-lasting repair, sand till you expose each nail head, use a nail set to sink each one Уз in. below the surface, prime with stain blocker, and fill with wood filler. Then sand and spot-prime before painting.

Tannin bleed through, a widespread brown staining, occurs when waterborne resins in woods, such as cedar and redwood, bleed through porous latex primers. Scrub the surface well and prime it with one or two coats of an oil-based (alkyd) primer like Kilz or Benjamin Moore Fresh-Start®. Paint what you like—latex

or oil-based—over that. At this writing, stainblocking acrylic latex primers show promise but don’t yet have the track record of oil-based stain-blocking primers. Get a second opinion from an up-to-date paint supplier.

Graying wood is a natural response to sunlight when siding is left unfinished or has been sealed with a clear finish that degrades. Never leave wood siding exposed to the elements—both because bare wood quickly degrades and because paint or clear finishes don’t adhere well to degraded wood. Sand and wash the surface, and reapply a clear finish with a UV-blocking agent. Clear finishes need to be reapplied every 2 years to 4 years. If that sounds like too much maintenance, prime the siding with an oil-based primer, and then switch to paint.

Mold and moss are common in damp climates, on north-facing and foliage-shaded walls and where lawn sprinklers hit the house. Siding that’s constantly damp can lead to structural rot. For starters, cut back foliage and the adjust sprinklers. Scrub moss off by hand, using a wire brush. Remove mold by applying a cleaner/ mildewcide such as Zinsser Jomax® before scrubbing or power washing the surface (but see the cautions later in this section). After the exterior has dried for about a week, prime as needed, and repaint with a paint containing a mildewcide.

PREPARING THE EXTERIOR

Before you start prep work, be sure to review this chapter’s earlier sections on equipment and lead – paint safety. Even though you’re working outside, wear a respirator mask when sanding or scraping paint and when working with solvents or paints of any kind. Likewise, when applying cleaning solutions (which can be caustic), wear rubber gloves and eye protection.

Prep work is prodigiously messy, so spread dropcloths out 8 ft. from your house to protect your lawn and shrubs. Otherwise, you’ll be picking paint scraps out of your grass for years or— even worse—exposing kids and pets to old lead-based paint. If it’s hot and sunny don’t cover your plants with plastic drop cloths; the plants will cook. Instead use fabric drop cloths, which shade plants, won’t tear, and are far less slippery to walk on. But if tests indicate lead paint, capture the debris in heavy 6-mil plastic tarps, which you can roll up and discard at the end of each day.

Washing surfaces. Before installing new wood siding, apply primer-sealer to front and back faces and to all edges. When that coat is dry, scuff-sand it with 100-grit sandpaper, and dust it

off with a whisk broom. Then install the siding before applying the top coats.

However, if the siding is already painted— even if the paint is in good shape—first wash it. Start by applying a house-cleaning solution, using a garden pump-sprayer. A dilute solution of TSP is often recommended, but urban houses may need a cleaning agent with a degreaser that will cut soot, automobile exhaust, and the like.

As noted earlier, if there’s mold present, use a cleaner with a mildewcide. Once the cleaner has had time to work, rinse it off with a garden hose and allow it to dry thoroughly for a week or so before painting. That’s a minimal wash.

To thoroughly wash and rinse an exterior, rent a pressure washer, which has a small boiler and a high-pressure electric pump. The rental company will recommend a detergent suitable for the unit and explain how to use it safely. For most cleaning jobs, 1,800 psi to 2500 psi (pounds per square inch) is specified—for softwoods like cedar or redwood, 1,000 psi to 1,500 psi. Tip sizes range from 0° (concentrated pressure that can easily damage siding) to 40° (a wider fan of water favored for light cleaning). In general, start with a low-pressure setting till you are familiar with the machine, and keep the spray wand moving. Note: Always spray downward if you’re cleaning lapped siding. Otherwise, you’ll force water underneath.

Scraping, sanding, spot-priming, caulking.

Once the siding has dried, hand-scrape the loose paint. For this, use a large scraper with 3-in.-wide blade, preferably one with a forward grip over

|

SAFETY

|

If you’re painting a whole house, the job will go much faster if you rent scaffolding. However, if you decide to use an extension ladder or two, follow these safety rules:

► Don’t place ladders near incoming electric service lines. When the air is moist, electricity can arc to nearby objects or people; so keep your distance.

► Securely position the ladder feet. Never ascend a ladder that lists to one side. On uneven ground, use a ladder with adjustable leveling feet, as shown on p. 36.

► Place the ladder bottom out from a building no more than one-quarter the ladder’s height.

► Wear hard-soled shoes so your feet won’t tire quickly on the ladder rungs.

|

Where a random-orbit sander won’t fit, use a palm sander, as shown, with 60-grit or 80-grit sandpaper. A palm sander is also handy for scuff-sanding old paint in good condition so new paint will adhere better.

|

|

|

Hand-scrape nooks and crannies that power tools can’t reach or could damage. Here, heat guns and chemical scrapers also make sense.

|

|

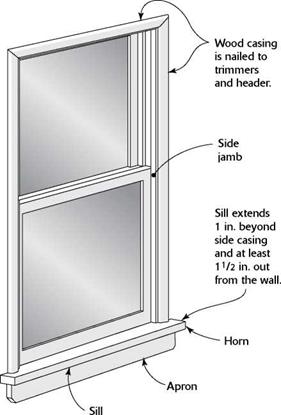

the blade. Be sure to scrape the lower edges of the clapboards and beneath the windowsills.

For hard-to-reach areas when siding abuts trim or where trim is curved or intricate, use a hand scraper with interchangeable blades. If paint doesn’t come off easily, that’s a good sign—it’s well adhered. However, if isolated areas of paint are too thick or obscure ornamental details, use a chemical stripper or a heat gun to remove more paint.

After scraping loose paint, use 80-grit sandpaper to feather out the edges of the remaining paint, smooth uneven surfaces, and scuff up surfaces so new paint will adhere well. For this work, an electric palm sander or random-orbit sander is a good tool, powerful yet light enough to use all day. If you’re prepping painted stucco, brick, or concrete, instead use a wire brush. When you’re done, brush off the dust with a hand broom.

If the paint is largely intact, you may not need to prime it, but you should spot-prime all areas you’ve scraped down to bare wood; exposed nail heads; and cracks, gaps, and holes you intend to fill or caulk. Spot-priming blocks nail stains, seals wood from moisture, and provides a better surface for filler or caulk to adhere to. Use either an exterior-grade polyurethane, a paintable

acrylic, or a multipolymer caulk; don’t use silicone caulk because paint won’t stick to it.

This is also a good time to set and fill nail heads. Because wood filler shrinks as it dries, slightly overfill the holes. When the filler’s dry, sand it flush.

Where wood is badly deteriorated, you should replace it. If the trim has only localized rot and would be difficult to replace, scrape the loose matter away and impregnate the remaining area with an epoxy filler, such as the one shown in the photos on p. 134.

Stripping exterior paint. Stripping exterior paint is a nasty job. Fortunately, only a few paint conditions require stripping. One of those conditions is alligatoring, in which many layers of old,

cracked, oil-based paint resemble the skin of an alligator (see the photo on p. 457). In that case, before stripping to bare wood, get a bid to replace the siding. Labor costs should be less, to say nothing of the cost, mess, and health concerns of stripping lead-based paint. But if you decide to strip, wear a respirator mask, eye protection, and other apparel related to lead safety

Basically, stripping exterior paint becomes a choice between mechanical scrapers and chemicals. Sandblasting is too dirty, damaging, and dangerous to be done by anyone but an expert. Sanding and hand scraping a whole house is impossibly slow. And whereas heat guns are okay for small areas, the snail’s pace of stripping a house and the real risk of starting a fire make it a distant third option. So, in the end, some combination of mechanical scraping, chemicals, and limited hand scraping will probably serve best.

Mechanical scrapers such as AIT’s Paint Shaver® are serious, two-handed tools. Mechanical scrapers look somewhat like angle grinders, but have carbide-tipped rotary cutter – heads that shave paint from the clapboard faces and edges. The better models have vacuum attachments that collect most of the debris. Nonetheless, have tarps in place before starting; and to prevent cutter damage, set siding nails well below the surface. Thus, as you strip, you’ll need a hammer and a nail set to set the nails you missed. Also, be sure to install scaffolding so you can focus on the tool and not your footing.

To minimize damage to the siding, first set the tool’s depth adjustment so you need several passes to strip a surface. Finding the right cutting depth is largely a matter of trial and error, so first test the tool on an inconspicuous section. Beyond that, the real trick to mechanical scraping is keeping the steel shoe/guard flat to the surface so the tools strips evenly. Where a Paint Shaver won’t reach, use hand scrapers, a chemical stripper, or small mechanical scrapers like the Metabo™ Lf714S. When finished stripping, use a palm sander or a random-orbit sander with 50-grit to 80-grit sandpaper to smooth out the rough spots before washing, caulking, dusting, and priming.

Chemical strippers are most appropriate where trim is intricate or where you want to remove lead paint without dispersing particles into the air and soil. Strippers vary in strength, environmental impact, working time (4 hours to 48 hours), and method of application. Most often, chemicals are brushed on ‘/ in. to І4 in. thick, but it’s possible to apply some strippers with modified paint-spraying equipment. (If you spray, wear a full-face mask, gloves, and disposable coveralls.)

|

A mechanical scraper with a vacuum attachment is the tool of choice when you’ve got to strip exterior paint. But set the nail heads first, or you’ll chew up expensive scraper blades. Eye protection is a must.

|

Given enough time to work, chemical strippers should remove all paint layers in one application. To keep its stripper from drying out while working, Dumond Chemical’s Peel-Away® system comes with plasticized paper that’s pressed directly onto stripper-coated surfaces. Peel – Away’s active agent is lye, which is extremely caustic, so after stripping surfaces, you need to apply a special neutralizing solution before priming or painting. Another product, Back to Nature’s Multi-Strip™, is biodegradable, noncaustic, and water soluble. Thus it doesn’t need a neutralizing agent.

a

a

think thicker stock—1 in. or even 1/4 in.—looks better. If you want to see natural wood and your budget allows it, trim with oak, pine, or spruce, and seal it with clear finish. If you prefer a painted finish or your budget is very tight, choose medium-density fiberboard (MDF).

think thicker stock—1 in. or even 1/4 in.—looks better. If you want to see natural wood and your budget allows it, trim with oak, pine, or spruce, and seal it with clear finish. If you prefer a painted finish or your budget is very tight, choose medium-density fiberboard (MDF).